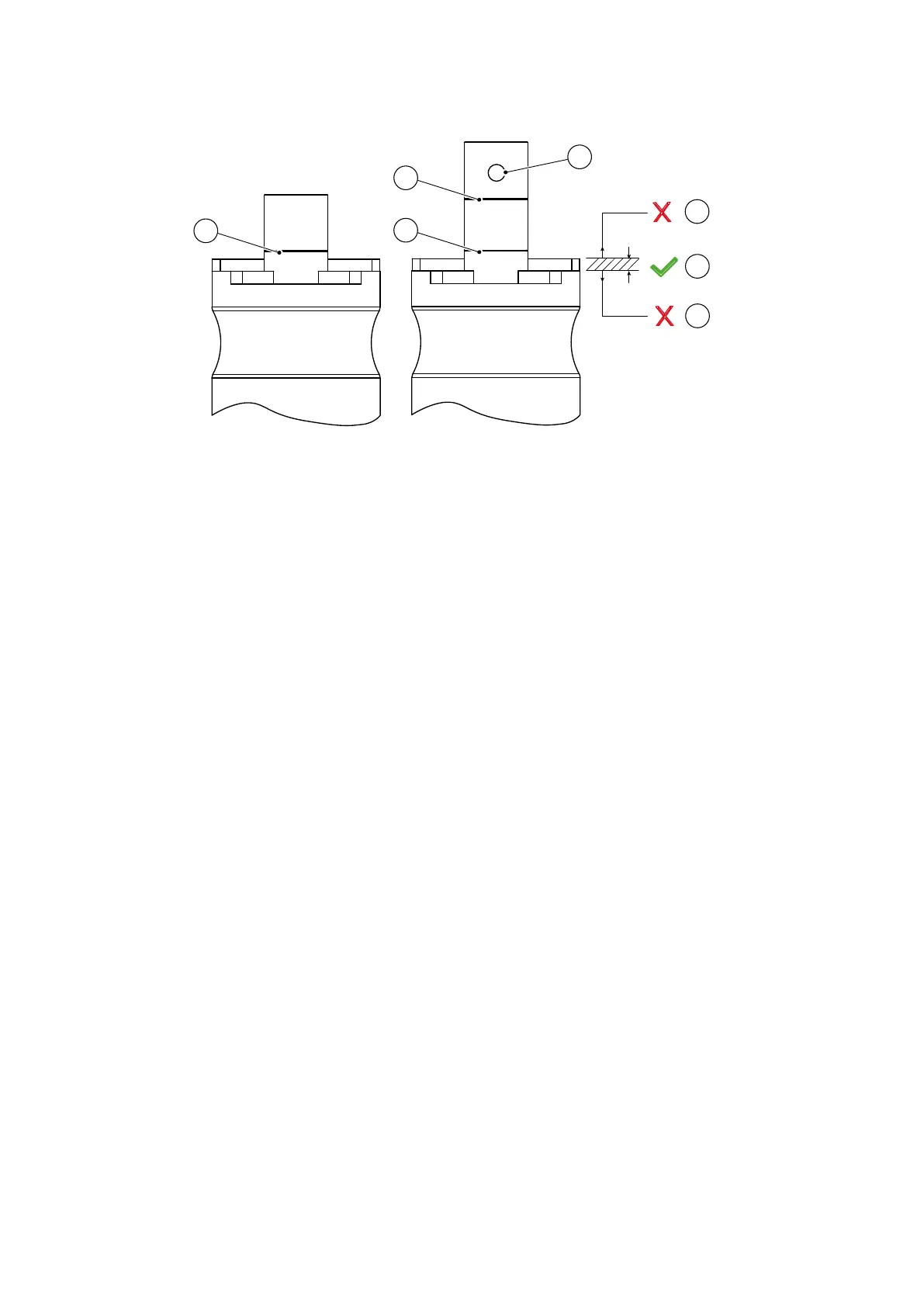

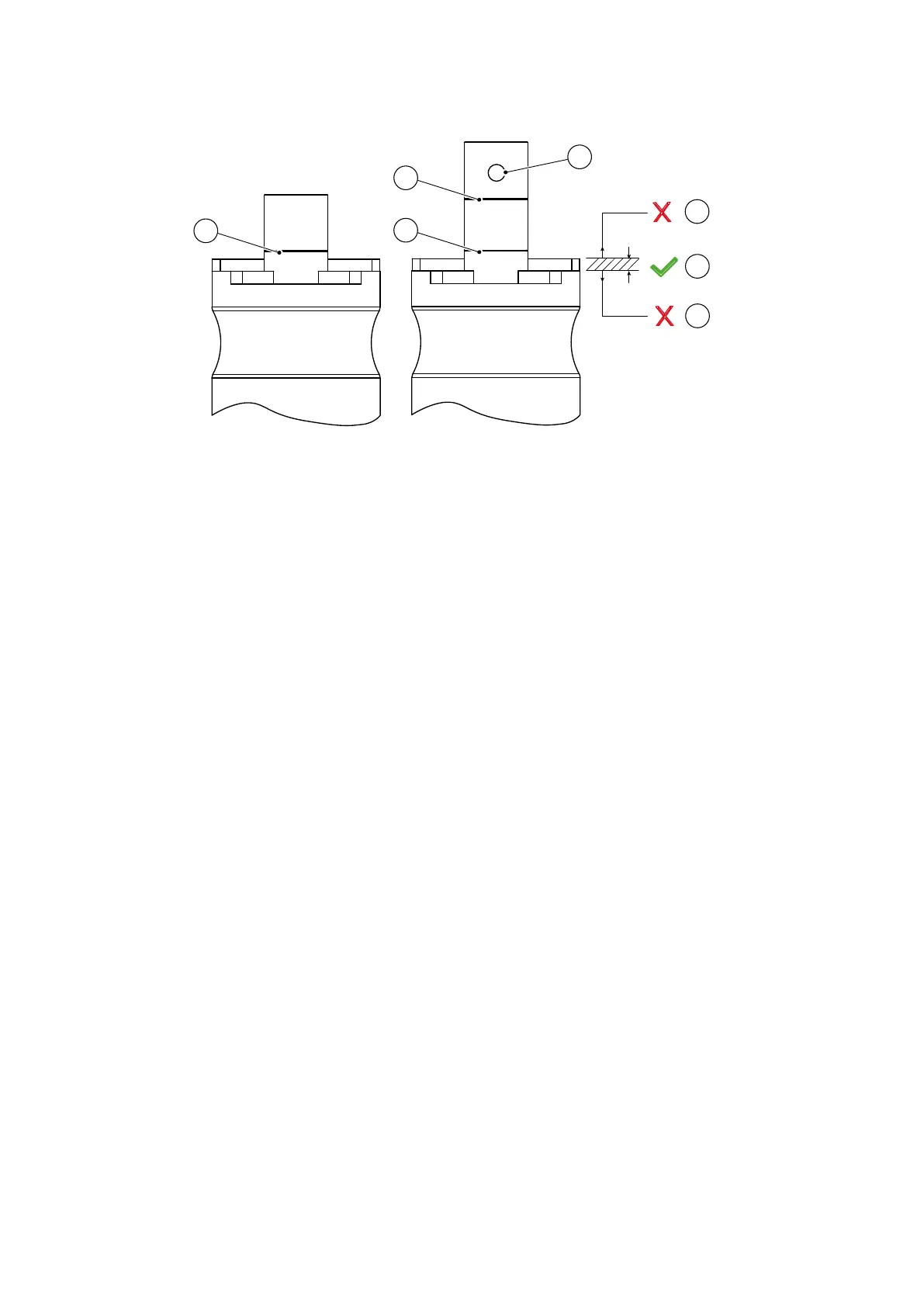

Figure 25 Preload tool (pass/fail indicaon)

5

nEXT 730D, 930D nEXT 1230H

1

2

1

BC-0056-A

4

3

6

1. Fail

2. Pass

3. Pass/ Fail test indicator (only one marker for all pump models)

4. Pass/ Fail test indicator (upper marker for pump models with part nos without

"INV")

5. Pass/ Fail test indicator (lower marker for pump models with part nos with "INV")

6. Hole for banana plug

6.2 Clearance check

Be

fore installaon check the pump clearance.

Use the end of a pen or a similar tool to carefully rotate the rotor. While the rotor is

turning listen out for any clashing between the rotang and stac parts. Ensure the rotor

turns freely. If the rotor does not turn freely, contact your supplier.

6.3 Bearing monitoring and condioning system

To ensure maximum reliability and bearing life nEXT pumps have an integrated system to

manage the bearing condion. The status is indicated by a blue LED on the pump.

The pumps have an integrated baery-backed real me clock that is constantly

monitoring pump storage me.

The TMP motor controller when powered uses its processor and when unpowered the

real me baery backed clock to monitor the TMP inacvity me. Inacvity me refers

to both when the TMP is unpowered and when the TMP is powered but at rest. When

inacvity me exceeds:

▪ the pr

e-dened period of 12 mon

ths, a bearing condioning is required and

"Bearing Run in Mode" (BRIM) will commence at the next pump start.

▪ the pre-dened period of 3 years, a bearing replacement is required. The customer

will be alerted by the major service due indicator on the STATUS LED (yellow) and

on the Bearing LED (blue). Once the bearing is replaced and the major service

reset, a bearing condioning will be required and will commence at the next pump

start.

06/2021 - ©Edwards Limited

Page 26300872820_002_C2

B8J203880_C

300872820_002_C2 - Assembly

Loading...

Loading...