2.8 Thread tension

The interlacing of the threads must lie in the middle of the workpiece.

Thick and hard material requires a tighter thread tension than thin and

soft material.

In case of thin material a too high thread tension can lead to undesired

ruffling and thread breakage.

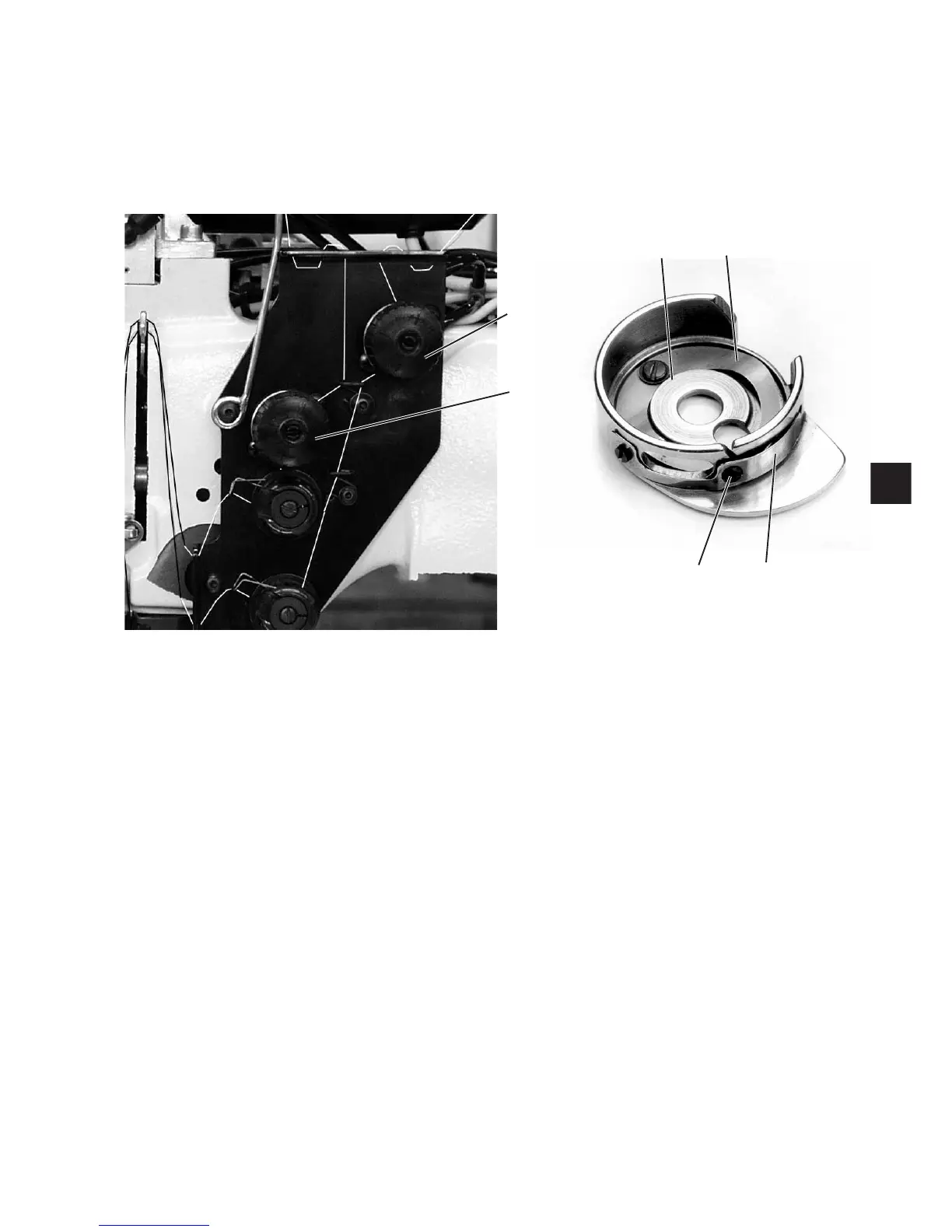

Setting the brake spring 4:

In case of a positioned stop of the machine head the brake spring 4

avoids an after-run of the hook thread bobbin.

–

Set the brake spring 4 by alignment.

The brake power is adjusted correctly when the brake spring 4

projects approx. 1 mm above surface 3.

–

When setting the tension spring 6 the brake power is to be taken

into account.

Setting the tension spring 6:

–

First set only a minimum tension of leaf spring 6 at the adjusting

screw 5.

