INTRODUCTION

1.1 What is Ceramic 3D Printing?

1.2 From 3D Design to Printed 3D Object.

Slice to GCODE

3D Design

Ceramic 3D Printing is a process whereby a real object is created from a 3D Design.

Direct Ink Writing (DIW) is one of the most common technologies used by 3D Printers

to achieve this. DIW works on an 'additive' principle by laying down material, such as

porcelain or clay, in layers to create a 3D object.

3D Design Slice to GCODE Setup Eazao 3D Printer

Printing Process

3D Printed Object

Having a 3D design is the first step to creating a 3D

Object. There are a number of free 3D Designs that

can be downloaded and printed for personal use.

Websits such as Thingiverse.com, Pinshape.com and

YouMagine.com are a good place to start, but there

are many more available!

Alternatively, you can create your own 3D Design using 3D Modelling Software.

Programs such as Sketchup or Blender allow this, however this can take some

practice before successfully modelling your 3D Design. After you've finished your 3D

Design,byou can export it as an. STL file,to be imported into a 'Slicer' program such as

Cura.

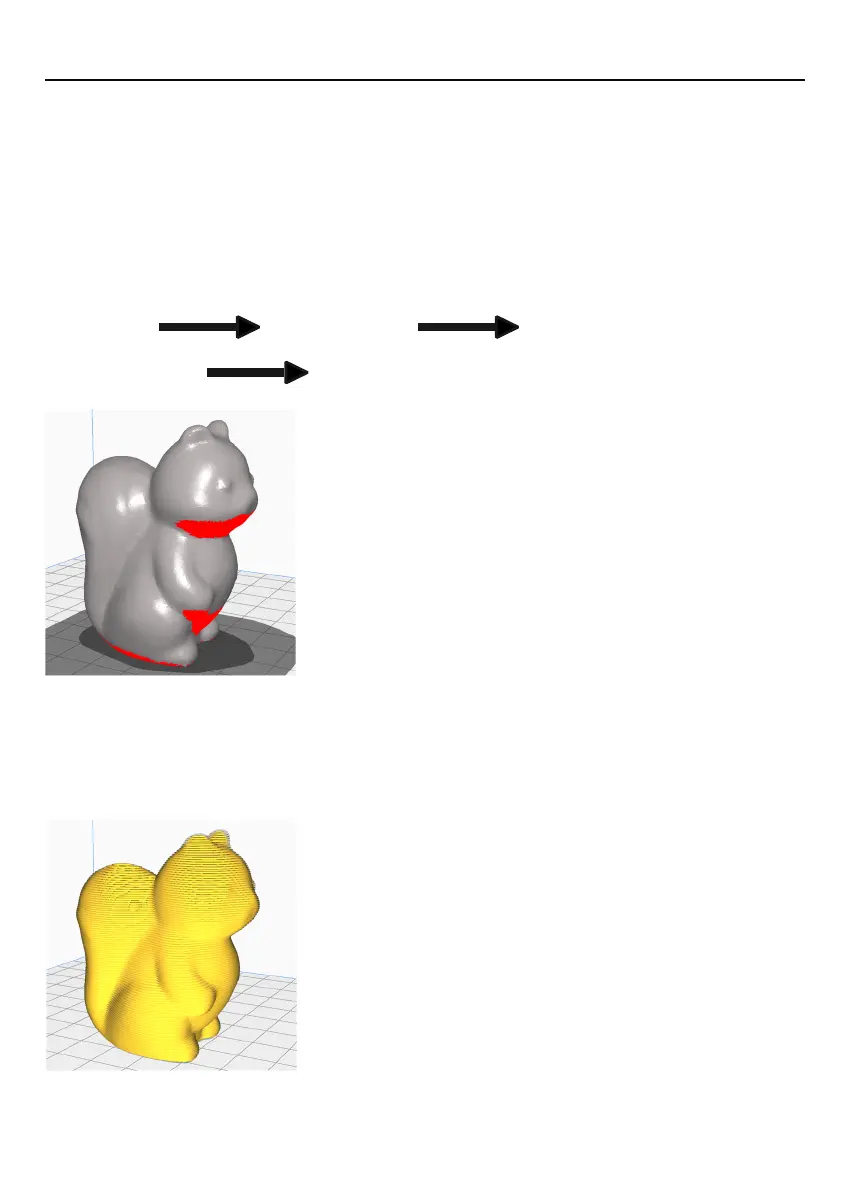

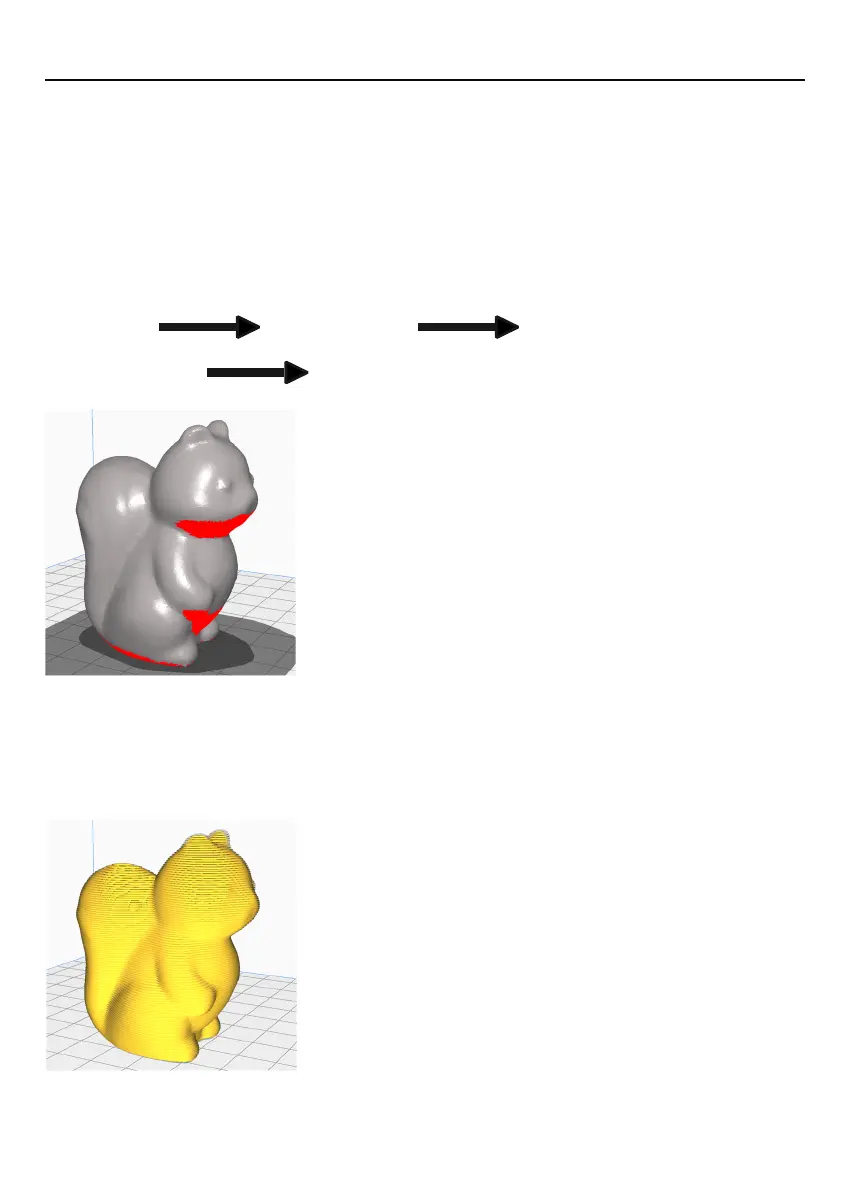

A 'Slice' converts a 3D Design (usually an .STL or .AMF

format)into individual layers. It then generates the

machine code (such as GCODE) that the 3D Printer

will use for printing.

We recommend the program Cura as it uses a simple interface and includes a large

amount of support material.

1

Loading...

Loading...