7-2

7-1 Regular Maintenance and Check

For regular inspection, stop the machine operation, shut off the power, and remove the cover. Even

the power supply of theHybrid servo drive is disconnected, the filtering capacitor may still have

charging voltage which may take some time to be discharged completely. To avoid danger, it is

necessary to wait for the charging indicator to go off and use a voltmeter to test the voltage to confirm

that the voltage is below a safe value (≦ 25Vdc) before the inspection operation can be started.

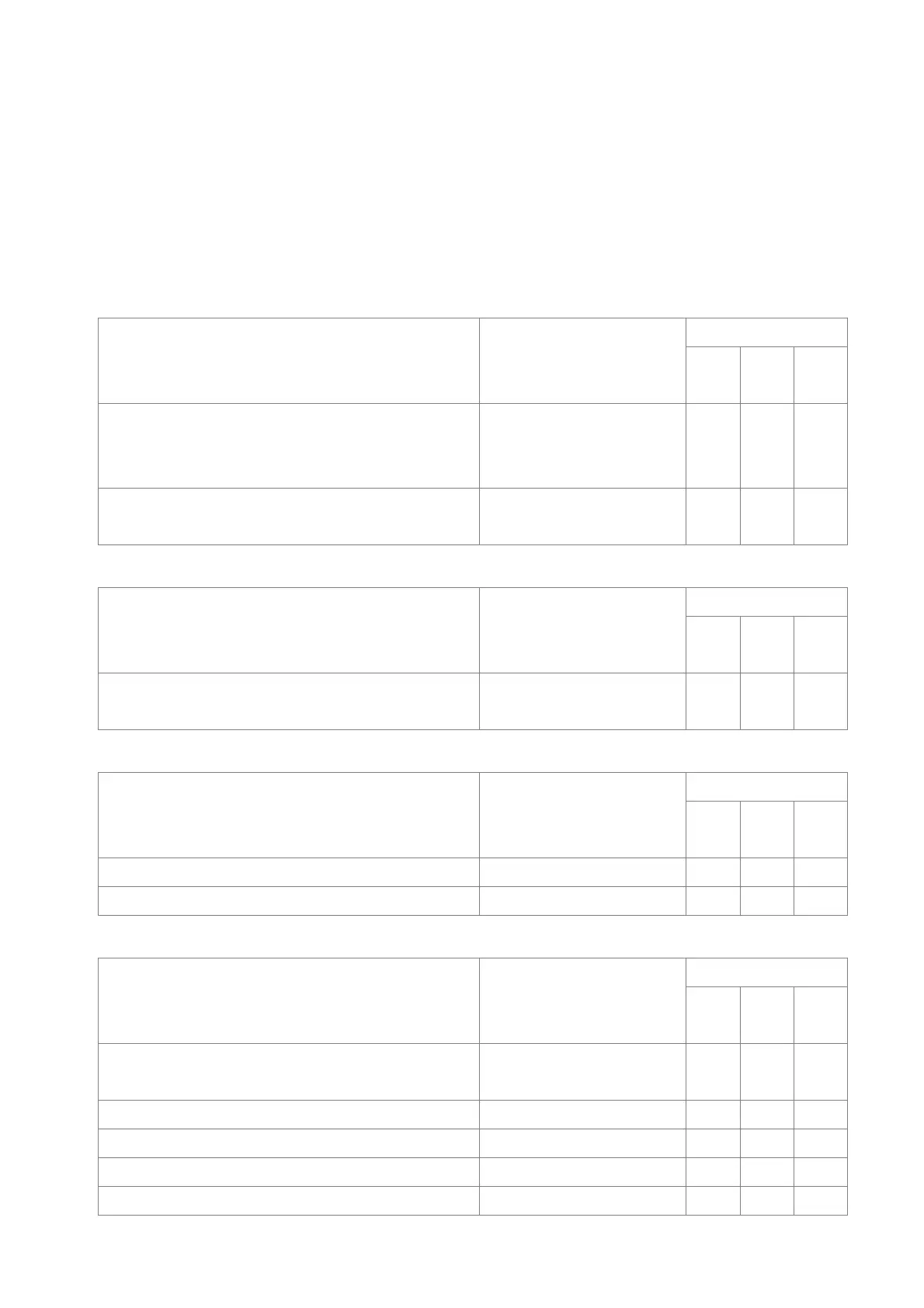

Surrounding Environment

Inspection Period

Inspection Item Inspection Method

Daily Half

year

One

year

Check the ambient temperature, humidity,

vibration, and if there is dust, gas, oil mist, water

droplets, etc.

Visual inspection and

measurement by

instrument

○

Is there any external object such as a tool or other

hazardous object around the device?

