50

K800000000EJ 020650A0 170512

5.0 SENSORS

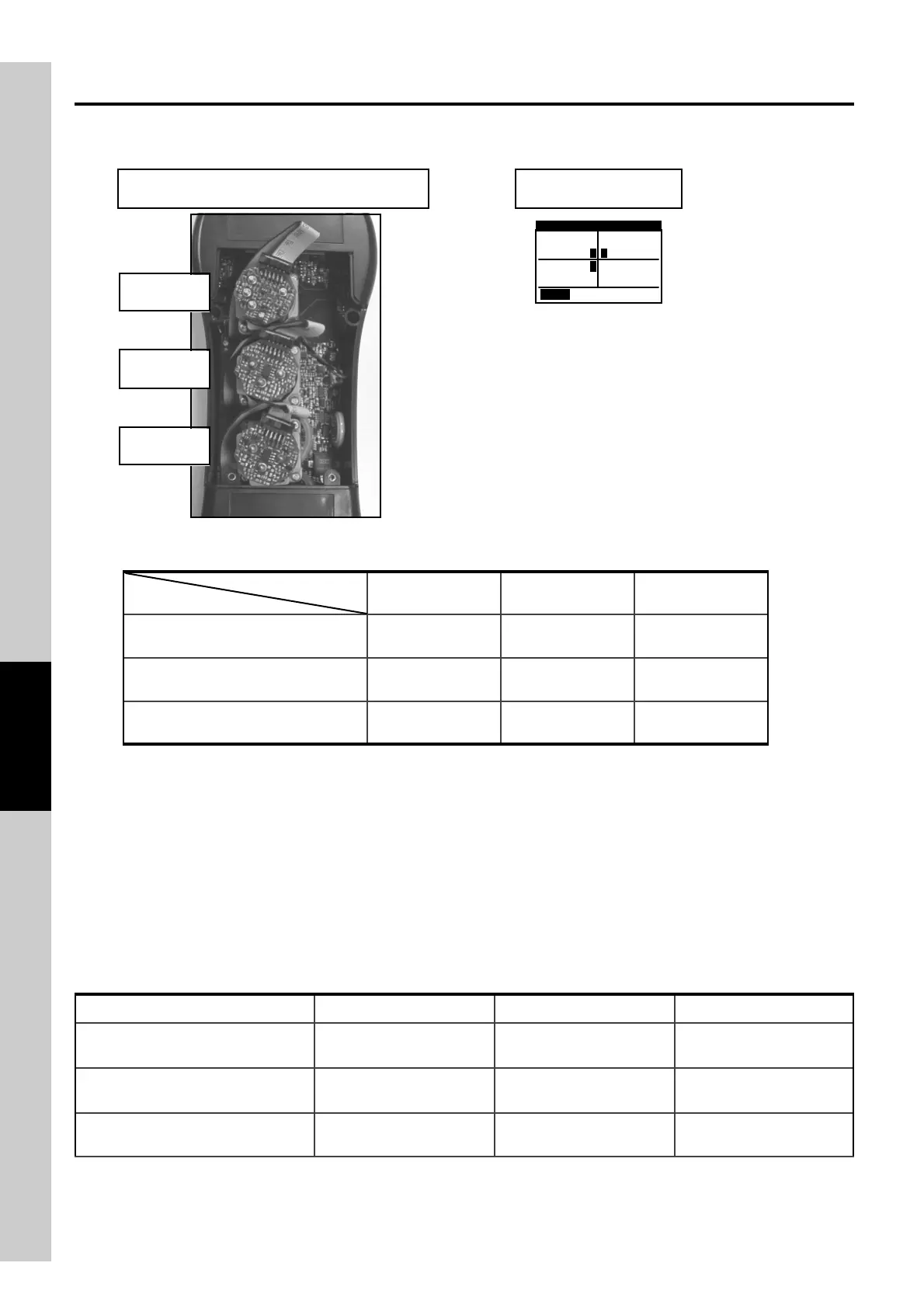

5.1 Sensors arrangement

5.2 Sensor types and relevant positioning

5.3 Gas sensor life

The gas sensors used in this instrument are electrochemical: thus, when the relative gas is detected, a chemical

reaction takes place inside them that generates an electrical current.

The electrical current acquired by the instrument is then converted into the corresponding gas concentration.

Sensor life is strongly related to the consumption of the reagents within.

Sensor characteristics diminish as the reagents are consumed and when these have been used up completely

the sensor must be replaced. The sensors must be recalibrated on a regular basis to assure measuring

accuracy: recalibration can only be performed by a qualified E Instruments Service Center. Chart 5.4 illustrates

the characteristics inherent to each sensor.

