26/40 27/40

Status indicators (maintenance level 1)

COM 2

ADD

COM 1

RT

AL

SD

24 V

M1

Ventilation relation LST

(DIP S2.1 ON/OFF)

Not assigned

V

entilation relation LST

(DIP

S2.2 ON/OFF)

Ventilation duration LST

(DIP S2.3 ON/OFF)

V

entilation duration LST

(DIP

S2.4 ON/OFF)

Ventilation intervall LST

(DIP S2.5 ON/OFF)

V

entilation intervall LST

(DIP

S2.6 ON/OFF)

Not assigned

Not assigned

Not assigned

Not assigned

Not assigned

LST-CO2 logged in

Actuation counter M1

(flashing 5th digit)

Actuation counter M1

(flashing 4th digit)

Maintenance level ON

(Flashing 1x Level 1)

(Flashing 2x Level 2)

Function test - Ventilation elements JK-180 / JK-190

1. Check ventilation element louvres have closed and are airtight (visual

inspection). Replace the entire ventilation element if seals are severely

damaged and can no longer guarantee the ventilation element is airtight

when closed.

It is not possible to replace the louvres’ rubber seals.

2. JK-180 / JK-190 ventilation element drives have been designed for a

minimum of 60,000 “OPEN/CLOSED” cycles.

Once this number of cycles has been exceeded, it may be possible that the

return spring or mechanical drive system fails.

In this case, replace the return spring motor!

Read number of cycles (Maintenance level 1 status indicator, "actuation

counter M1" LEDs). Enter number of cycles in maintenance protocol. It is

not possible to reset the counter to zero.

If the motor is replaced, write down the counter figure in the maintenance

manual upon commissioning. Correctly document replacement.

Example: Red LED (N) flashes for 5-digit figure (e.g. 2x = 20,000)

Yellow LED (O) flashes for 4-digit figure (e.g. 7x = 7,000)

The number of actuations is 27,000.

JK-190

JK-180

Maintenance and cleaning

Once a year by a specialist company, who is authorized by the appliance manufacturer.

Renew test badge, keep log book.

Inspection and maintenance has to be carried out according to D+H maintenance notes.

Only original D+H spare parts may be used. Repair is to be carried out exclusively by D+H.

Maintenance work is only allowed when the device is in a de-energized condition!

Wipe away debris or contamination with a dry, soft cloth.

Do not use cleaning agents or solvents.

Preparation:

- Use personal protection equipment.

- Inspect place of use.

- Inform person responsible for the building about maintenance work.

- If the system has been linked to an on-site fire alarm system, have the corresponding fire alarm system

strand deactivated.

- Attach information signs to each shaft door of the lift.

Carry out the following checks:

- Visual inspection for damage, tightness and debris.

- Check unobstructed distance in shaft between lift components and ventilation element as per EN 81-20.

- Check protected areas between car and ventilation element as per EN 81-20.

- Function test of the system components.

- Check all relevant power supply units.

- Logging of proper maintenance execution and labelling according to specifications.

Fault test of the components:

- Pull out all components connected via RJ45 plugs one after the other.

- A fault, possibly with an alarm, is immediately indicated on the RJ45 socket LEDs of the central unit and

on the smoke extraction button (if present).

- Reconnect the plug. The fault disappears. If necessary, reset an alarm with the reset button.

