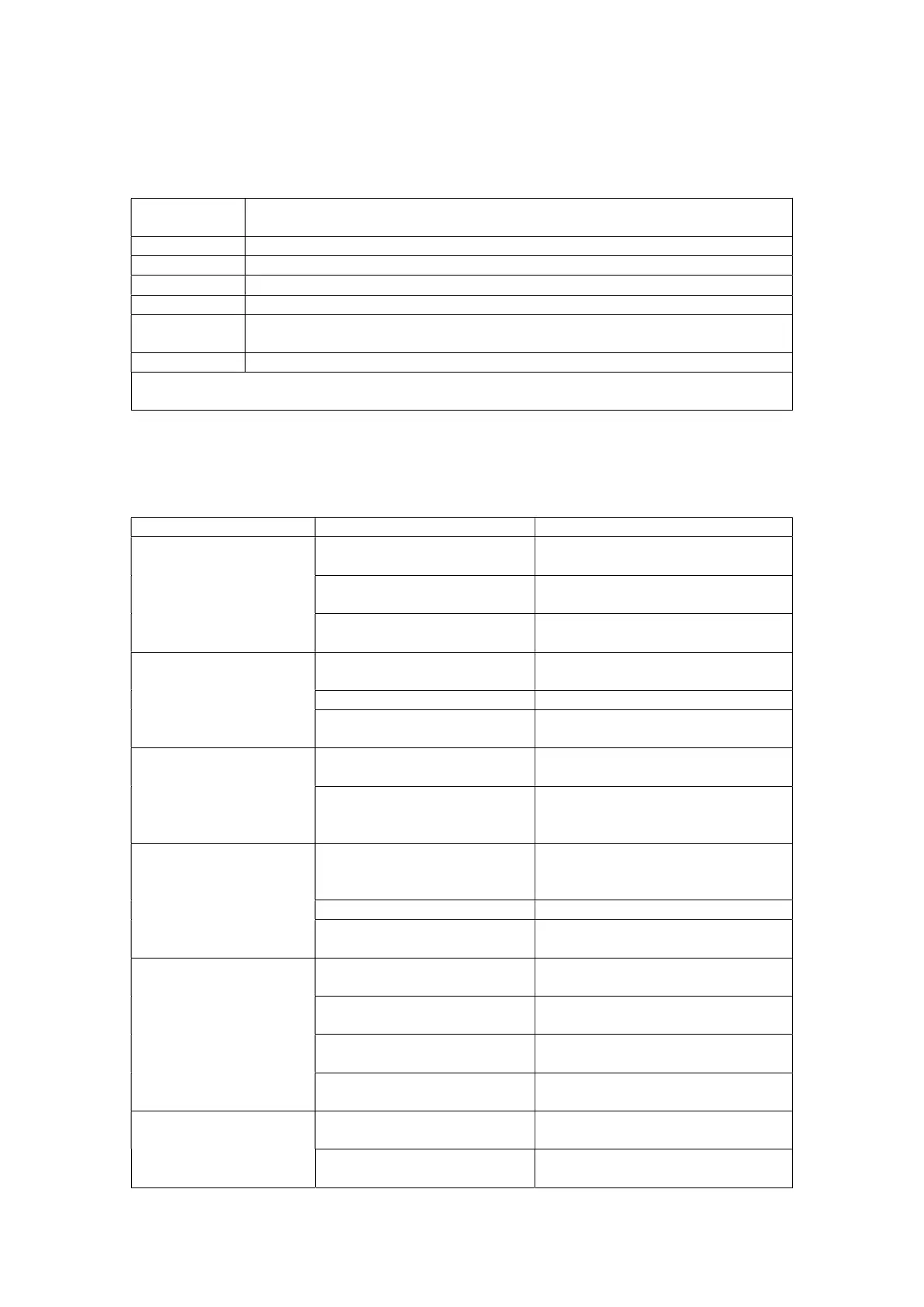

7.1 Machine Fault Code Description

E0.2 tension motor timeout fault (tension function not completed after more than 10

short circuit fault of tension motor

Tension motor Hall abnormal/abnormal current induction of tension motor

short circuit fault of welding mot

Welding motor Hall abnormal/abnormal current induction of welding motor

E1.0 A motor is still outputting torque when the speed of the motor is 0 rpm/motor

In case of any of the above faults, you can remove it by pressing any button and enter the standby

mode. If it can't return to normal, please c

ontact the supplier for solutions.

