2. The machine can be wakened up by pressing the button Tensioning,

and then enter the state of step a;

3. Strapping (the same as step b).

e.Red light flashing It indicates the power is low, so replace the battery or remove the battery

5.3 Strapping Effect and Adjustment

5.3.1 Strap Welding Effect Judgment

It is necessary to control the welding effects after each strapping, which can be judged by visual

inspection.

There are the following three situations, as shown in the figure:

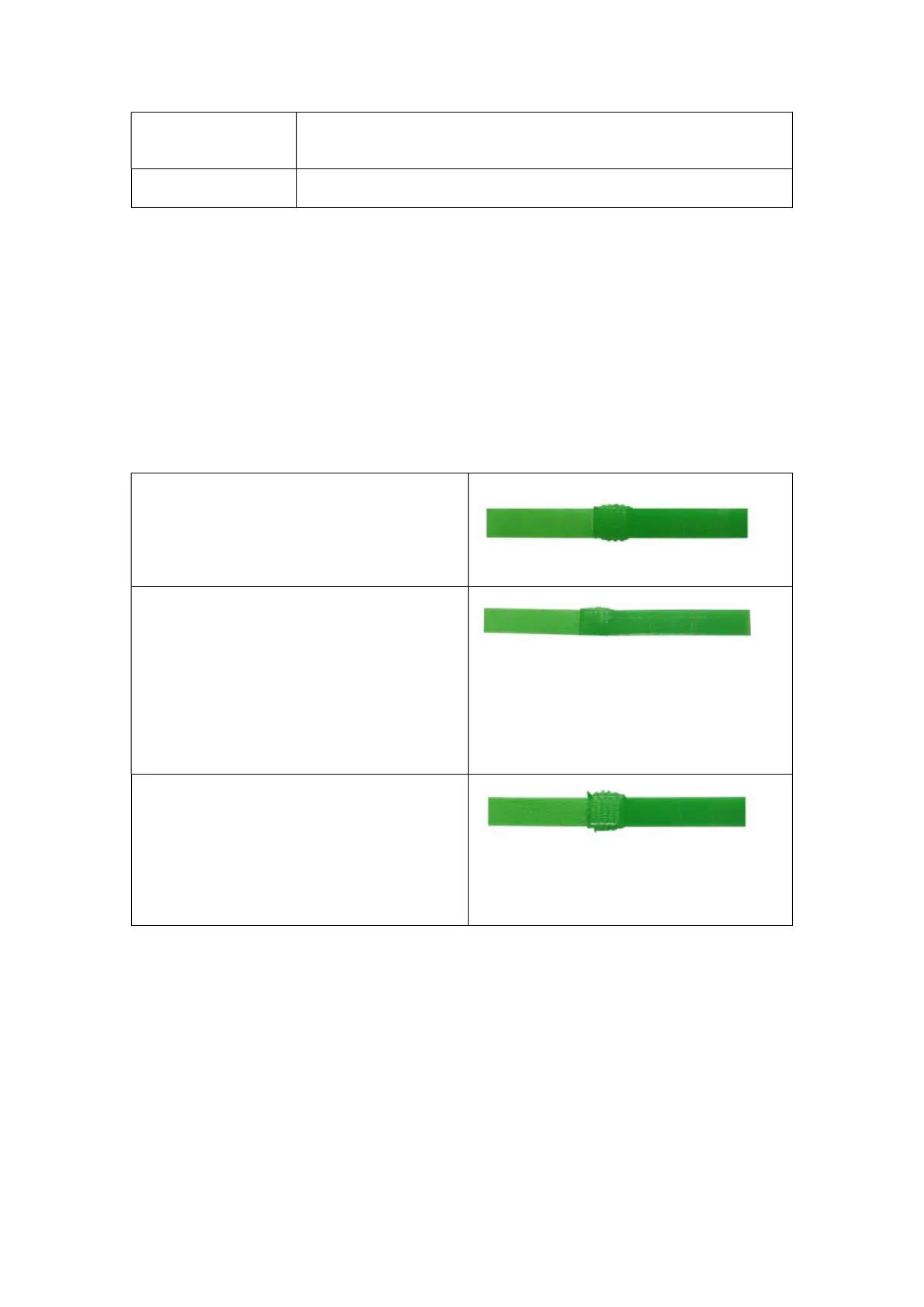

Welding time & effect perfect:

