movement of the tool in

balance during the

tensioning process. Lift the

rocker lever to stop working

when an emergency stop is

required during the

tensioning process.

Therefore, do not block the

movement direction of the

strapping tool.

d.Weld and cut off the strap:

Weld and cut off the strap to

finish the strapping operation

by referring to the Method for

Basic Settings.

The purple indicator light will

be on during the welding

e.Remove the machine and

complete the operation:

After the welding is finished,

the buzzer rings for 3 seconds

and stops, indicating that the

strap welding and cutting work

is completed. At this time, you

can remove the machine by

lifting the rocker lever and

moving the tool rightward and

wait for a next operation.

Remarks: 1. In the Automatic(AUT) Mode, only Steps a, b, c, e are

required.

2. Remove the battery and then install it again, if the machine

fails to work normally due to misoperation or other reasons.

3. When the strap is stuck by the machine, the battery must be

pulled out first, then cut off the strap, remove the panel screw,

and then remove the strap.

4.The tension protection function will start by pressing the

button Tensioning continuously for 8 times, and at this time, the

protection function can be cancelled by lifting the rocker lever

once.

5. Note: If the rocker lever is lifted immediately after welding,

the machine will give rapid sound alarms for 5 seconds due to a

5.2.4 Operation Methods for Three Modes

Manual Mode (MAN): Long press the button Tensioning until the set tension grade is

reached, and the machine will stop automatically. Then press the

button Welding, and strap welding and cutting will be finished after

three short sounds of "Beep", and at this time, hold the rocker lever to

retract the strap and remove the

Semi-Automatic(SEM): Long press the button Tensioning until the set tension grade is

reached, and the machine will automatically weld and cut off the

strap. The strap welding will be finished after three short sounds of

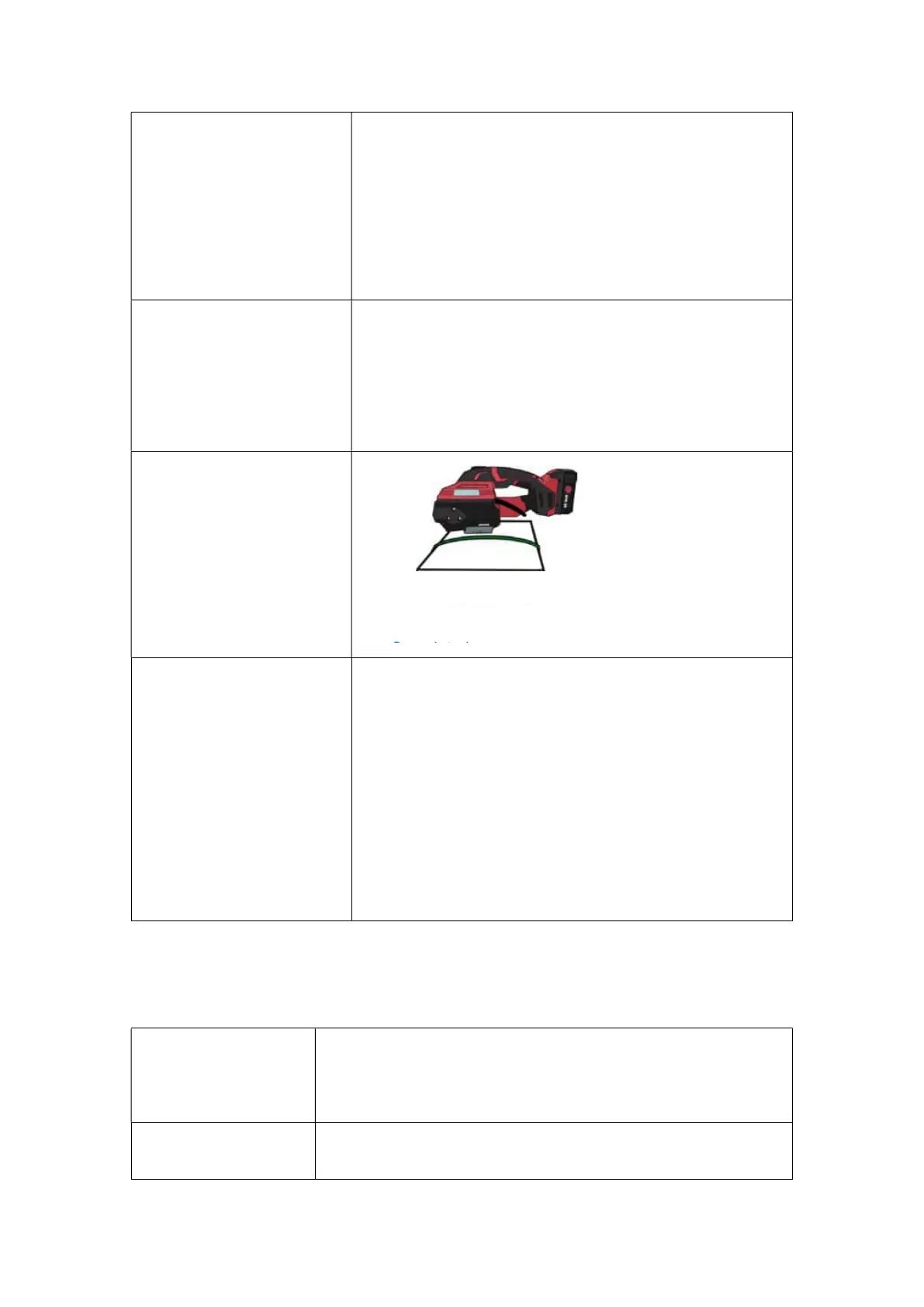

Strap Welding & Cutting

Loading...

Loading...