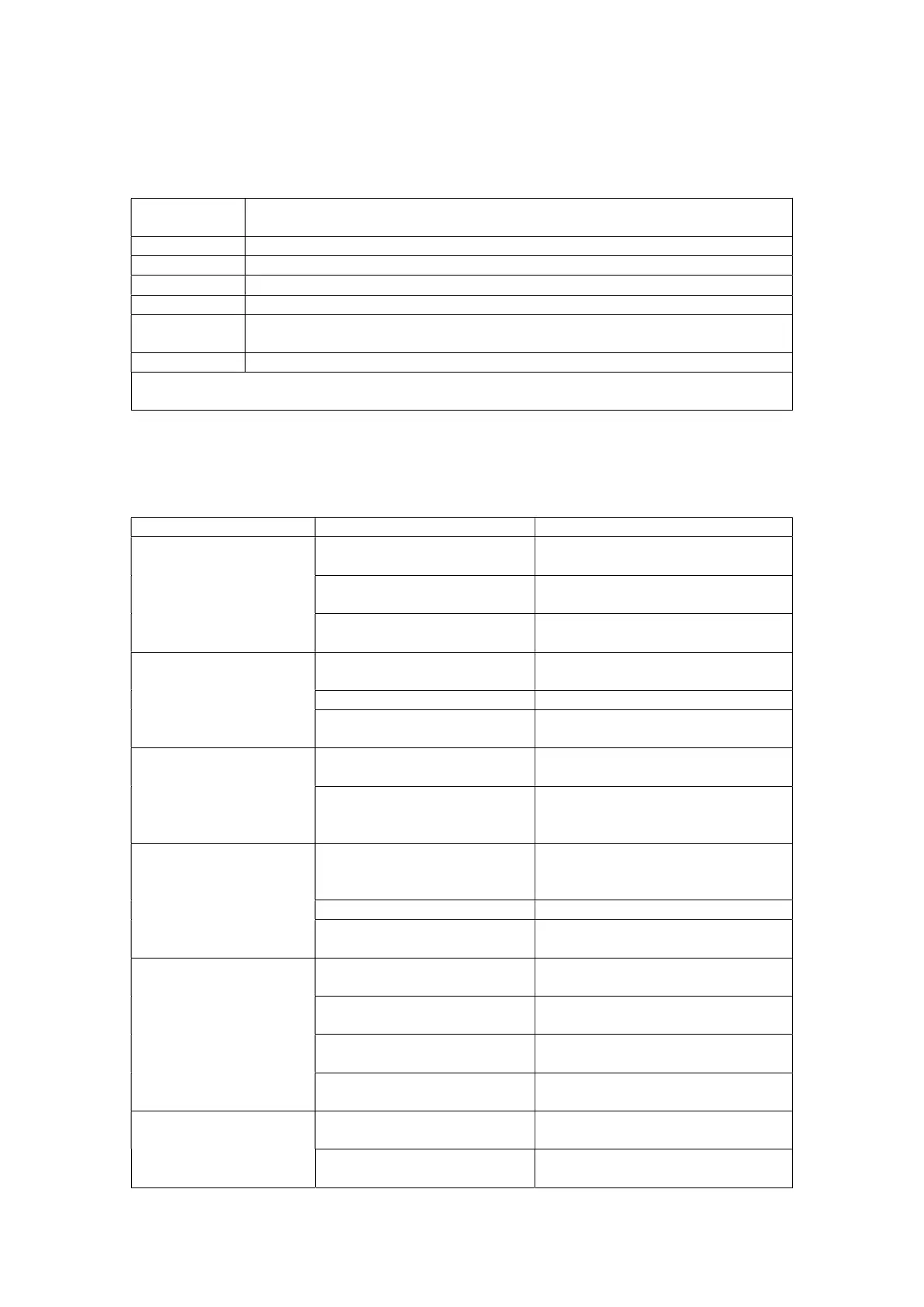

7.2 Common Faults and Troubleshooting

Abnormal Situation Possible Causes Solution

The machine doesn't

work

The battery is not installed

properly or short of power

Reinstall the battery or charge it

Tension micro switch wire

Re-weld/re-connect the wires

Failure of tension micro

Replace the strap tension micro

The strap can not be

retracted or pulled

Short of power possible Check the battery power, if it is low,

charge it and then use it

Soft mode(L) Switch the mode to be Normal

The machine slides

forward when

tensioning strap

Strap debris accumulated on

Remove debris with a drill pin in the

The anti-sliding toothed plate

Replace the anti-sliding toothed

plate

Tension motor idles

Strap debris accumulated in

the surface toothed grooves of

Remove debris with a drill pin in the

tool kit

The strap too thin Add an appropriate gasket under the

Incomplete welding

Welding time too long or too

Make adjustments by referring to

5.3 Strapping Effect and Adjustment

Strap debris accumulated on

Remove debris with a drill pin in the

The friction toothed plate

Replace the friction toothed plate

Strap width not adjusted

Adjust the strap width limit

Operation completed

but strap broken

Welding time too long or too

Make adjustments by referring to

5.3 Strapping Effect and Adjustment

The items to be strapped

Check if the cooling time is too

Loading...

Loading...