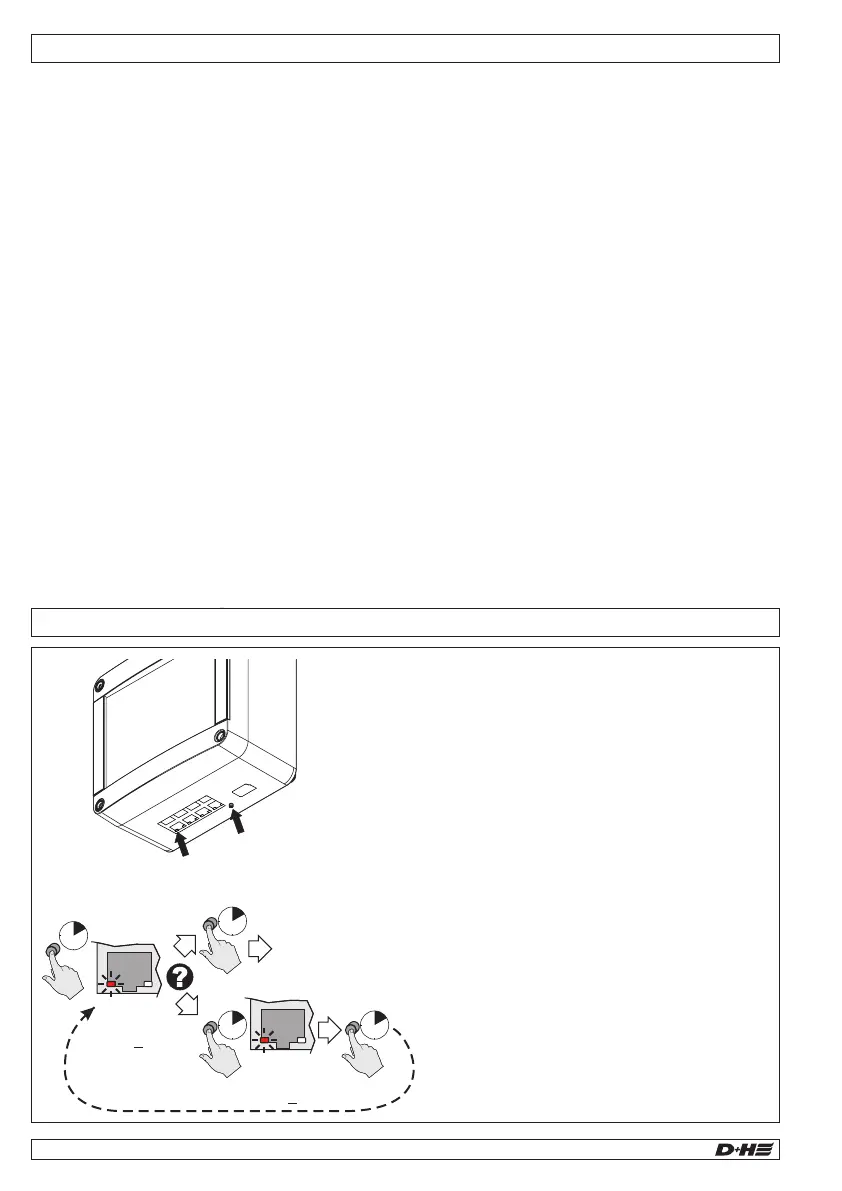

CPL-B

LED „RM“

Reset Button

1x

Maintenance

level 1

SD

2x

Maintenance

level 2

SD

Normal operation -

Maintenance level

deactivated

~

3

Sec.

~

1

Sec.

~

1

Sec.

~

3

Sec.

Maintenance mode / Alarm Reset - CPL-B

1. Press the Reset button for 3 seconds

(maintenance level 1 / LED "SD" flashes 1x/sec.)

System runs LED test, all LEDs at the ports

light up for approximately 4 seconds.

Any active alarms are reset.

The ventilation element opens.

Check the number of ventilation element

cycles "M1" (see next page).

2. Either press the reset button for 1 second

(maintenance mode is deactivated).

or

Press the reset button again for 3 seconds

(maintenance level 2 / LED "SD" flashes

2x/sec). The ventilation element closes and

remains closed (e.g. blower door test).

3. Press the reset button for 1 second

(maintenance level 1 is activated again).

The ventilation element opens again.

4. Press the reset button again for 1 second

(maintenance mode is deactivated).

The central unit is back in normal operating

mode.

99.829.07 1.2/06/2399.829.07 1.2/06/23

AIO Basic AIO Basic

English

English

Following tests must be carried out in the course of

maintenance:

- Outside examination / inspection of system

components

- Checking of all relevant power supply units

- Functional testing of connected system

components

- Record of competent carrying-out of

maintenance, and designation according to

directions

Examination:

- Check all appliances and cable connections for

outer damage and dirt accumulation.

- Fire detectors, smoke vent buttons, smoke vents

and so on must not be impaired in their function

by goods in storage or structural changings.

Loading...

Loading...