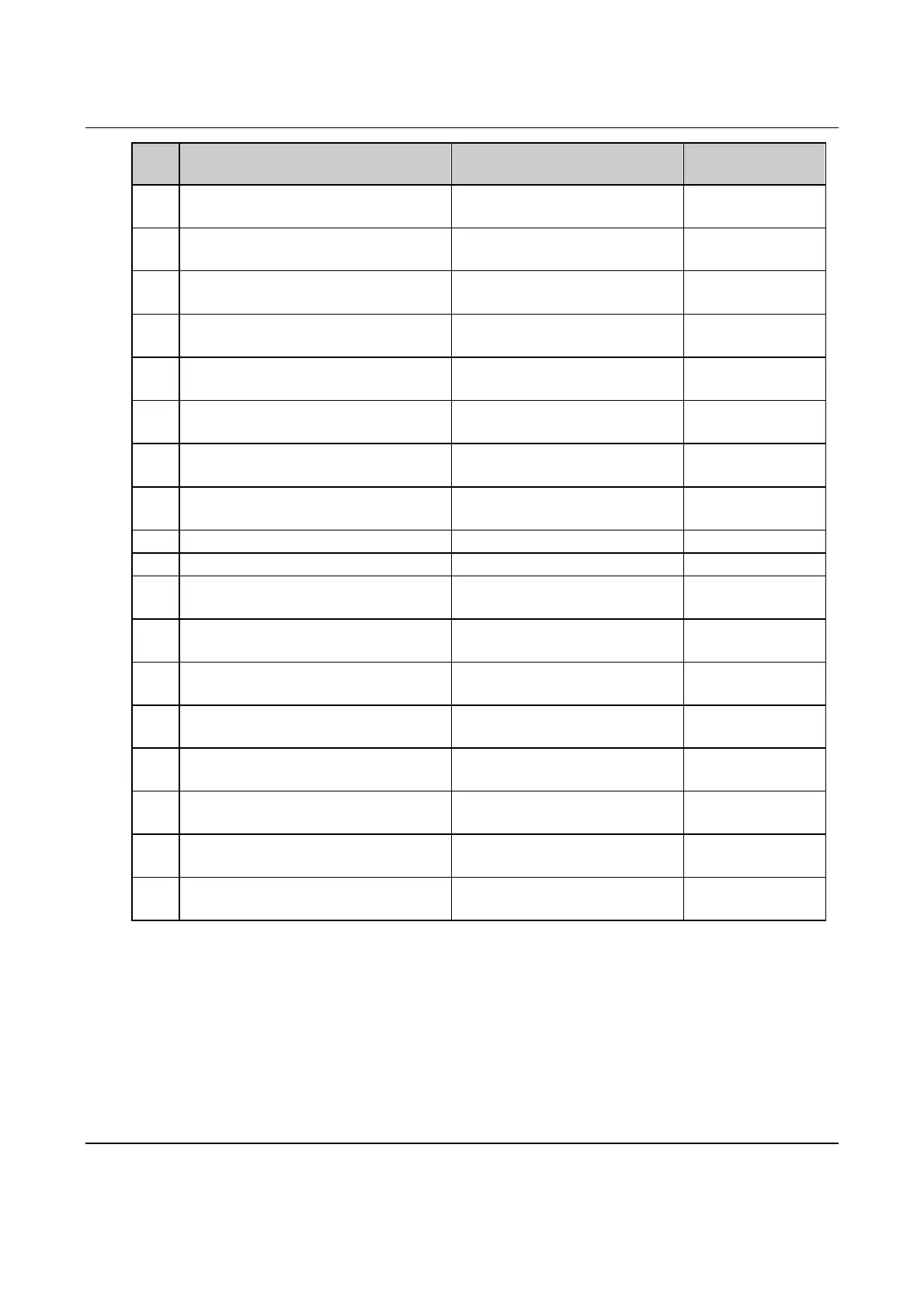

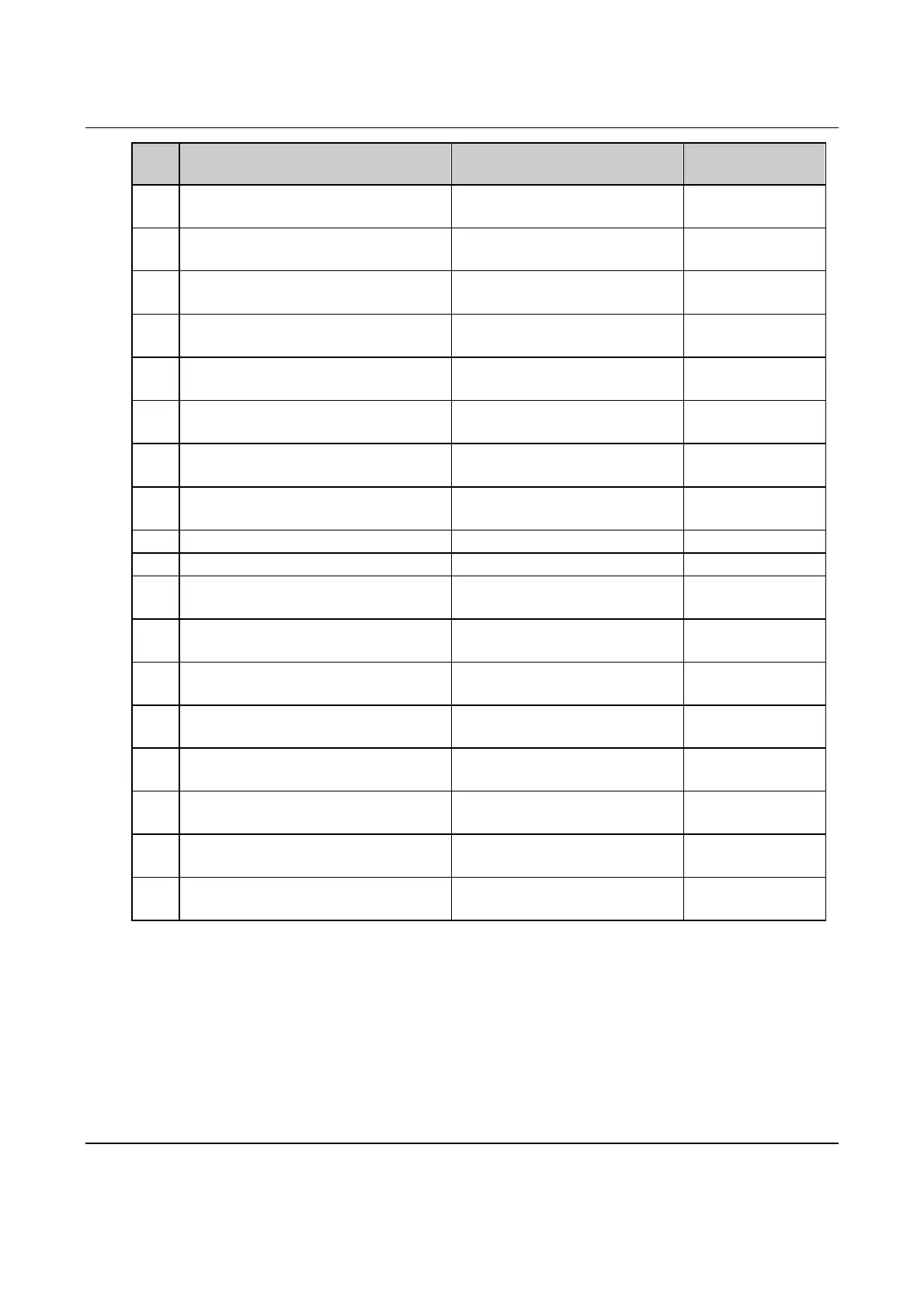

A-13

Rear panel piping and wiring connection ports (Continued)

No. Name

Applicable hose

(Unit: mm)

Connection Port

(*1)

6 Spindle coolant water supply

Braided hose

(9 ID × 15 OD)

Rc1/4

(*2)

7 Spindle coolant water drainage

Braided hose

(12 ID × 18 OD)

Rc1/4

(*2)

8

Wheel coolant/

cleaning water drainage

Duct hose

(76.4 ID × 87 OD)

Flange pipe

OD: 76 mm

(*3)

9

Vacuum unit drain pan drainage

(Standard)

Braided hose

(12 ID × 18 OD)

Rc1/4

(*2, 3)

10 Vacuum unit air exhaust (Standard)

Duct hose

(38 ID × 45.8 OD)

Flange pipe

OD: 38 mm

(*4)

11 Vacuum unit water drainage (Standard)

Duct hose

(76.4 ID × 87 OD)

Flange pipe OD:

76 mm

(*3)

12 Exhaust (Standard)

Duct hose

(88.9 ID × 100.1 OD)

Flange pipe

OD: 89 mm

(*3)

13 Exhaust (Duct unit)

Duct hose

(125.9 ID × 139.3 OD)

Flange pipe OD:

123 mm

(*3)

14 Power supply

(*5)

Cable (AWG8) R8-8

15 Power supply (DTU152)

(*5)

Cable (AWG4) R22-8

16

Refrigerator coolant water supply

(DTU152)

Braided hose

(25 ID × 33 OD)

Rc3/4

(*2)

17

Refrigerator coolant water drainage

(DTU152)

Braided hose

(25 ID × 33 OD)

Rc3/4

(*2)

18

