STP-301/451 Series Instruction Manual

13-8

注意

!

CAUTION

!

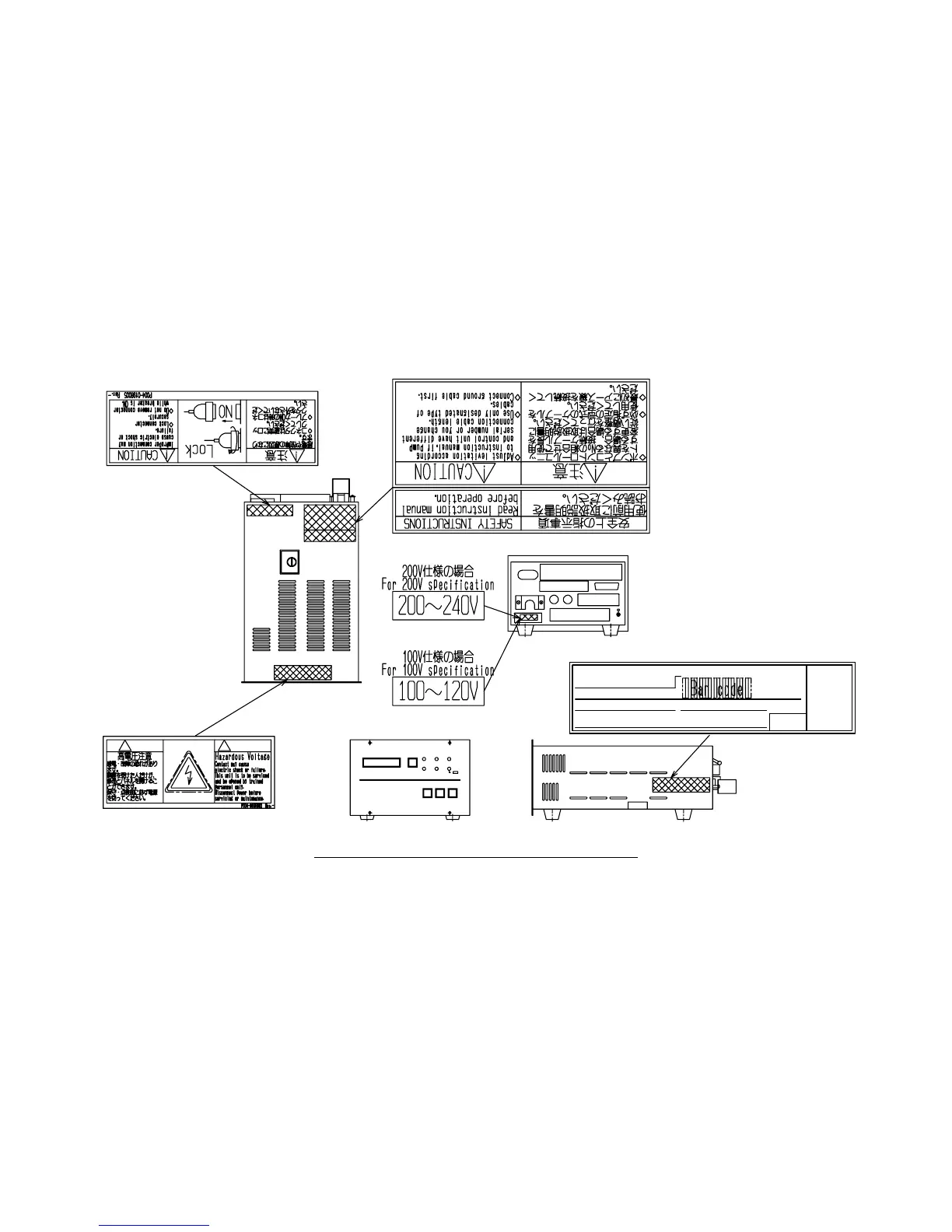

Turbomorecular pump Control Unit

SERIAL No.:

MODEL: SCU-

MANUFACTURING DATE:

WEIGHT: kg

MANUFACTURED BY: Edwards Japan Limited.

