Tub Back, Bearing and Cylinder Assembly

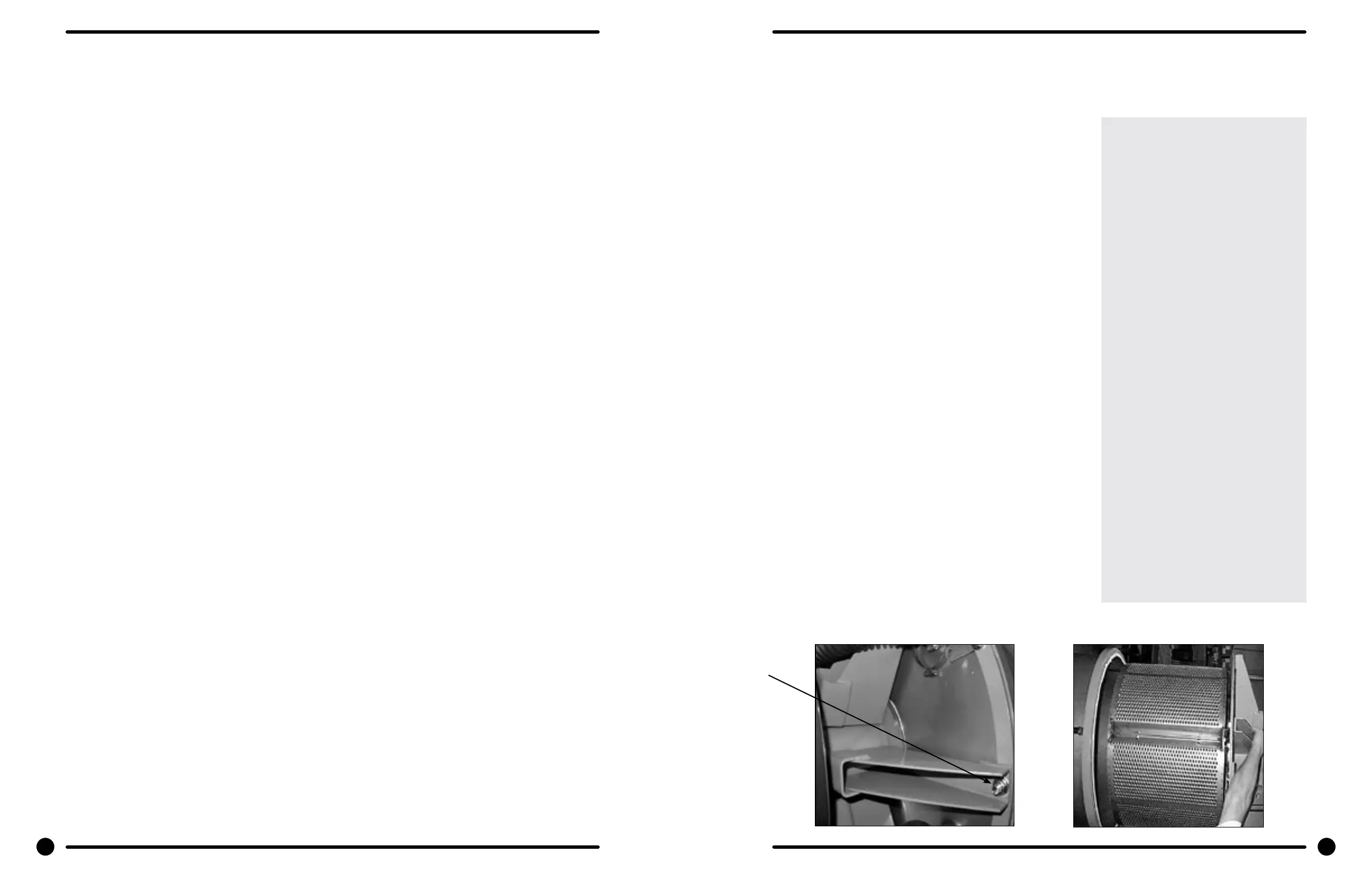

Basket assembly T-400 & T-600

Reassembly

Reverse the procedures to the left

paying attention to the following

areas

Step 1: Lay the washer on its front.

Note: Put a thick pad across

the front of the washer,

above the door, to protect

the handle and coin acceptor.

Step 2: Make sure the bearing

housing weep holes are

located at 12 o’clock and 6

o’clock.

Step 3: Clean the silicone rubber

from the back of the outer

tub and the perimeter of

the tub back where the two

meet. There is no gasket in

this area.

Step 4: Apply a new bead of silicone

rubber around the back of

the outer tub. (see picture)

Step 5: Lower the tub back, bearing

and cylinder assembly into

the washer outer tub.

Step 6: Torque all bolts according to

the following charts.

Step 7: Use a puller to remove the

pulley from the shaft.

Removal

Step 1: Remove the top and back panel as described.

Step 2: Move the rear channel, that the water valves mount to,

forward by removing the ve mounting screws.

Step 3: Remove the drive belt.

Step 4: Remove the overow hose, tub ll hose and pressure

switch hose from the back of the tub.