Water temperature control unit

(DTU152) tank water drainage

Braided hose

(25 ID × 33 OD)

Rc3/4

(*2)

19

Water temperature control unit

(DTU152) drain pan drainage

Braided hose

(15 ID × 22 OD)

Rc1/2

(*2)

20

Spindle coolant supply unit tank water

supply

Braided hose

(15 ID × 22 OD)

Rp3/8

(*2)

21

Spindle coolant supply unit tank

overflow water drainage

Braided hose

(15 ID × 22 OD)

Rp3/8

(*2)

22

Spindle coolant supply unit tank water

drainage

Braided hose

(15 ID × 22 OD)

Rp3/8

(*2)

23

Spindle coolant supply unit drain pan

drainage

Braided hose

(15 ID × 22 OD)

Rp3/8

(*2)

(*1) Diameter of the hose or joint to be furnished by the user.

(*2) Connection port for hard piping to be made by the user.

(*3) Discharges drain water or mist that contains grinding dust or silicon debris.

(*4) Outdoor exhaust type and therefore no silencer is mounted here. A duct hose is not attached as

standard accessory.

(*5) When a power cable is prepared by customers, a cable with the protective conductor (PE wire) which

has a cross-sectional area of at least 10 mm

2

Cu, or 16 mm

2

Al should be prepared.

The power cable for this machine is prepared as an optional accessory.

Loading...

Loading...