The whole width of the strap is welded fully in

the strap welding area, and the welding length is

about 19mm. A little molten material is forced

out on both sides, indicating that the welding

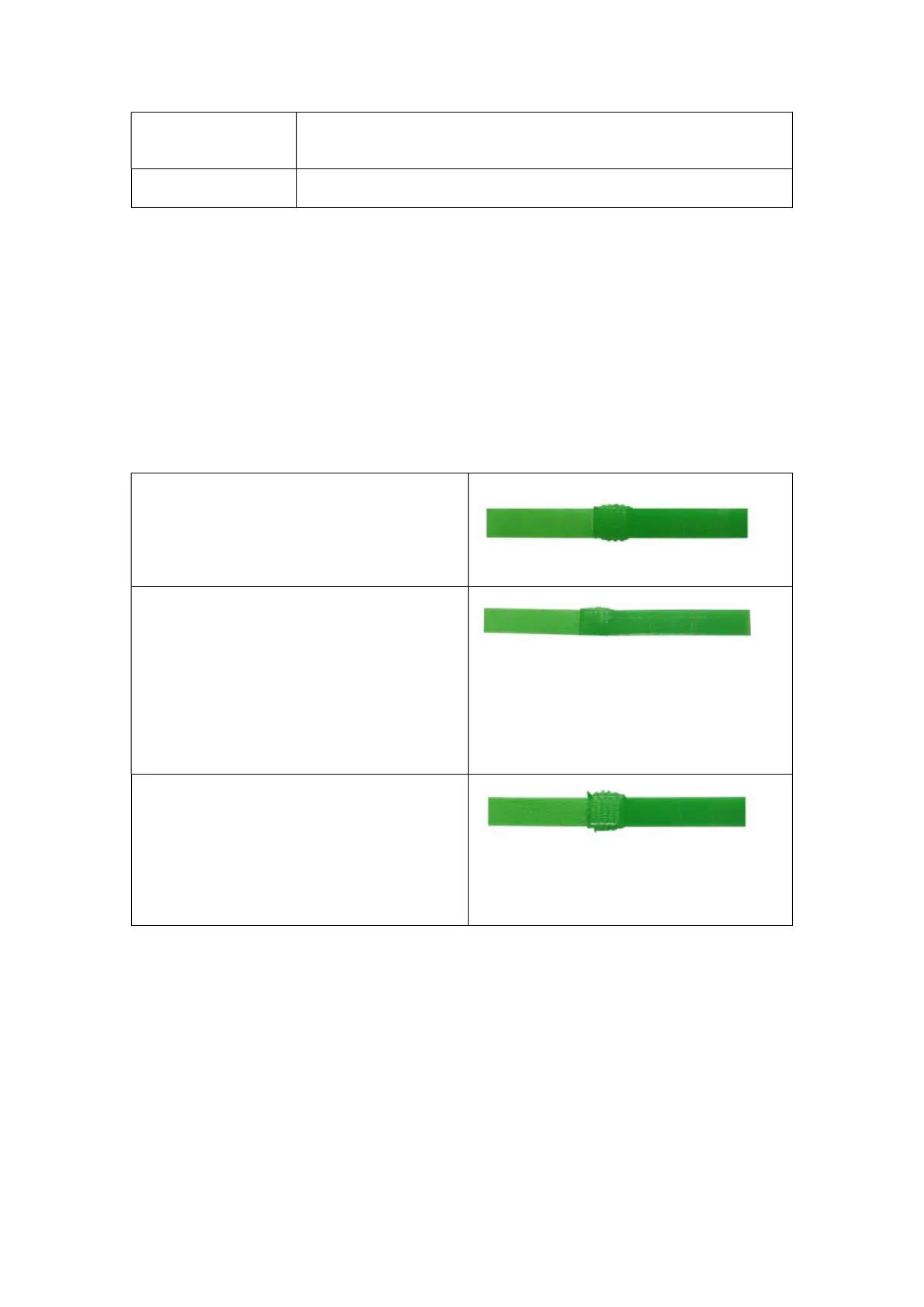

Welding time too short:

In the strap welding area, there is no molten

material forced out on both sides or only a little

forced out on one side, and the whole strap

width is not welded, all of which indicates

insufficient welding time and insufficient

welding.

!Warning: The strap with insufficient welding

must be cut off, adjust the welding time and

Welding time too long:

If the welding time is too long, it will lead to

strap overheating. Excessive molten material

forced out on both sides of the strap in the strap

welding area indicates welding time too long.

!Warning: The strap with excessive welding

must be cut off, adjust the welding time and

5.3.2 Appropriate Parameter Adjustment

When the strapping effect is too loose or too tensioned, and the welding time is not appropriate,

please adjust the parameters following the setting method to keep the strapping effect in the best

condition. The tool cannot be used grudgingly, especially when the welding time deviation is too

large, which may cause strap off, causing harm to the operator or products.

Machine adjustment method for different material straps(PP/PET) and different strap width:

Loading...

Loading...