Step 5: Mark the tub back and bearing assembly for ease in

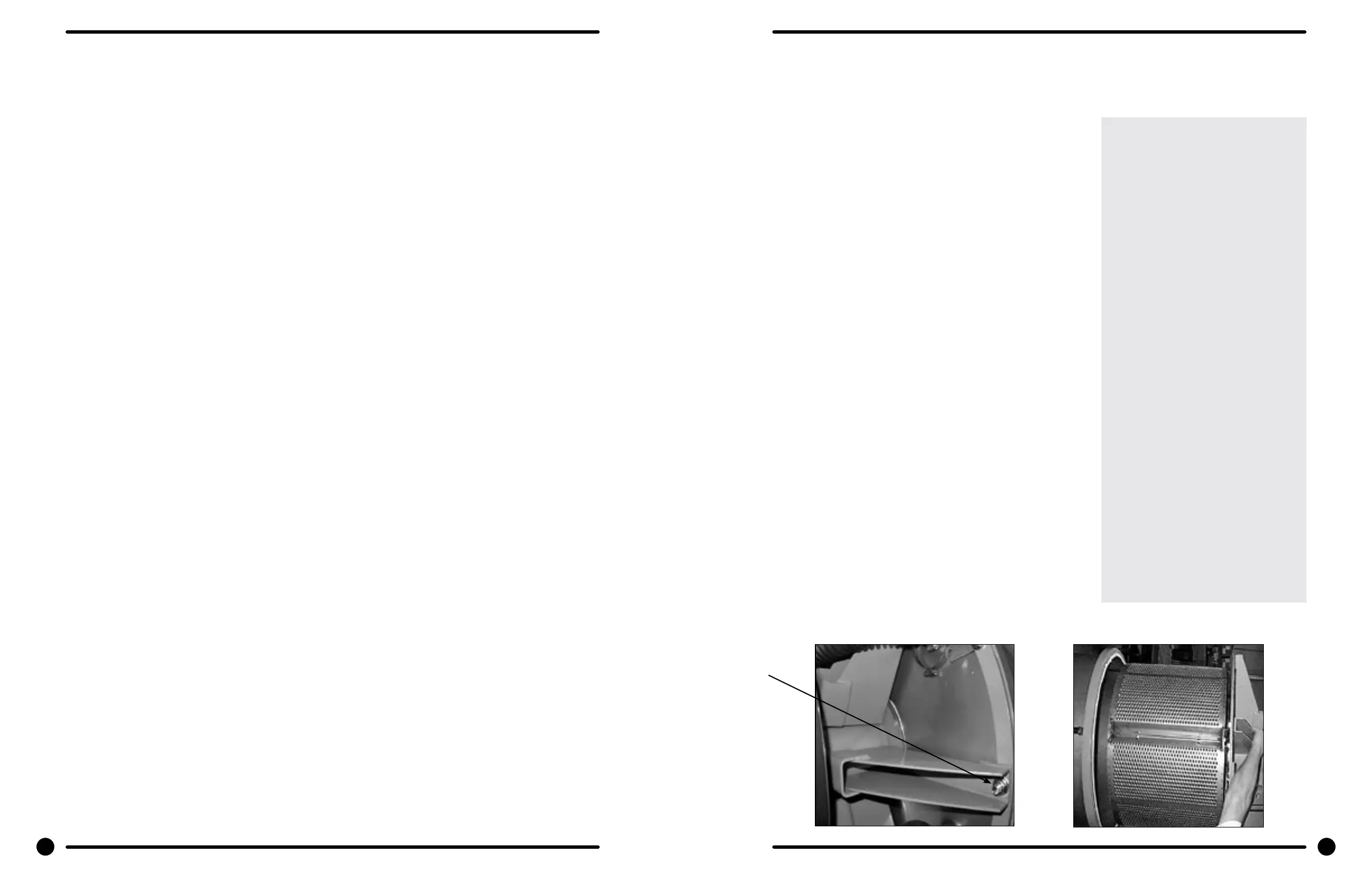

assembly later. (see picture)

Step 6: Remove the 12 bolts and nuts from the perimeter of

the tub back clamp ring. (Two of the twelve bolts are

longer and go through the thicker part of the brace

where it connects to the frame.)

Step 7: Remove the 2 bolts that fasten the clamp ring to the

frame.

Step 8: The entire tub back and cylinder assembly may be

lifted out of the tub (it may be necessary to break the

adhesion of the silicone that seals the tub back to the

tub). Blocks should be placed under the edges of the

cylinder before setting it down to prevent damage to

the cylinder ange.

Outer Cabinet Removal

T-400 & T-600

Removal of Cabinet T-400 & T-600

Step 1: The power supply, water hoses, and drain connection must all be disconnected before proceeding

with the disassembly.

Step 2: Now remove the lower service panel and the top panel assembly.

Step 3: Remove the left and right lower front panel screws that retain the panel to the chassis.

Step 3: Remove the bottom row of back panel screws.

Step 4: Remove the loading door.

Step 5: Remove the screws along the bottom of each side panel. When reinstalling these screws do not

overtighten.

Step 6: Remove clamp and soap dispenser hose where it attaches to the tub inlet. Disconnect the door lock

wires from all switches and the door lock gear motor.

Step 7: Disconnect pull rod between gear motor and door lock assembly. Disconnect the wires to the dump

valve at the bottom of the machine.

Step 8: Disconnect the wires to the drive motor from the VFD T1, T2, T3.

Step 9: Remove the clamp and the hose from the vacuum breaker where it connects to the inlet on the back

of the tub.

Step 10: Remove the pressure switch hose from the bottom of the switch.

Step 11: It should now be possible for two people to lift the cabinet up and o of the front of the machine and

set it aside.

Outer Tub

Removal

Step 1: The outer tub can easily be removed when the tub back, bearing, and cylinder assembly have been

removed as outlined.

Step 2: At that point only attachments to the chassis are the two front strap mounting bolts.

Reassembly

Step 1: Install outer tub in front strap leaving bolts loose.

Step 2: Install tub back assembly in washer (see Reassembly of Tub Back, Bearing, and Cylinder (basket)

Assembly).

Step 3: With tub tback assembly bolted to washer frame and to the back of the outer tub, tighten front strap

bolts.

50 51

Part # 8533-035-002 4/22 Part # 8533-035-002 4/22

Loading...

Loading...