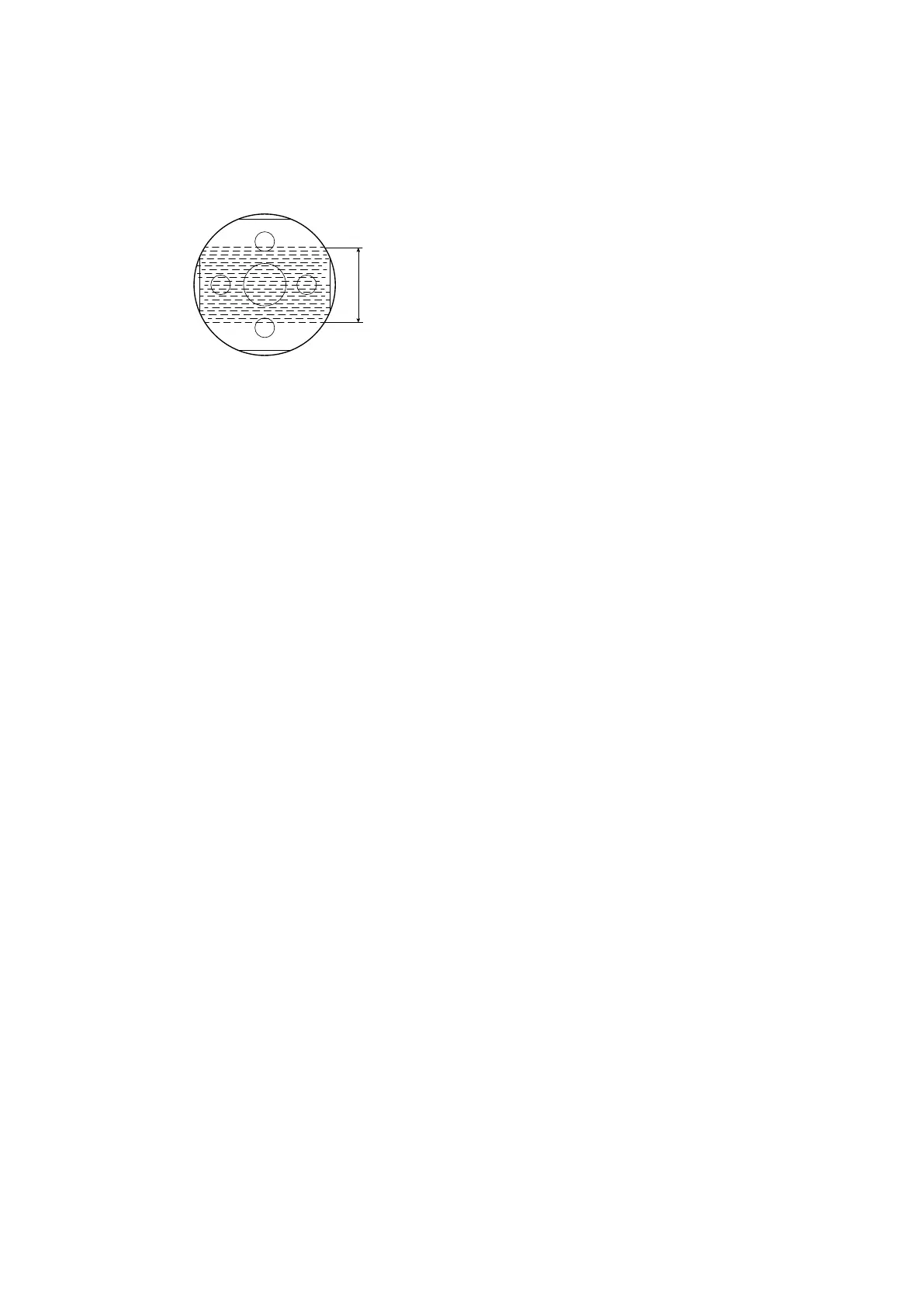

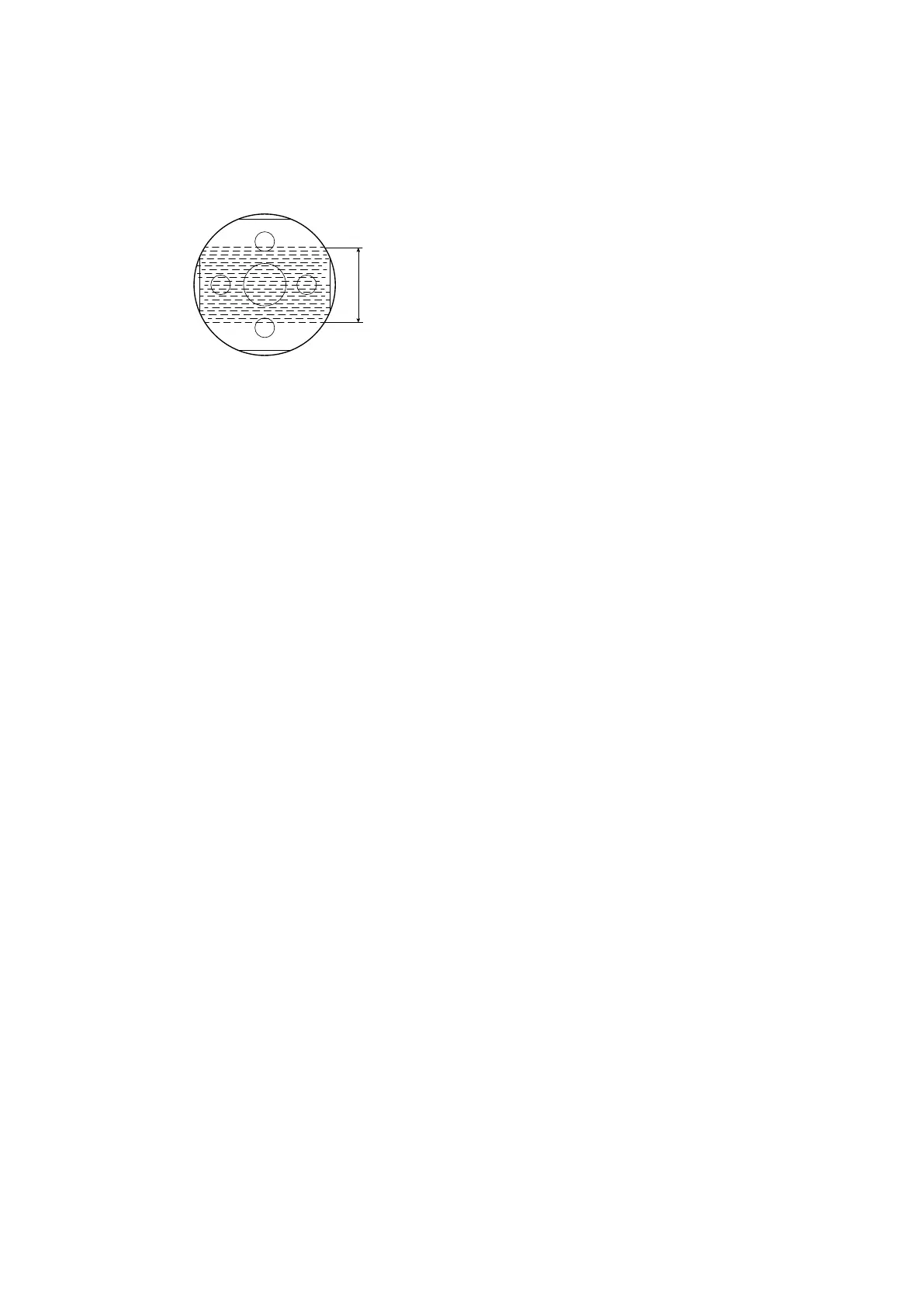

Cooling-water should be visible in the cooling-water level sight glass above the gearbox. If no

water or Drystar mixture is visible, the system will require addional coolant. Fill up the

system with adequate coolant, so that the sight glass is completely lled up.

Figure 19 Cooling water level

9.5 Inspect pipelines and connectors

Inspect all of the cooling system and purge gas pipelines and connecons. Check that they

are not corroded or damaged. Replace any of the pipelines and connecons that are

corroded or damaged. Check that all connecons are secure. Tighten any loose connecons.

Inspect all of the electrical cables. Check that they are not damaged and have not

overheated. Replace any cables that are damaged or have overheated. Check that all of the

electrical connecons are secure. Tighten any loose connecons.

Inspect all of the process inlet and exhaust pipelines and connecons. Check that they are

not corroded or damaged. Replace any of the pipelines and connecons that are corroded or

damaged. Check that all connecons are secure. Tighten any loose connecons.

Page 41

A41802880_C - Maintenance

Loading...

Loading...