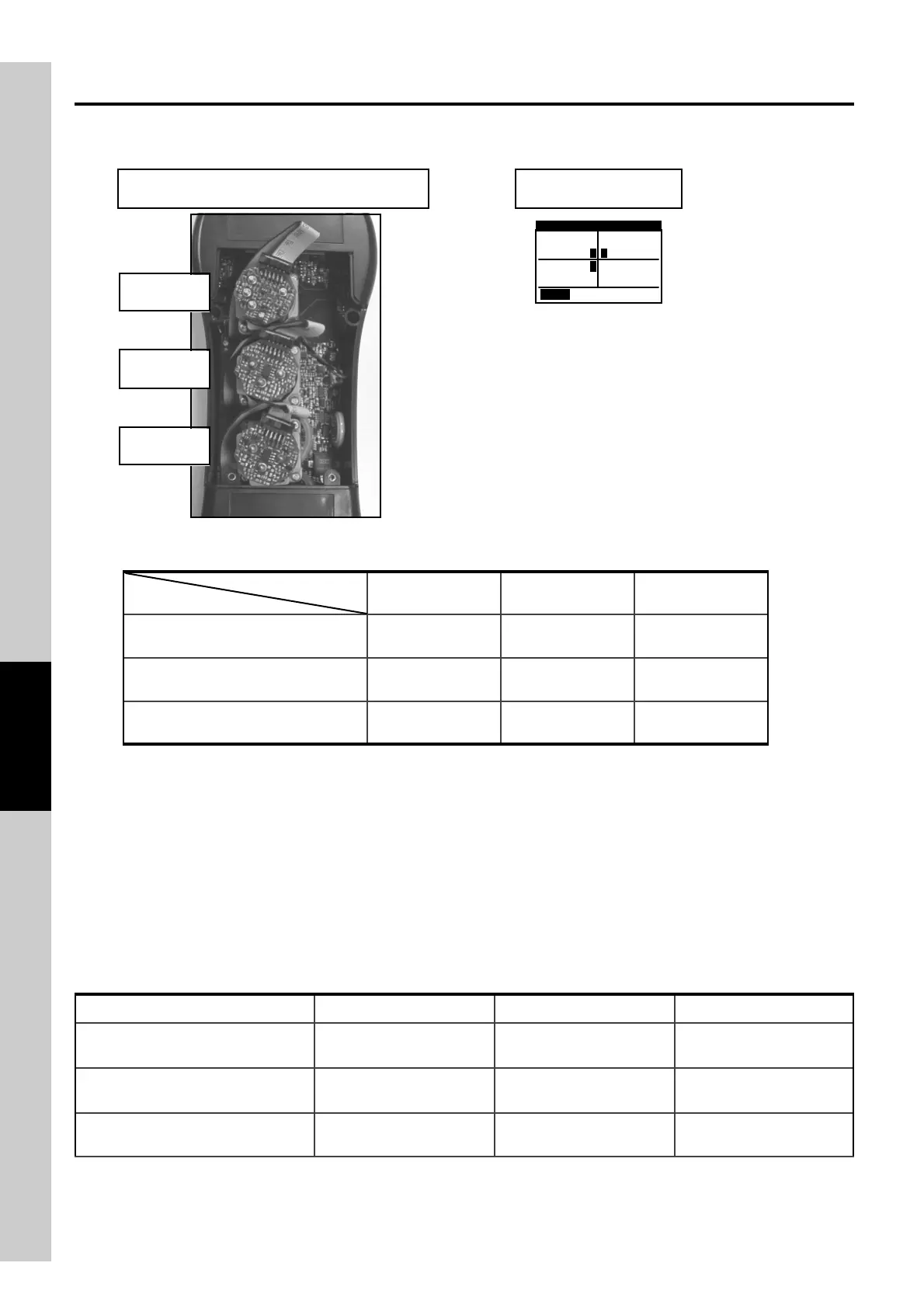

5.4 Gas sensors life table

Notes:

(1) UNI 10389-1 standard requires for the instrument calibration once per year to be performed in a laboratory

authorized to issue calibration certificates.

S1 S2 S3

FLEX-Sensor O

2

Cod. AAC SE15

FLEX-Sensor CO (Low H

2

)

Cod. AAC SE20

FLEX-Sensor NO

Cod. AAC SE10

CODE

POSITION

GRAPHICAL DISPLAY

OF ARRANGEMENT

SENSORS TYPE

QUIT

1 3

2

O

2

NO

CO

SENSORS ARRANGEMENT INSIDE

THE SENSORS COMPARTMENT

POSITION

S2

POSITION

S1

POSITION

S3

CODE MEASURED GAS AVERAGE LIFE RECALIBRATION

FLEX-Sensor O

2

Cod. AAC SE15

O

2

Oxygen

>24 months not necessary

FLEX-Sensor CO (Low H

2

)

Cod. AAC SE20

CO

Carbon Monoxi de

>36 months Yearly

(1)

FLEX-Sensor NO

Cod. AAC SE10

NO

Nitrogen Oxide

48 months Yearly

(1)

Loading...

Loading...