Safety

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running the

Motor

Optimization

SMARTCARD

Operation

Onboard

PLC

Advanced

Parameters

Technical

Data

Diagnostics

UL

Information

Quantum MP User Guide 143

Issue: A4 www.emersonct.com

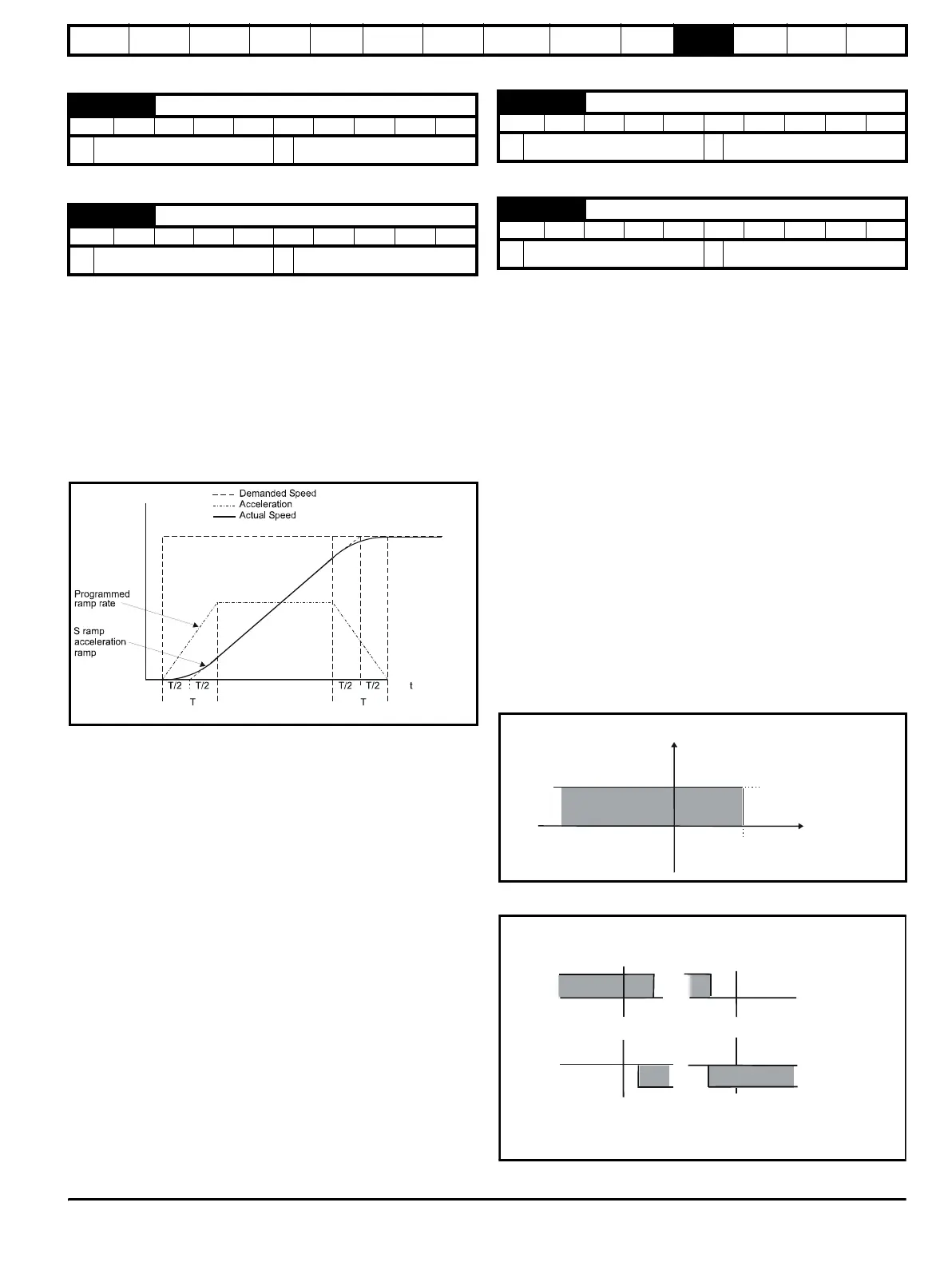

11.23.2 S ramps

Setting this parameter enables the S ramp function.

This parameter defines the maximum rate of change of acceleration/

deceleration. If the S ramp is disabled (Pr 2.06 = 0) a linear ramp is used

and the time in seconds taken for the ramp output to change by speed (

w*) is given by:

Speed

T

Ramp =

w* x A / See Pr 2.39

Where A is the selected ramp rate in s / See Pr 2.39

If the S ramp is enabled (Pr 2.06 = 1) then the ramp time is extended as

shown in the diagram below.

The time taken in seconds for the ramp output to change by speed (w*)

is given below. Two cases are given because the total ramp time must

be calculated with a different equation depending on whether the

acceleration is able to reach the selected ramp rate (A1) or not. If the

required change is small the selected ramp rate is not reached and the

ramp does not include the central linear ramp region. If the required

change is larger the ramp does include the central linear region as

shown in the diagram above.

Speed

*

linear

= 1000 x J / A1

2

where:

A = selected ramp rate

J = Pr 2.07

If the required change is less than *

linear

then T

Ramp1

should be used,

but if the speed change is greater or equal to s*

linear

T

Ramp2

should be

used.

T

Ramp1

= 2 (* x Pr 2.07 / 1000)

T

Ramp2

= (* x A / 1000) + (Pr 2.07 / A)

The default values for the ramp rate and S ramp acceleration limit have

been chosen such that for the default maximum speed, the curved parts

of the S ramp are 25% of the original ramp if S ramp is enabled.

