11

3.5 Checking and adjusting the angle of the tool holder

When creating scratches using the optional cross cut tools (see “Spare parts

and accessories” on page 22), it is essential that the angle of the tool is adjusted

until the cutting edge of the tool is parallel to the surface of the specimen.

3.5.1 Checking the angle of the tool holder

To check that the angle of the tool is correct:

1. Fit the cross cut tool.

2. Set the pressure to 1 bar.

3. Perform a scratch test.

4. Inspect the specimen:

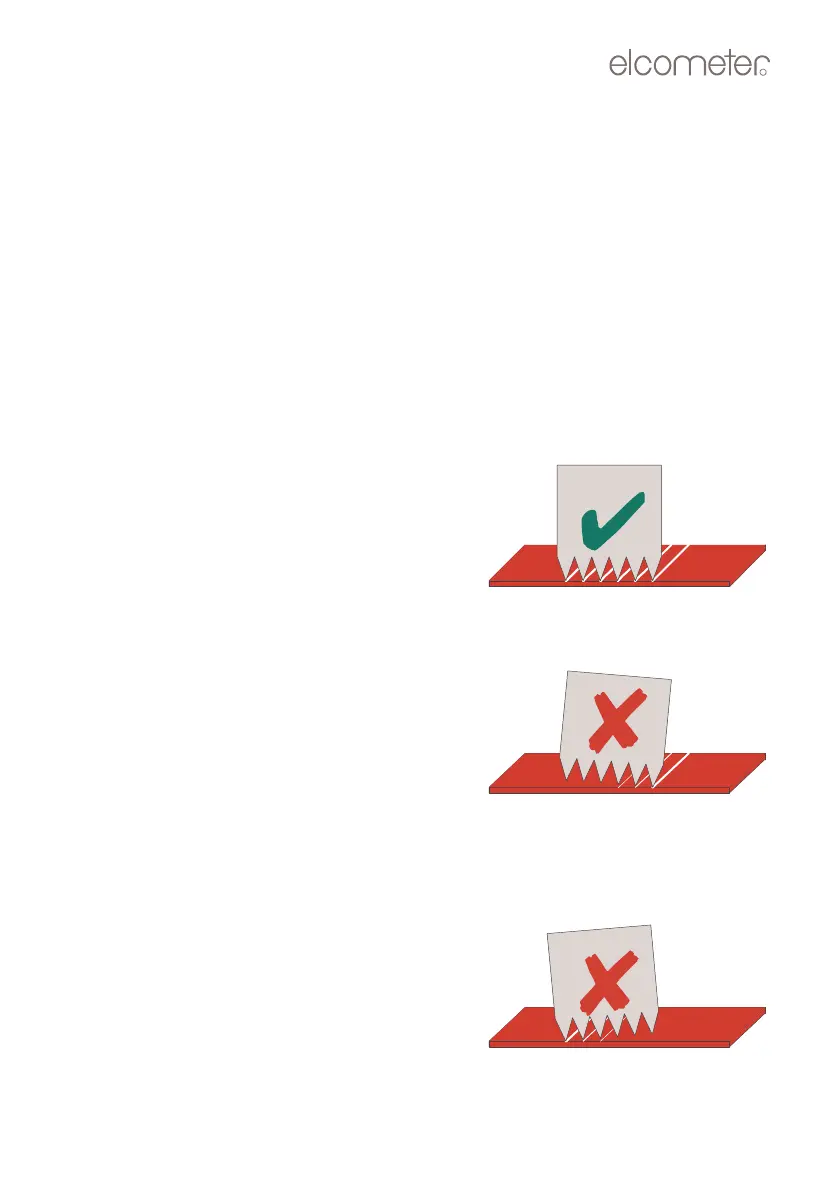

Depth of scratches is even front to back

The tool is correctly adjusted; all teeth of

the cross cut tool are in contact with the

surface of the specimen and the depth of

cut is equal.

No adjustment is required.

Scratches at back, no scratches at front

The cross cut tool is inclined; scratches at

the back of the specimen are deeper than

those at the front.

Adjustment is required; see “Adjusting the

angle of the tool holder” on page 12 and

rotate the micrometers towards zero

(direction A).

Scratches at front, no scratches at back

The cross cut tool is inclined; scratches at

the front of the specimen are deeper than

those at the back.

Adjustment is required; see “Adjusting the

angle of the tool holder” on page 12 and

rotate the micrometers away from zero

(direction B).

Op_1535_01 A5.fm Page 11 Wednesday, August 8, 2007 3:59 PM

Loading...

Loading...