Increase the hook thread tension: Turn to the right

Reduce the hook thread tension: Turn to the left

–

With the bobbin inserted and the hook thread threaded through the

throat plate a uniform and easy pull-off must be assured.

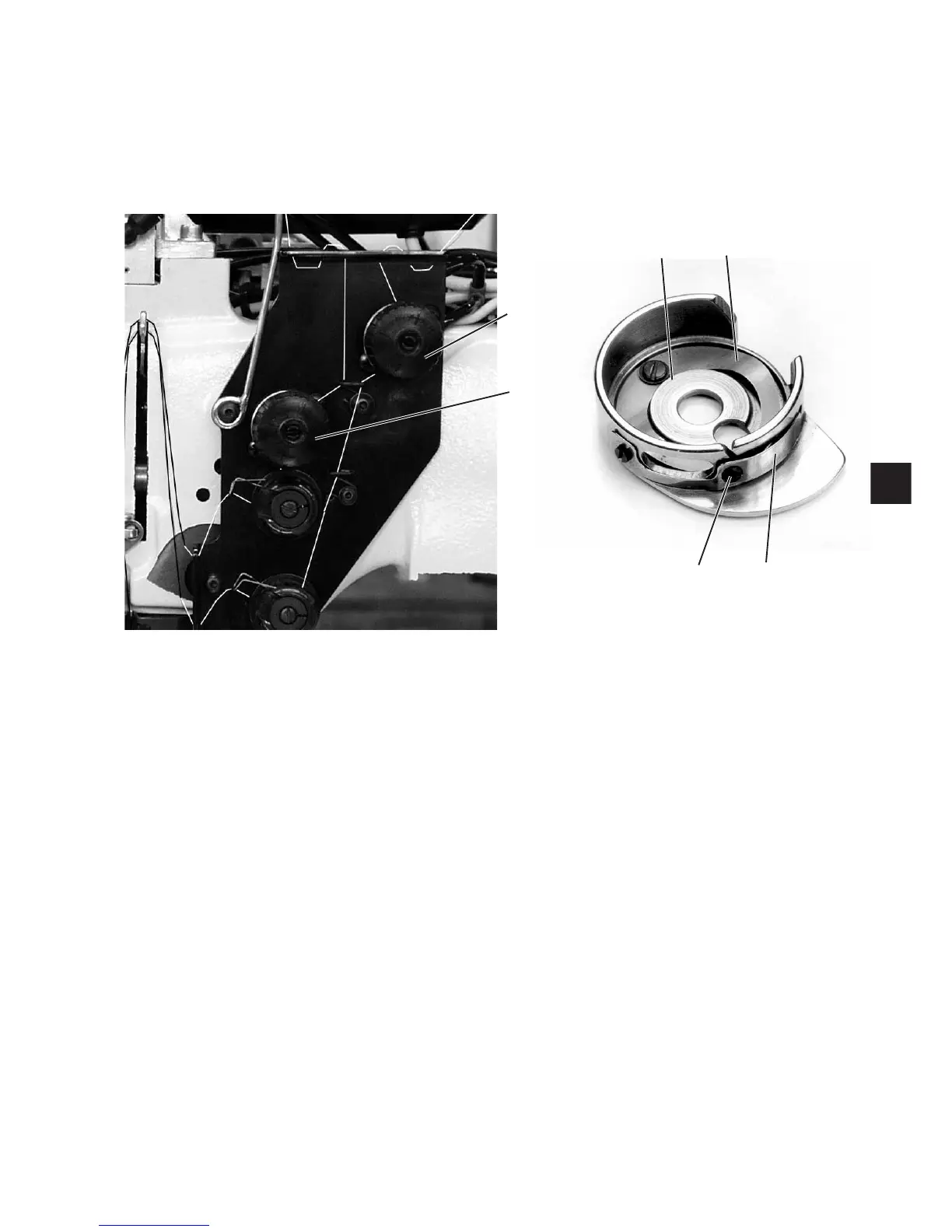

Setting the needle thread tension:

–

Adjust the needle thread tension until a uniform stitch pattern is

achieved.

–

Adjust the tension of the needle threads at knurled nut 1 (right

needle thread)

and knurled nut 2 (left needle thread).

Increase the needle thread tension: Turn to the right

Reduce the needle thread tension: Turn to the left

1

21

1

2

3

4

5

6

Loading...

Loading...