DV11

Operation and Maintenance

50

Technical Information

Printed in Mar. 2005 PS-MMA0608-E1A

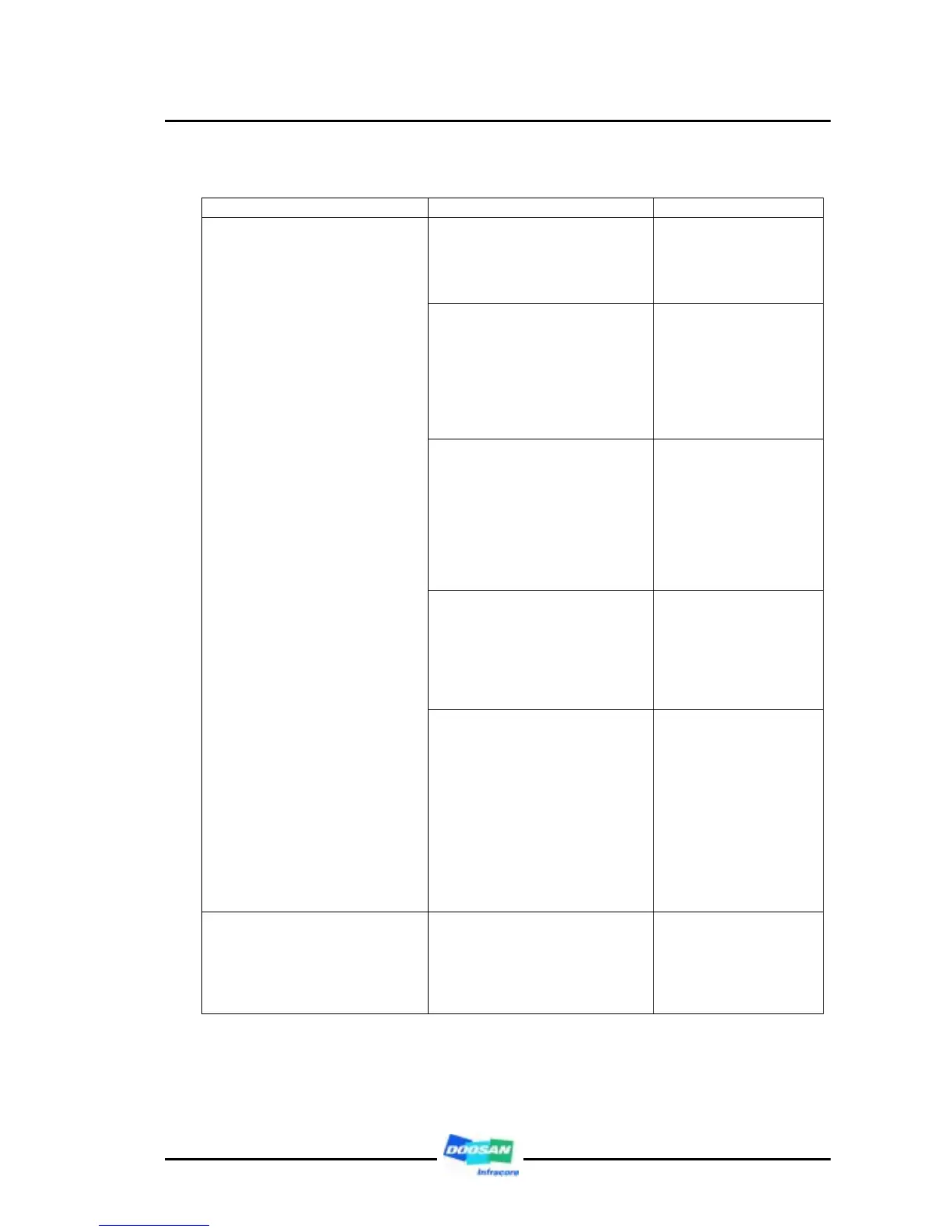

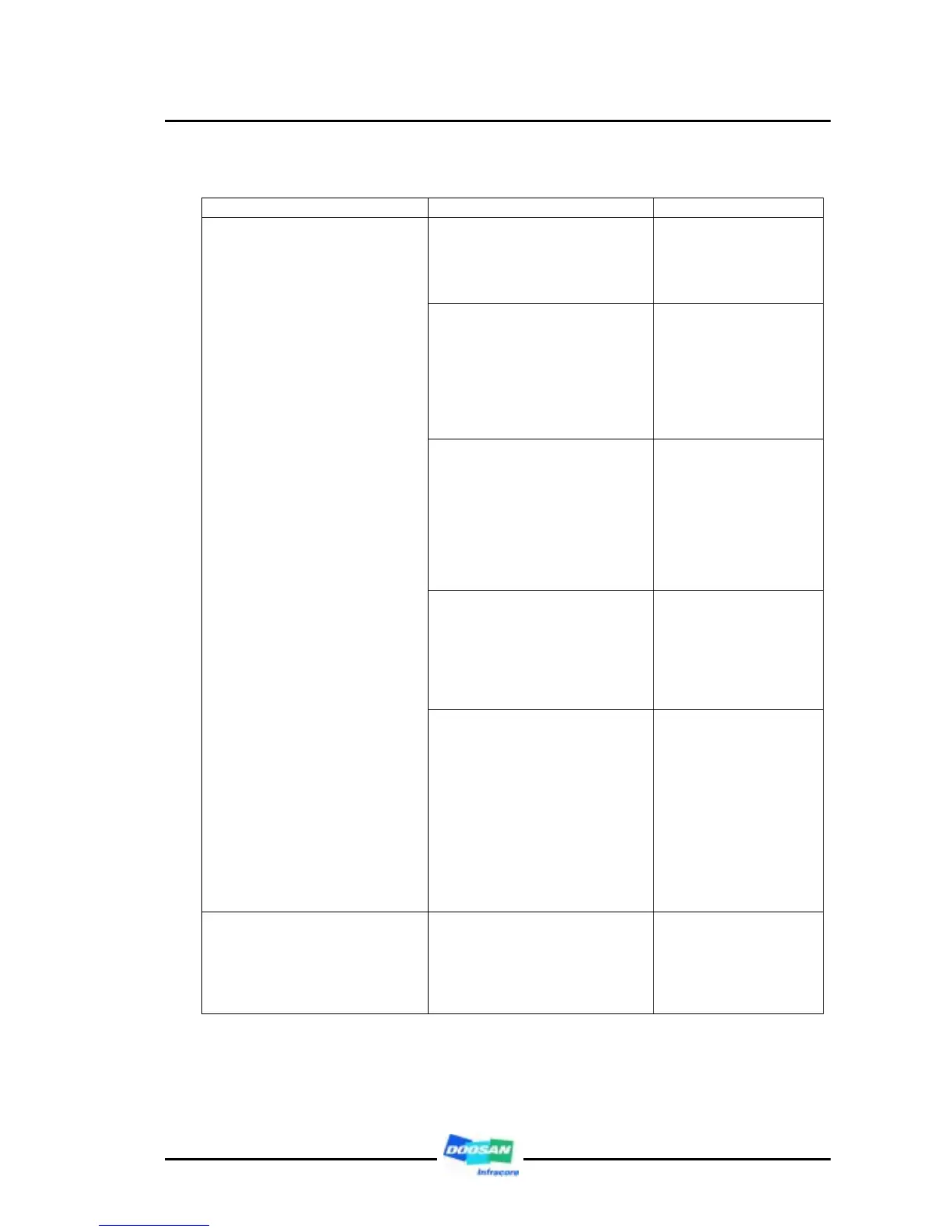

Condition Causes Remedies

5) Engine noisy

For noises arise compositely

such as rotating parts, lapping

parts etc., there is necessity to

search the cause of noises

accurately.

z As the wear of bearing or

crankshaft progress, the oil

clearances increase.

Replace bearing &

grind crankshaft

z Lopsided wear of crankshaft Grind or replace

z Oil supply insufficient due to

oil passage clogging

Clean oil passage

(1) Crankshaft

z Stuck bearing Replace bearing &

grind

z Lopsided wear of con rod

bearing

Replace bearing

z Lopsided wear of crank pin Grind crankshaft

z Connecting rod distortion Repair or replace

z Stuck bearing Replace &

grind crankshaft

(2) Connecting-rod and

connecting-rod bearing

z Oil supply insufficiency as

clogging at oil passage

progresses

Clean oil passage

z Piston clearance increase

as the wear of piston and

piston ring progresses

Replace piston &

piston ring

z Wear of piston or piston pin Replace

z Piston stuck Replace piston

z Piston insertion poor Replace piston

(3) Piston, piston pin &

piston ring

z Piston ring damaged Replace piston

z Wear of crankshaft, thrust

bearing

Replace thrust bearing

z Camshaft end play

increased

Replace thrust plate

z Idle gear end play increased Replace thrust washer

z Timing gear backlash

excessive

Repair or replace

z Valve clearance excessive Adjust valve clearance

z Abnormal wear of tappet,

cam

Replace tappet, cam

(4) Others

z Turbocharger inner part

damaged

Repair or replace

z Injection timing incorrect Check

6) Fuel consumption

excessive

z Fuel injection amount

excessive

z Tire air pressure incorrect

Use of low speed gear is

too frequent

Adjust

Loading...

Loading...