INSTALLATION

10

SH4 BASE-STANDARD

Minimum installation distance

The safety device must be positioned at a specific safety distance (Operating distance).

This distance must ensure that the dangerous area cannot be reached before the dan-

gerous motion of the machine has been stopped by the Safety Control System.

The safety distance depends on 4 factors, according to the EN ISO 13855 Standard:

• Response time of the ESPE (the time between the effective beam interruption and

the opening of the OSSD contacts)

• Machine stopping time including Safety Control System computing and actuating

time if present.

• ESPE resolution

• Approaching speed of the object to be detected

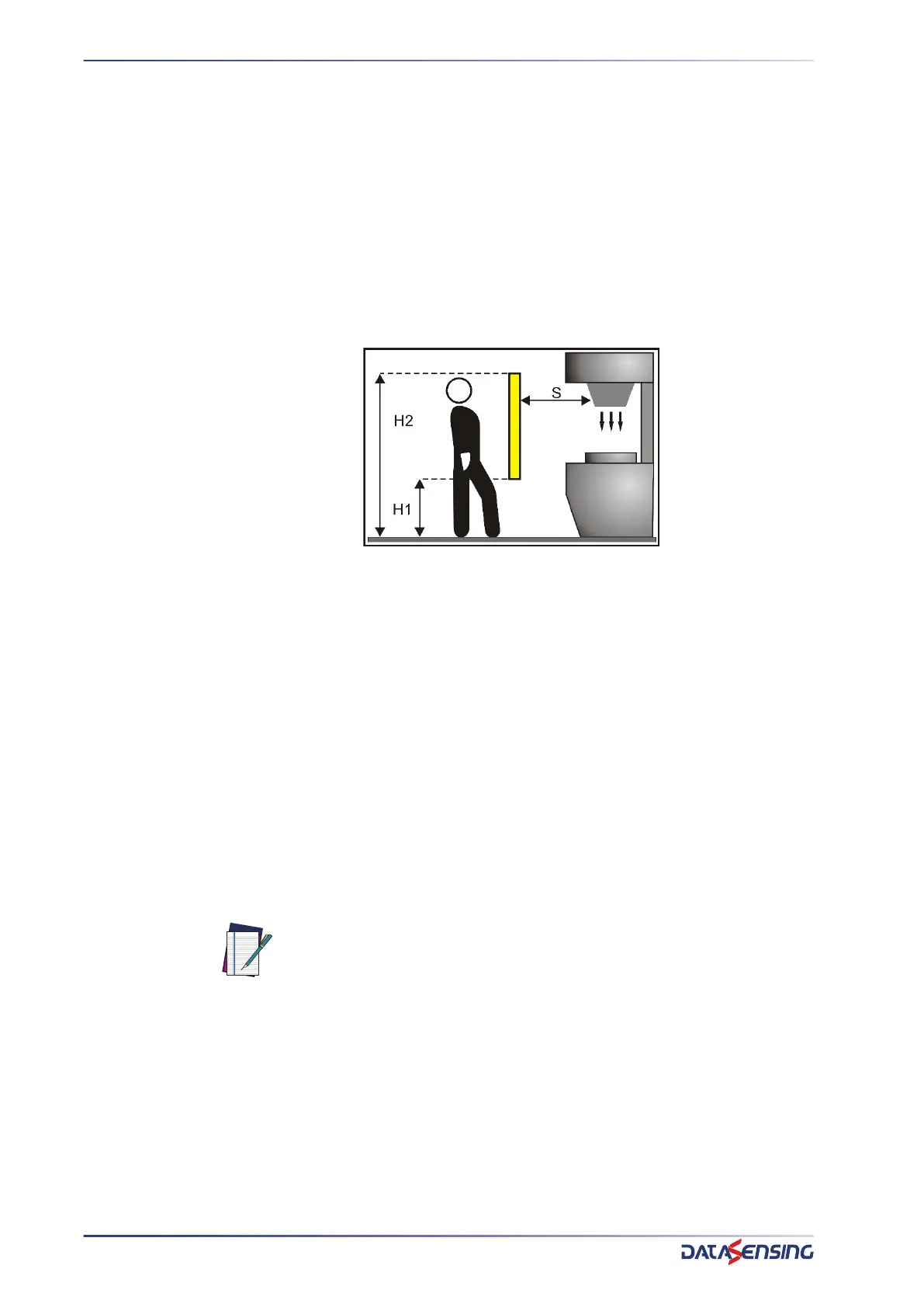

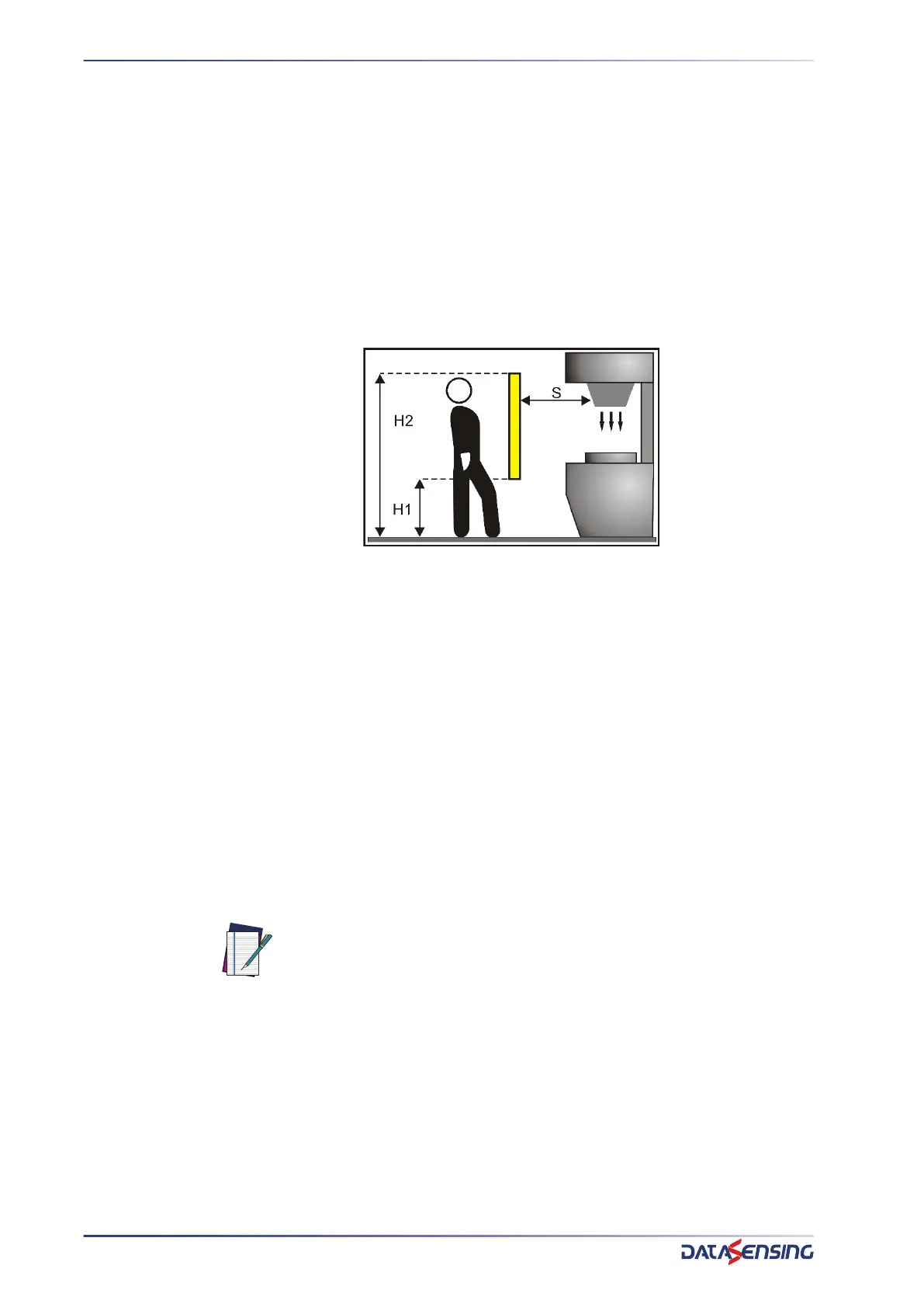

Figure 3: Installation distance (vertical positioning)

The following formula is used for the calculation of the safety distance:

S = K (t1 + t2) + C

where:

• S = Minimum safety distance in mm

• K = Speed of the object, limb or body approaching the dangerous area in mm/s

• t1 = Response time of the ESPE in seconds (see appendix “Technical Data”.)

• t2 = Machine stopping time in seconds (including the Safety Control System)

• C = Additional distance based on the possibility to insert the body or one of the

body parts inside the dangerous area before the protective device trips.

• C = 8 (R - 14) for devices with resolution ≤ 40 mm

• C = 850 mm for devices with resolution > 40 mm

• R = Resolution of the system

When devices with > 40 mm resolution are used, the height of the top beam has to be ≥

900 mm (H2) from machine supporting base while the height of the bottom beam has

to be ≤ 300 mm (H1).

NOTE: K value is:

2000 mm/s if the calculated value of S is ≤ 500 mm

1600 mm/s if the calculated value of S is > 500 mm

Loading...

Loading...