1078-1, Yoshihashi, Yachiyo-shi, Chiba, Japan

CE

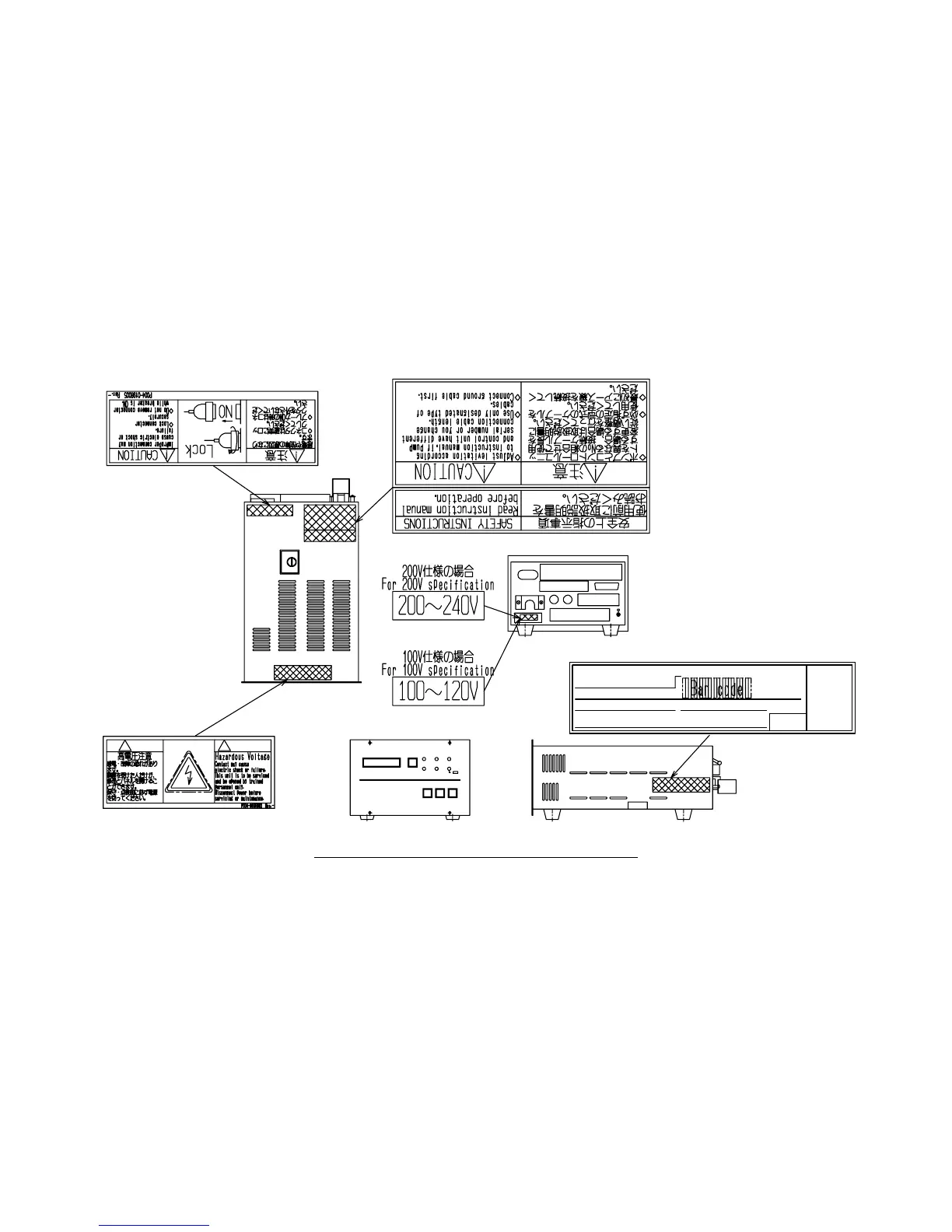

Figure 13.5 Label Affixing Positions for the STP Control Unit

Loading...

Loading...