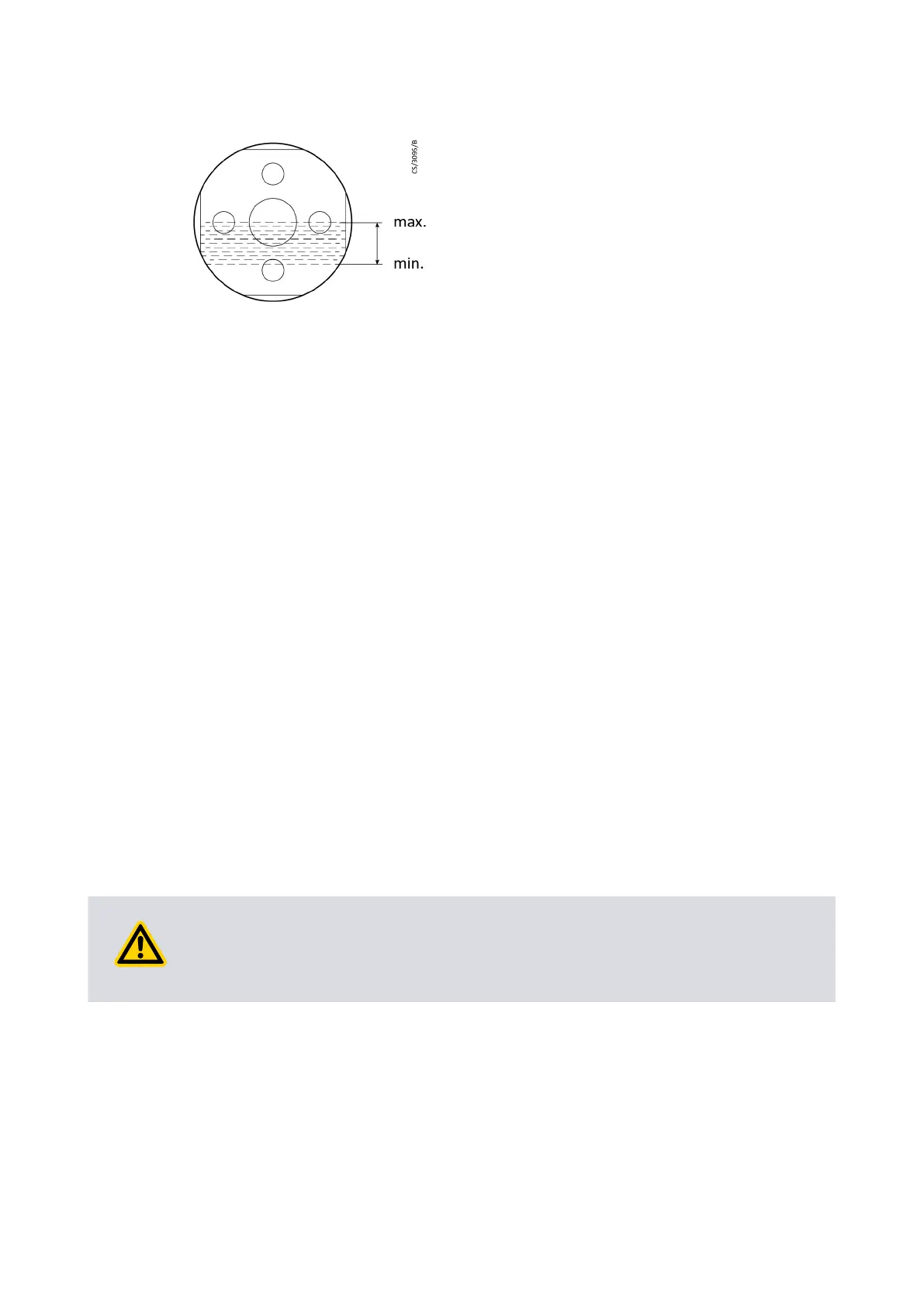

Figure 5 Oil level at pump standsll

7.1 Placement

Place the pump system on a at and level surface.

The pump is designed for operaon in building. We recommend leaving the crane eyes

screwed in.

Remove the covers and blank anges on the pump just before ng the pump so that the

assembly work can be performed under the cleanest condions.

Check whether there is any desiccant present in the intake area and remove it.

The pumps are supplied lled with synthec oil. Nothing will have to be relled. Check the

oil levels through both oil level glasses.

If one of the oil levels is found to be incorrect, contact Edwards.

Fit suitable bolts through the xing holes in the mounng feet, to secure the pump in

posion.

7.2 Normal operaon

The EDS pumps are suitable for a wide range of industrial and chemical applicaons.

Edwards has a dedicated team of applicaons engineers who can help you determine the

best EDS system for your applicaon.

If you use the system on an applicaon for which it is not suitable, you may invalidate your

warranes. If in doubt, contact Edwards.

7.2.1 Abnormal operaon

WARNING: UNPREDICTABLE FAILURES

Use of equipment in abnormal operaons can lead to failures that result in injury or

death. Misuse of the pump as described below is strictly prohibited.

▪

Use of the EDS as a posive displacement compressor

▪

Operaon outside the limits of operaon further dened in this manual

▪

Operaon outside the limits of the ATEX marking

▪

Reverse rotaon of the EDS

▪

Pumping gases and vapours for which the materials (see Technical data

(on page 17)

) of

the pump are not suitable

▪

Pumping of substances and mixtures (gases, liquids and solids) where the explosion

hazard results exclusively from the presence of explosive substances

▪

Pumping gases that tend to self-decompose, or that are chemically unstable

Page 24

A41802880_C - Installaon

Loading...

Loading...