DVP02TK-S/DVP02TU-S Temperature Control Module Manual

2-26

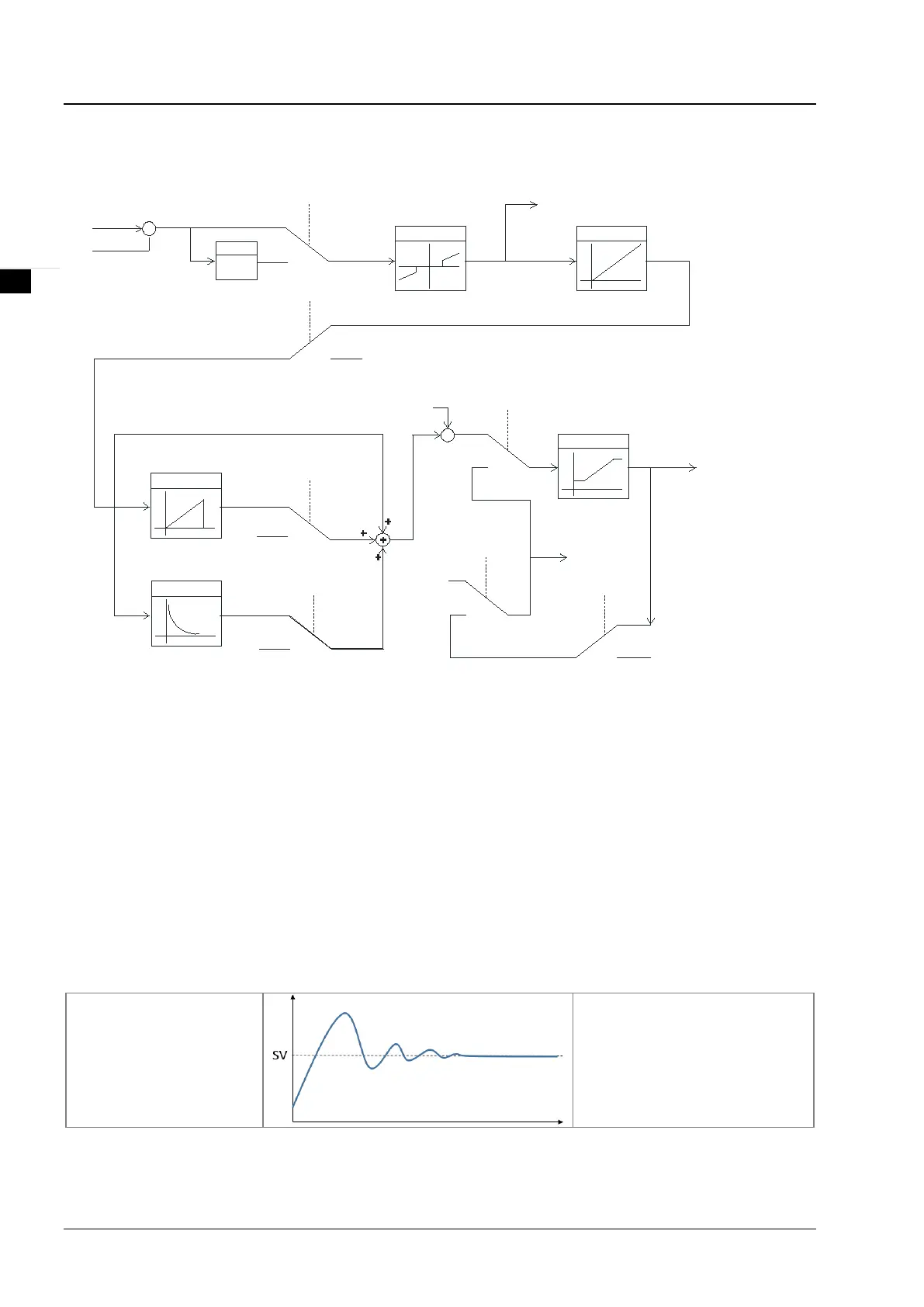

PID Block Diagram (Dependent)

SV

PV

+

-

+

PID-P

Kc_Kp

REVERSE

X(-1)

PID_DIR

0

1

E

DEAD BAND

ERR_DBW

PID-I

Ti_Ki

Kc_Kp

>0

<=0

0

Ti_Ki

>0

<=0

0

PID-D

Td_Kd, Tf

0

>0

<=0

Td_Kd

BIAS

PID_MAN

+

+

+

MV

MV_LIMIT

MV_MAX, MV_MIN

MOUT_AUTO

MOUT

MOUT

PID_MAN

MOUT

0

1

0

1

0

1

Note:

1. When tuning these 3 parameters, Kc_Kp, Ti_Ki and Td_Kd, set the Kc_Kp value first (according to their experiences),

and set the Ti_Ki and Td_Kd value to 0. When it can be controlled, users can increase the values of Ti_Ki and Td_Kd.

