DV11

Operation and Maintenance

97

Engine Reassembly

Printed in Mar. 2005 PS-MMA0608-E1A

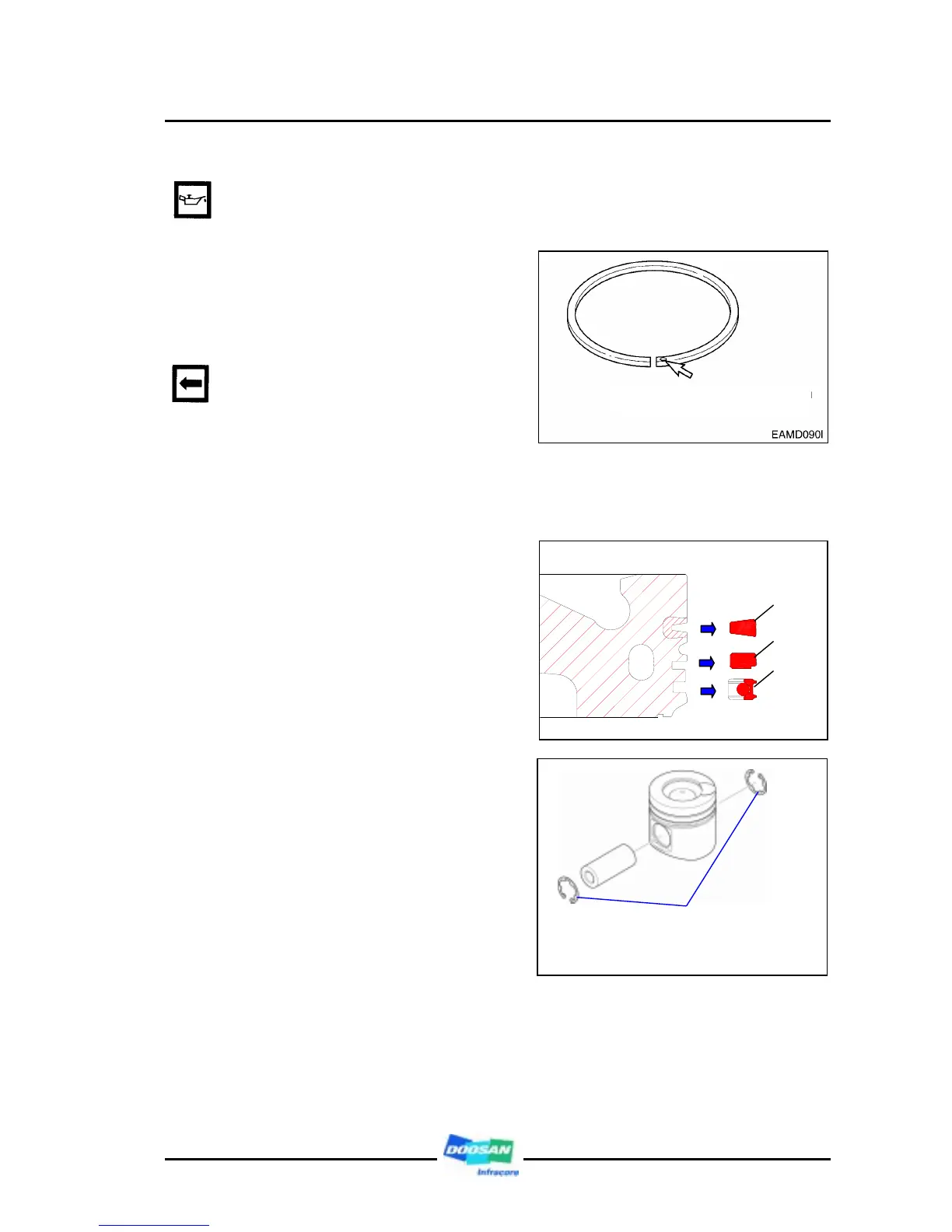

z Coat the pistons and connecting

rod bearings sufficiently with clean

engine oil.

z By means of a special tool, insert

the piston rings and adjust the

angles between the ring gaps at

120°.

