DV11

Operation and Maintenance

144

Common Rail Fuel-injection System

Printed in Mar. 2005 PS-MMA0608-E1A

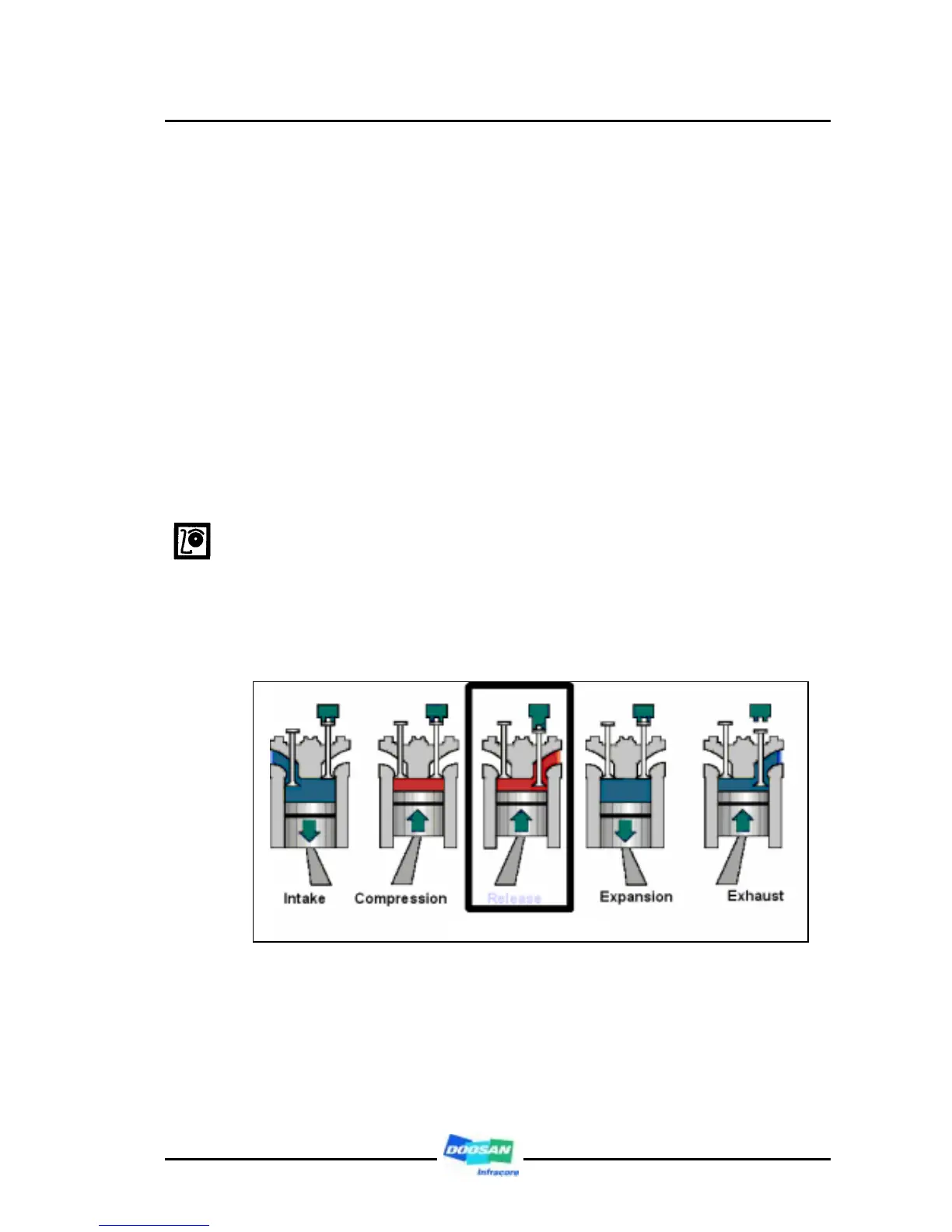

z The exhaust rocker arm moves up (as in normal injector cycle), forcing the master

piston upward and creating a high pressure oil flow (J) to the slave piston of the

braking cylinder. The check ball valve (K) in the control valve traps high pressure

oil in the master/slave piston system.

z Under the influence of the high pressure oil flow, the slave piston moves down,

momentarily opening the exhaust valves at a pre-determined amount of slave

stroke. The adjusting screw (L) uncovers a passageway in the slave piston, thus

allowing oil to flow back to the underside of the control valve, where it is stored for

the next cycle. Prior to top dead center position, the exhaust valve is forced open,

releasing the compressed cylinder air to the exhaust manifold.

z Compressed air escapes into the atmosphere, completing a compression braking

cycle.

NOTE:

Never remove any engine brake component with engine running. Personal injury

may result.

z Engine Brake is a relatively trouble free device. However, inspections and routine

maintenance are necessary to assure proper operation.

3.6.3. Engine brake disassemble and valve adjustment

z Clean engine thoroughly. Remove all accessory components required to remove

cylinder head covers. Set entire overhead as with no brake, refer to engine

manual procedures. (intake valve and exhaust valve)

Engine brake operation

Loading...

Loading...