enclosed into rotor to ensure the sample does not leak in centrifugal process. If rotor lid is not available, the

rotor would be no bio-sealing function. The rotors can be used as follows:

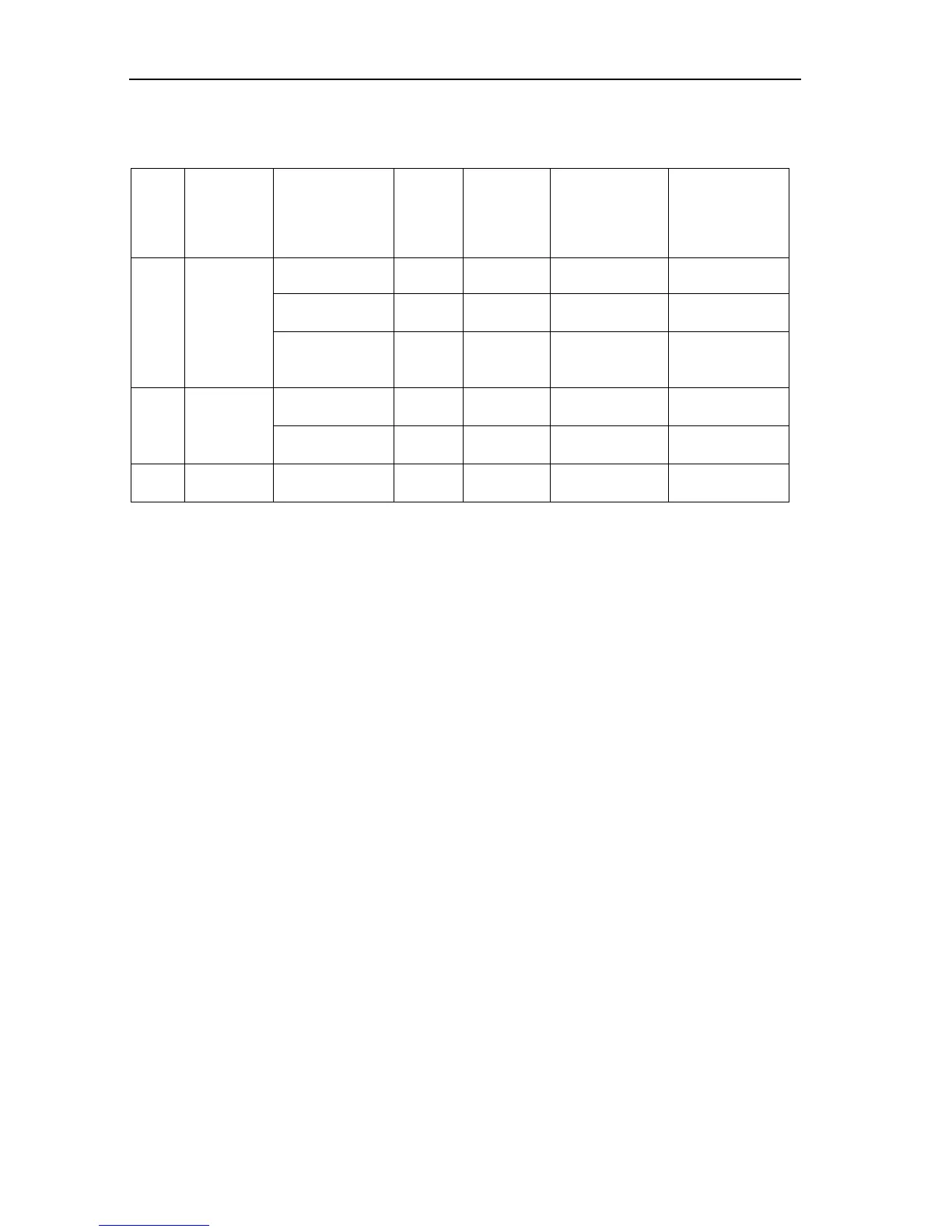

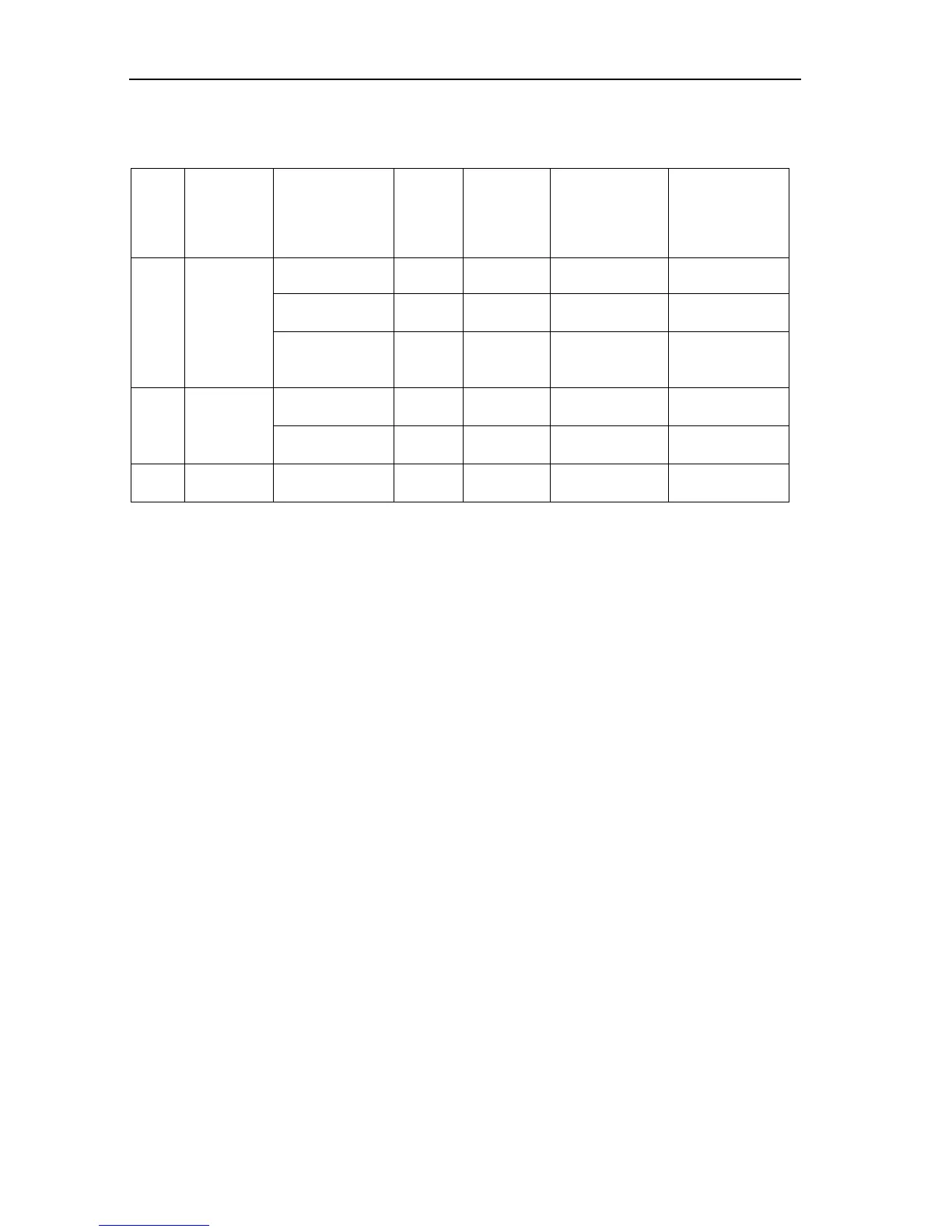

Table 11.1 Rotors and adapters

11.1.3 Notice

(1) The centrifuge rotor can separate sample which density lower than 2.0g/ml, if the samples density is

over 2.0g/ml, please calculate allowable speed depending on the following formula.

Allow Speed (rpm)= Maximum speed

×

(2.0(g/ml)/Sample density (g/ml))

1/2

(2)To prevent corrosion, remove the rotor from rotor chamber if do not use for a lone term, then detach

the rotor lid and upside the rotor down to dry the tube holes.

(3)If some samples leaked in the rotor hole, wash the hole with water, apply a thin coat of silicon grease

on the rotor surface after drying.

(4)It is necessary for a regular maintenance for rotor, recommend to clean it each 3 months to keep

cleaning of tube hole and shaft hole, and then apply a thin coat of silicon grease on it.

11.1.4 Autoclaving

The rotor is manufactured in high-strength aluminum alloy material and can be autoclaved:

121

℃

(1.0kg/cm2),

20 minutes.

11.1.5 Bio-safe seal ring

The rotor is sealed by bio-safe structures, achieved using three high-temperature rubber seal rings. The seal

rings may fall off or aging after several autoclaving, need to be replaced or re-installed. The replacement

methods please refer to the section 9.3.

Loading...

Loading...