1-6

manufacturer). Over such an operating condition, the over-temperature of the motor may

easily occur. Let us take the factor 1.5 as an example, if the rated torque of the motor is 77

N-m, the motor with a power of 12kW* and a rated speed of 1500 rpm can be chosen.

*The power of the motor is calculated by using

)60/2()()(

××

rpmmNTWP

4. Maximum Current of the Motor

Example: Check the parameter kt (Torque/A) in the motor’s specifications, if kt = 3.37, the

maximum current is approximately 116/3.37 = 34A at the maximum torque of

116 N-m.

5. Selection of Matched Hybrid Servo Drive

Example: Look up the over-load capability for each Hybrid servo drive in the product

specification chart

If the holding pressure is at the maximum pressure of 17.5 Mpa, and a pump of

32cc/rev is used, the required motor current is approximately 34A

For such a current value, the following models can be chosen

VFD075VL43A-J, the overload may occur within 20 sec.

VFD110VL43A-J, the overload may occur approximately after 60 sec.

NOTE

If there is no suitable motor that meets the specifications, a motor with a higher rated value can be used instead.

For any information about the Hybrid servo drives or any assistance in detailed configuration of your company's

products, please contact the manufacturer.

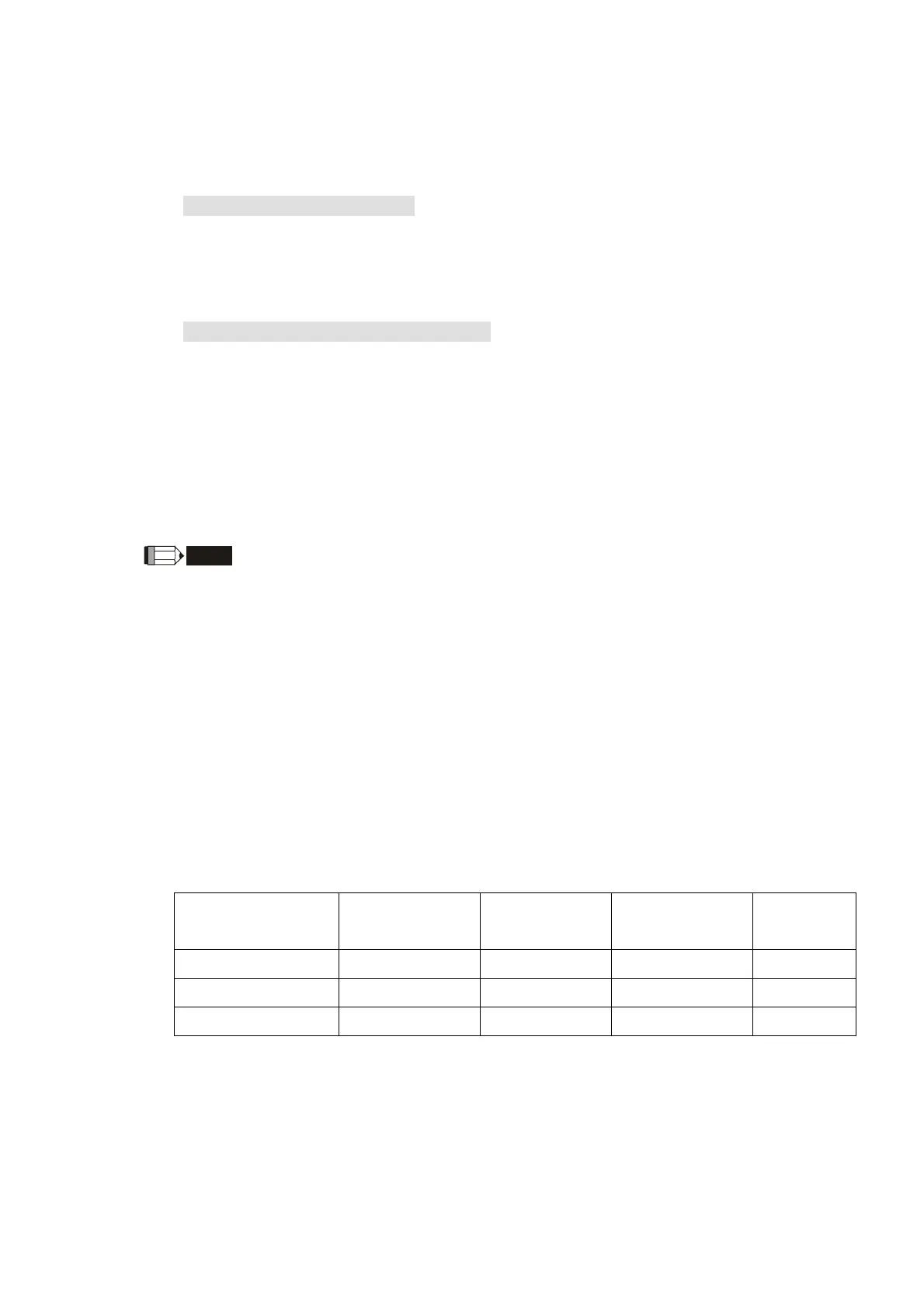

1-3-2 Selection of Pump for Hybrid Servo Motor

Select a pump with a suitable displacement based on the required flow rate and motor speed;

If low noise is required, you can choose the screw pump or internal gear type.If a high

volumetric efficiency is required, you can choose the piston pump or dual displacement

piston pump.

Comparison of Commonly Used Pump (This may vary for different pump manufacturers).

Type of Oil Pump

Volumetric

Efficiency

Flow Pulsation Rotation Speed Noise

Internal Gear Pump Low Medium Medium Low

Piston Pump High Low Low High

Screw Pump Medium High High Medium

Loading...

Loading...