SmartSource Elite Series - Installation & Operations Guide

May 2019 8227 4907-005 Page 33 of 37

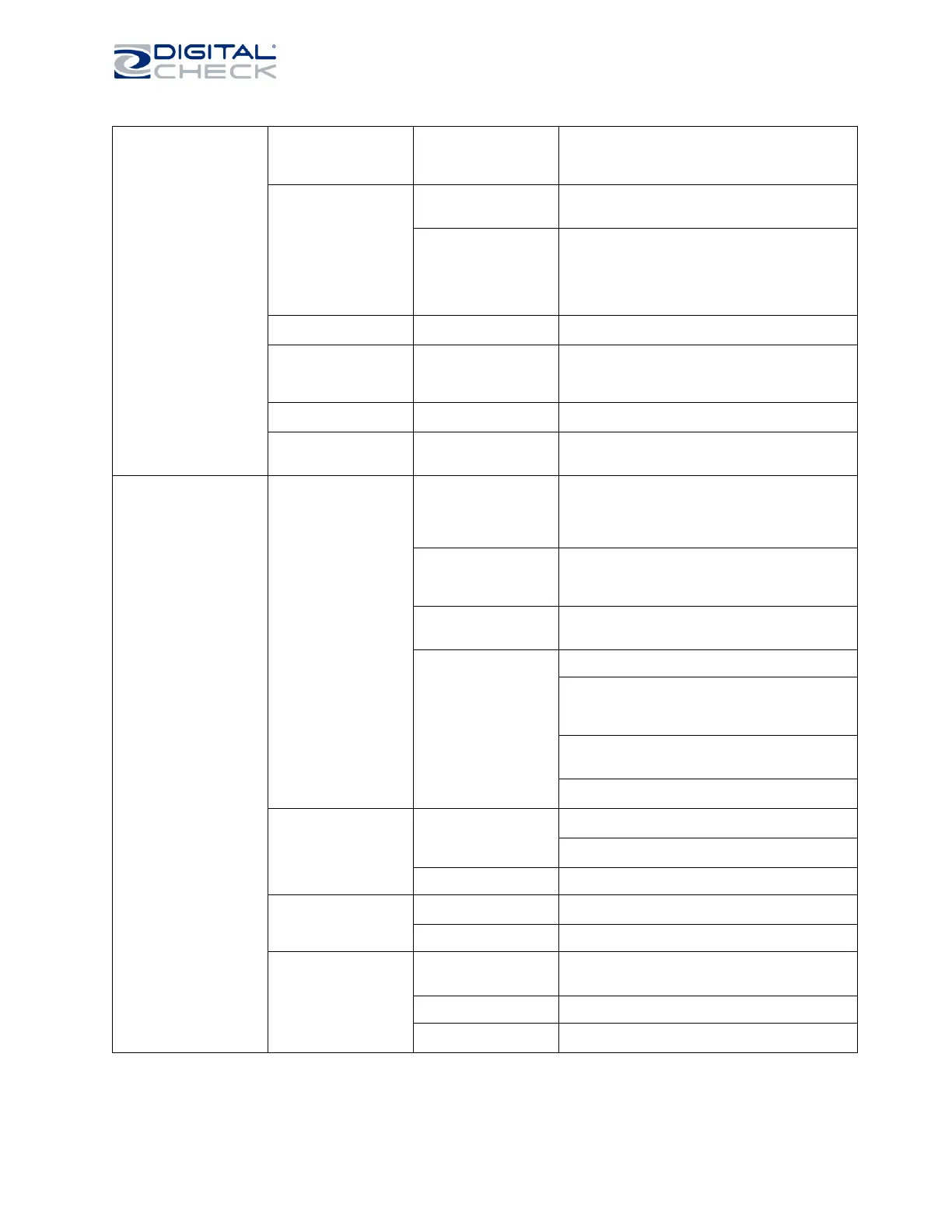

Track stops frequently

with the same error

message

Error message (in

Update Monitor) will

indicate the cause of

the repeated problem

Use error message to identify the appropriate

problem area

Track stops/fails to

start with a ‘document

in track’ message

Document or debris is

stopped in track and

blocking track sensor

Inspect and clear as required.

Several different jams

are “mapped” into this

single message, a

“decoding” effort will

reveal what area of the

track reported the jam

Consult with your IT or application provider to

analyze error codes.

Items do not feed

correctly

See “Feeder” conditions below

Items feed into the

track but then stop

suddenly and have

leading edge damage

Debris/obstruction in

paper path

Examine paper path to locate small bits of paper,

tape, staples, etc. Remove debris gently using the

spatula tool.

Item stops in curved

portion of track

Item is too thick or too

stiff

Card stock, envelopes, carriers will not travel

correctly if they are too thick or too stiff.

