EMC INDUSTRIAL GROUP LTD Setup

MW61A_IM_ALL_SV6.09d_en 14/47

Setting the COM1 Modbus Address

Before a multidrop system will operate, the addresses in each of the ModWeigh units will need to be set

differently. This can be done by wiring a link or resistor to the ADS terminal where available. See the

table on the connection diagram. Alternatively the address setting can be changed in each unit using a

display connected to its COM1.

The following procedure is used to set a units address.

1. Press the Q key to access the setup menu.

2. Key in the quick key code 2512 to select the ‘COM1&2 modbus address’ step.

3. Press the EDIT key. (If editing is locked, key in the password 111 and press ENTER).

4. Enter the desired address (1, 2 or 3 etc.) and press ENTER.

5. Press and hold the BACK key to return to normal operation.

6. Repeat for each of the units which are to be used on the bus.

When the multidrop system is then connected and powered, the display should be able to see each of

the ModWeigh systems. This is done by pressing the SELECT key on the display.

SETTING UP

Setup

ModWeigh instruments must be calibrated for each specific application. The parameters stored are col-

lectively known as the Setup.

Description

Press the Q key to access the setup menu.

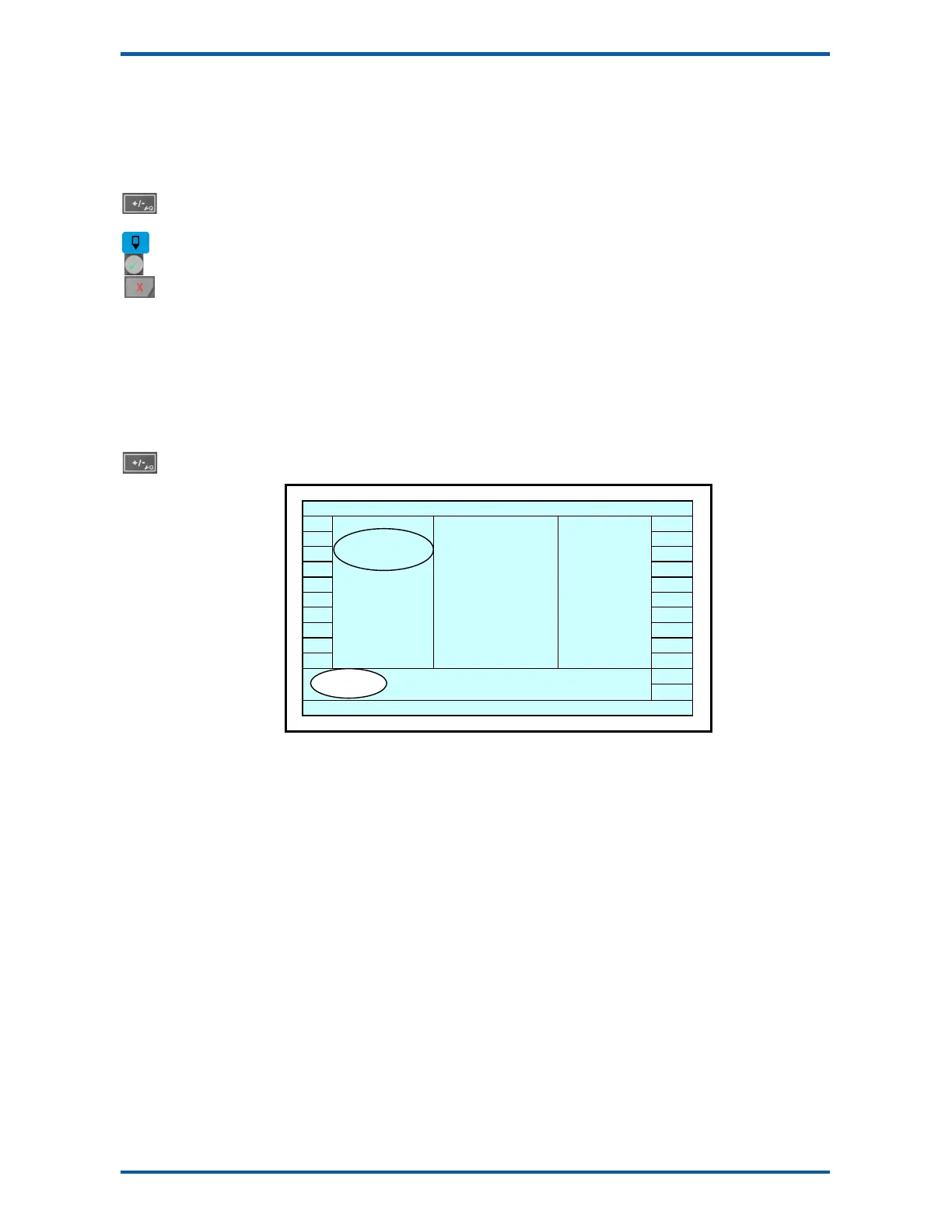

The setup is divided into sections as shown in the following diagram.

SETUP

Basic Settings

AI1 AO1

AI2 AO2

IN1 OUT1

IN2 OUT2

IN3 OUT3

IN4 OUT4

IN5 OUT5

IN6 OUT6

IN7 OUT7

IN8

Inputs

Internal Signals

Outputs

OUT8

COM1

Communications & Display

COM2

Information, Resets & Final Calibration

Setup Diagram

The Setup contains

Settings

and

Macros

which are described next.

Settings

Most of the setup for a system involves setting calibration constants which for example calibrate the

loadcell input, the 4-20mA outputs and the operation of relays etc. These settings are simple numeric

values.

Macros

Macros are used to store short programs which are used to construct text strings to output to the

printer, perform arithmetic calculations and other special control functions. Macros are a collection of

program segments which can call one another as subroutines. They have structured if/then/else state-

ments and program looping constructs.

A macro is a sequence of numbers (bytes with values of 0 to 255).

Menus

All the setup parameters are contained within a menu structure which follows the setup sections.

Basic Settings

Inputs

Internal Signals

Outputs

Communications & Display

Information, Resets & Final Calibration

Factory Settings

Loadcell

Calibration

Loading...

Loading...