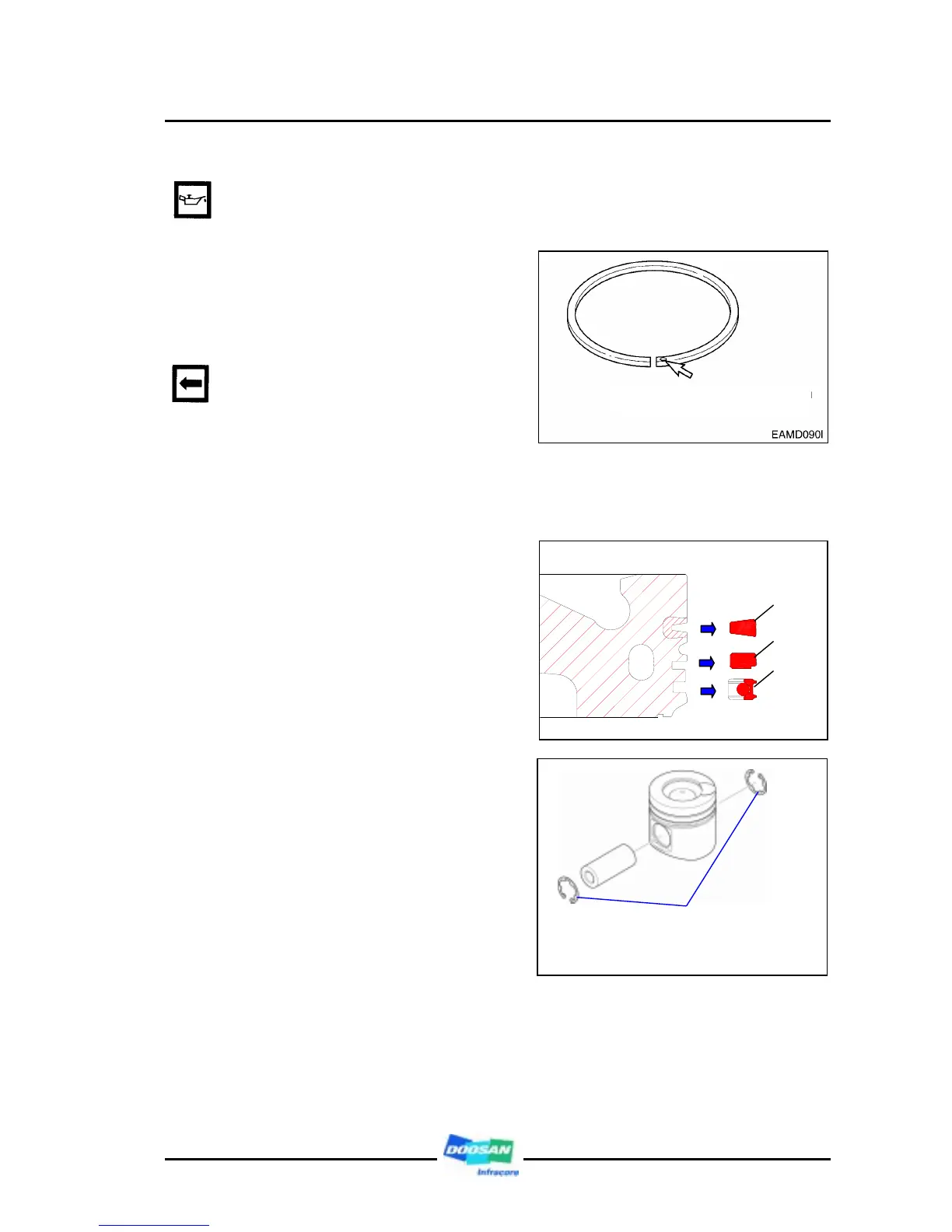

z Identify the mark "Y" or "TOP" on

the ring end to prevent the top and

bottom of the piston ring from

being interchanged and make the

marked portion face upward.

(The surface marked as “Y” or

“TOP” is upper surface.)

z Push in the piston with hands or

wooden bar into cylinder. (Be

careful for piston and rings not be

damaged.

z Pushing the piston down, rotate the

crankshaft about 180° and fit the

bearing cap to the connecting rod.

z Coat the tap parts of connecting

rod bolts and their seats with

engine oil, and after engaging 2~

3 threads of bolts primarily rind

then tighten them to the specified

torque. (10 kg.m + 90°

+10°

)

“Y” or “TOP”

Top ring

2nd ring

Oil ring

CAUTION:

Direction of snap ring is

assembling to be positioned the

opposite side

Loading...

Loading...