When the value of Kc_Kp is 1, it means that the proportional gain is 100%. That is, the error is increased by a factor of

one. When the proportional gain is less than 100%, the error is decreased. When th proportional gain is greater than

100%, the error is increased.

2. The parameters which have been tuned automatically are not necessarily suitable for every controlled environment.

Therefore, users can further modify the automatically-tuned parameters. However, it is suggested to modify the

values of Ti_Ki or Td_Kd only.

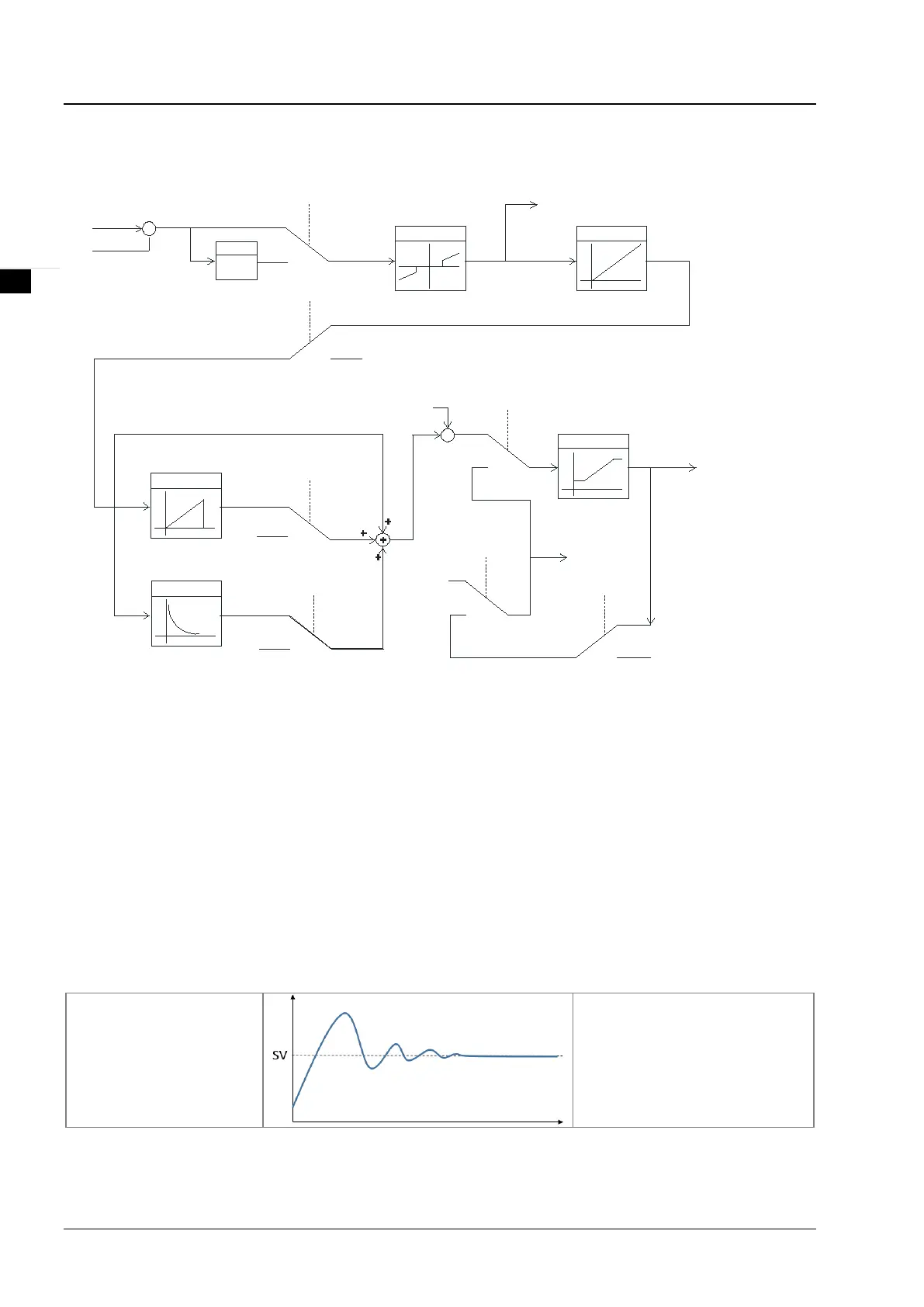

PID Tuning Guide:

P gain

Increase P gain

Achieve the target temperature

more quickly with a faster

convergence speed, while

Overshoot being increased.

Loading...

Loading...