False Double

Document stops

Unusual dark marks,

borders, or bands on

document

Try running document upside down (image can be

“flipped” later in process)

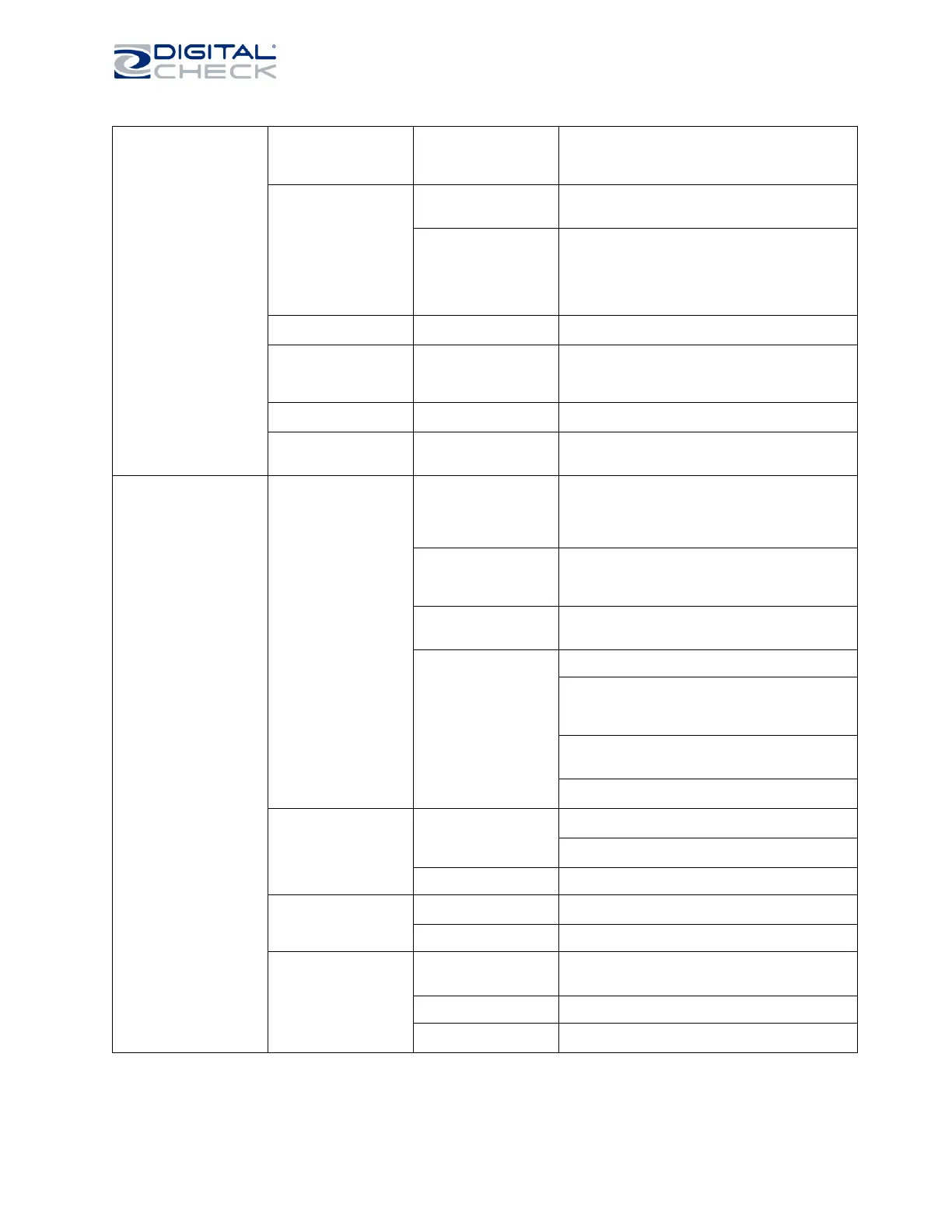

Items do not feed

correctly

Feeder motor runs but

one or both feeder

rollers don’t turn

(possible bad clutch

within the roller)

Interchange the two feeder rollers, replace one or

both if problem follows roller or persists

Feeder motor runs,

and feeder rollers turn

but items will not move

out of the feeder

Feeder roller tires or the documents are worn or

soiled. Clean / replace the tires and retry. Ensure

documents do not have a glossy coating.

Feeder motor runs but

orange document belt

is not moving

Examine belt path to ensure belt has not come off

a roller or is jammed by debris. Return for service

if belt is broken or cannot be moved by hand.

Feeder motor does not

run

Verify no documents or debris in track

Verify Digital Check-branded Endorser Cartridge is

installed. Error messages indicating “Wrong

Cartridge Type” (or similar) are a clue. Unit will not

feed if non-Digital Check cartridge is installed.

Verify endorser cartridge is firmly seated. Unit

won’t feed if cartridge is not making good contact

in its housing.

If problem exists using other applications the unit

requires repair

More than one

document is fed

(doubles, multiple

feeds, “piggy-backs”)

Inadequate work

preparation

Ensure work is properly jogged, aligned, and

loaded correctly in the feeder

Ensure leading edge corners are not bent, curled,

or torn off

Rotate or replace blue separator.

Items skew as they are

fed

Inadequate work

preparation

Ensure work is properly jogged, aligned, and

loaded correctly in the feeder

Rotate or replace blue separator tire

False “Hopper Empty”

messages

Items not properly

loaded in feeder

hopper

Items should be jogged then loaded into feeder

hopper with leading edge of deck touching front

feeder wall

Loading...

Loading...