Visual inspection

○

Voltage

Inspection Period

Inspection Item Inspection Method

Daily Half

year

One

year

Are the voltages for the Main Circuit and the

Control Circuit correct?

Measurement by

instrument

○

Keypad Display Panel

Inspection Period

Inspection Item Inspection Method

Daily Half

year

One

year

Are the displayed messages readable? Visual inspection ○

Is there any omitted character? ○

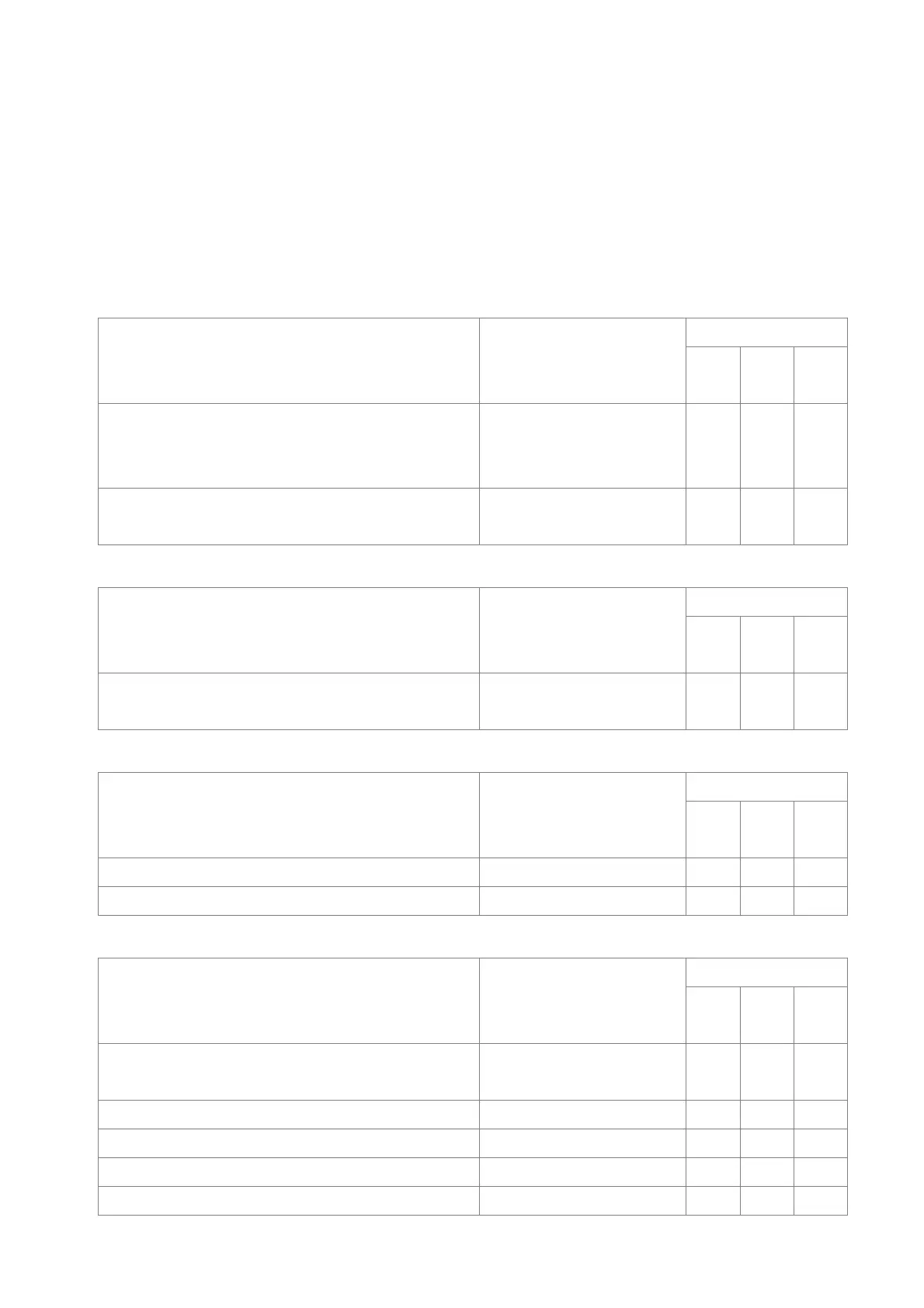

Mechanical Parts

Inspection Period

Inspection Item Inspection Method

Daily Half

year

One

year

Is there any abnormal sound or vibration? Visual and auditory

inspection

○

Are the bolts (fasteners) loose? Fastening

○

Is the part deformed or damaged? Visual inspection

○

Is the part discolored due to over heating? Visual inspection

○

Does the part have any dust or stain? Visual inspection

○

Loading...

Loading...