4. Preload check

WARNING:

Allow the pump r

otor to stop before you remove the pump from your vacuum system

for maintenance procedures.

NOTICE:

If the pump has suer

ed any damage (i.e. the rotor does not spin freely or quietly), it

is recommended that the service is not carried out. Contact local service centre for

advice.

Ensure all tools are clean and free of dirt and grease to avoid contaminaon of the

rotor.

Aer the bearing change the bearing preload must be checked. To become familiar with

how to check bearing preload, we recommend you perform a check at rst.

Preload is the process where a permanent thrust load is applied to the mechanical

bearing. Thrust is applied by the misalignment between the inner stac and the outer

rotang passive magnec bearing located at the inlet of the pump.

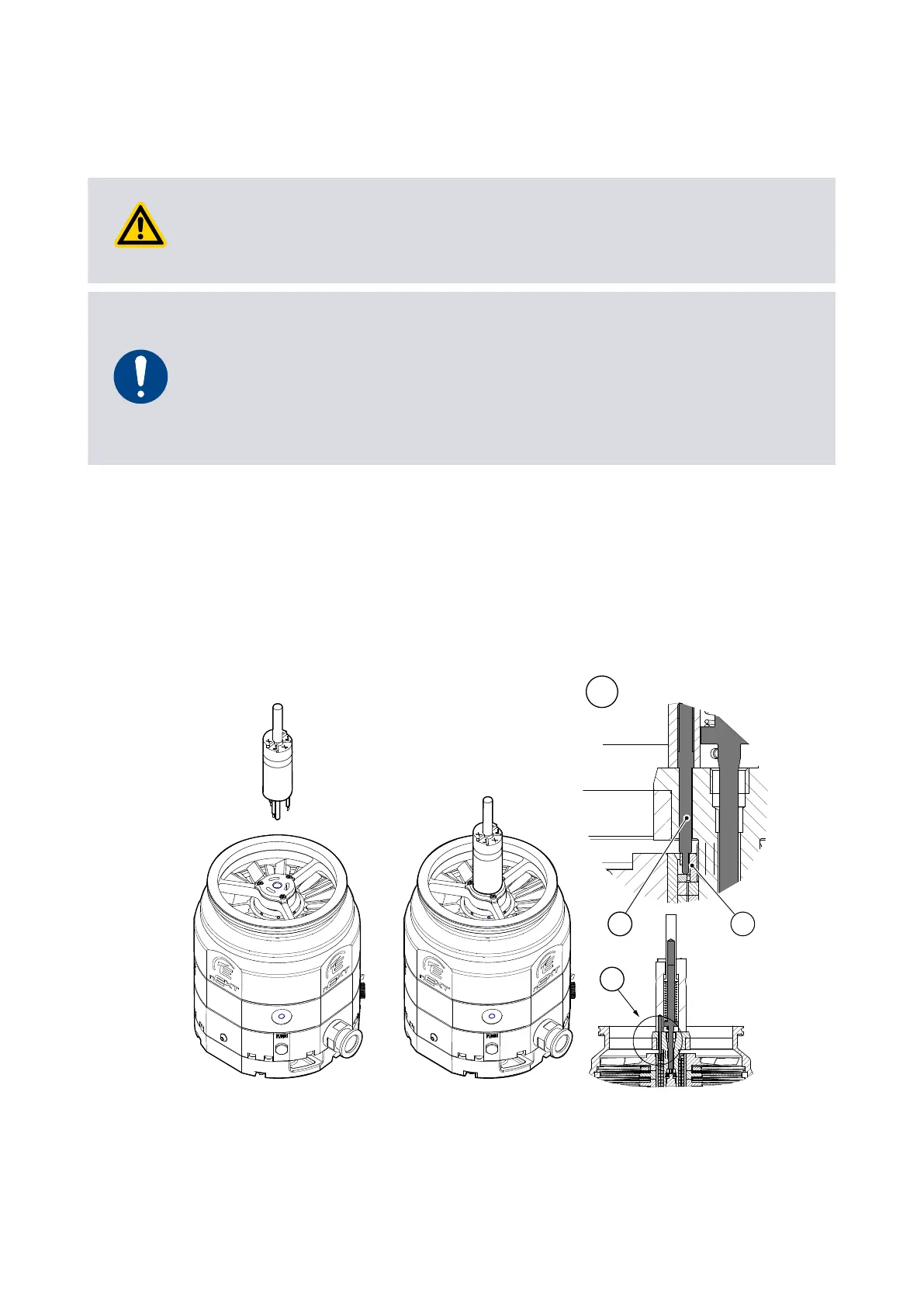

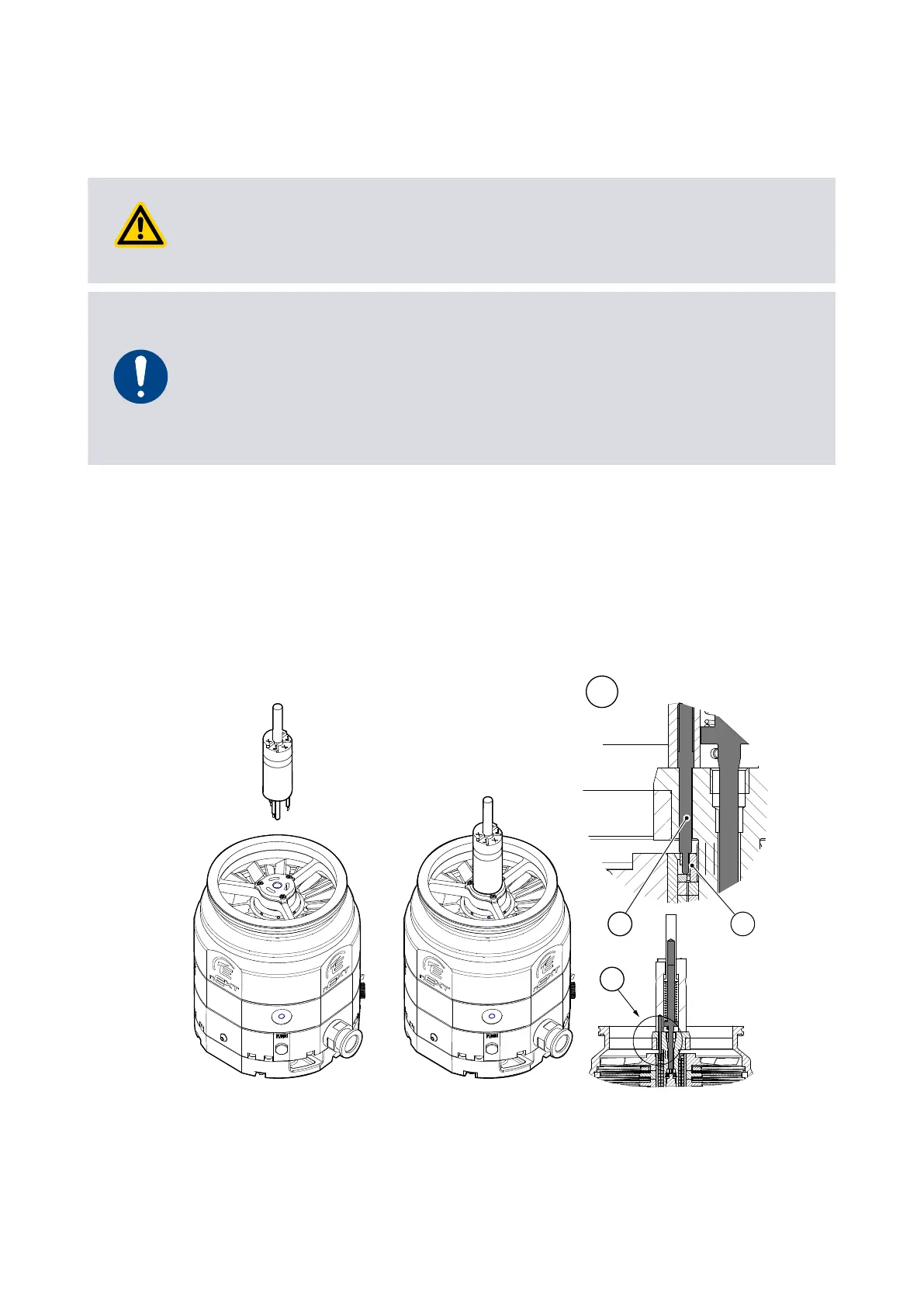

Place the pump in the vercal posion.

Figure 3 Check the bearing preload

1. Adjuster leg 2. Bearing adjuster nut1. Adjuster leg 2. Bearing adjuster nut

Place the preload tool onto the inlet of the turbomolecular pump. The force probe must

be loca

ted in the centre of the pump inlet with the adjuster legs engaged on the

06/2021 - ©Edwards Limited

Page 10300872820_002_C2

B8J203880_C

300872820_002_C2 - Preload check

Loading...

Loading...