Therefore the ramp time is increased by a factor of 1.5.

11.23.3 Torque modes

The value of this parameter refers to switches TM0 to TM3 on Menu 4

diagram.

When this parameter is set to 1, 2 or 3 the ramps are not active while

the drive is in the run state. When the drive is taken out of the run state,

but not disabled, the appropriate stopping mode is used. It is

recommended that coast stopping or stopping without ramps are used.

However, if ramp stop mode is used the ramp output is pre-loaded with

the actual speed at the changeover point to avoid unwanted jumps in the

speed reference.

0: Speed control mode

The torque demand is equal to the speed loop output.

1: Torque control

The torque demand is given by the sum of the torque reference and

the torque offset, if enabled. The speed is not limited in any way,

however, the drive will trip at the overspeed threshold if runaway

occurs.

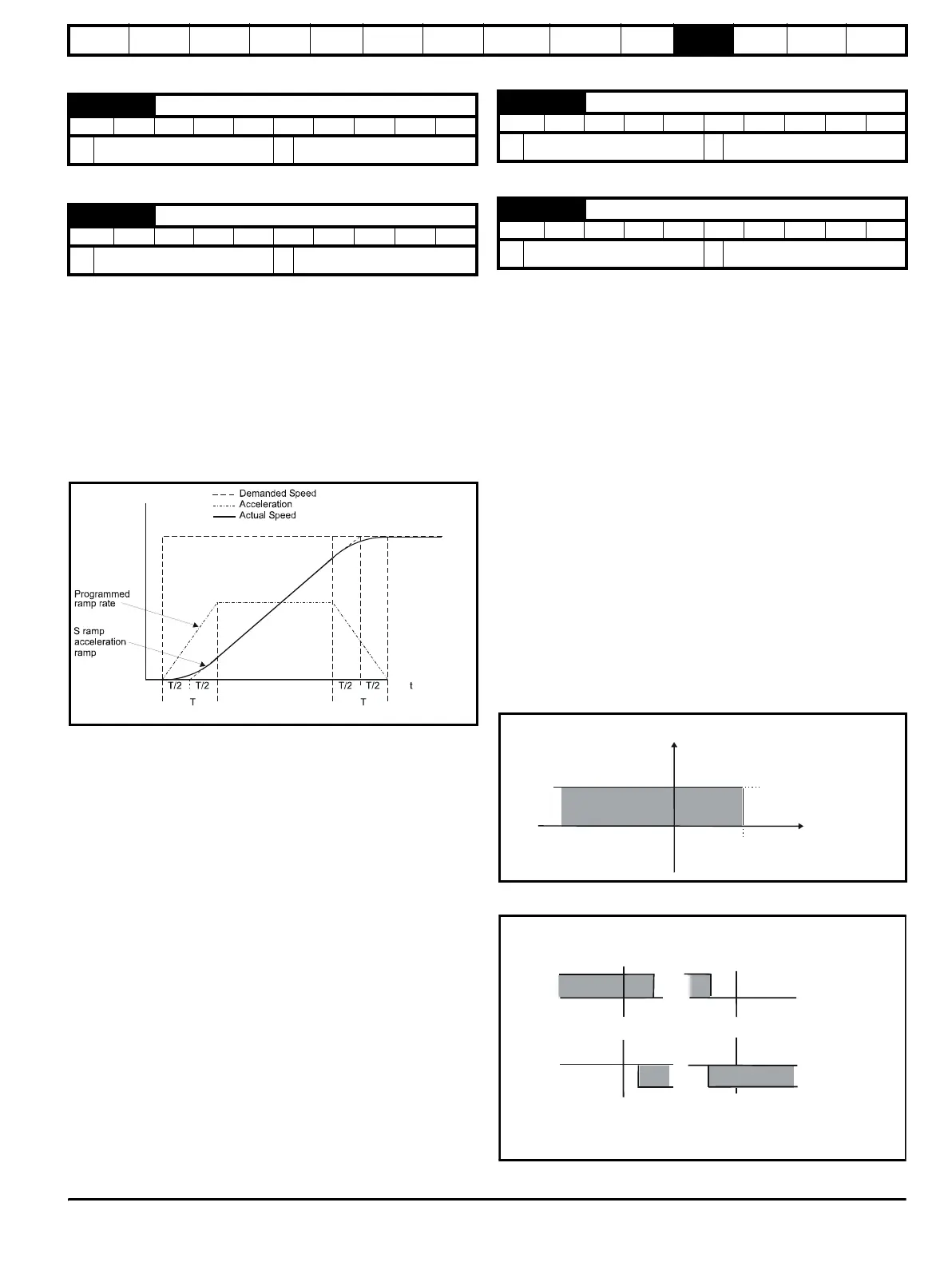

2: Torque control with speed override

The output of the speed loop defines the torque demand, but is

limited between 0 and the resultant torque reference (Pr 4.08 +

Pr

4.09 (if enabled)). The effect is to produce an operating area as

shown below if the final speed demand and the resultant torque

reference are both positive. The speed controller will try and

accelerate the machine to the final speed demand level with a

torque demand defined by the resultant torque reference. However,

the speed cannot exceed the reference because the required torque

would be negative, and so it would be clamped to zero.

Depending on the sign of the final speed demand and the resultant

torque the four areas of operation shown below are possible.

This mode of operation can be used where torque control is required, but

2.06 S ramp enable

RW Bit US

OFF (0) or On (1)

EUR: OFF (0), USA: On (1)

2.07 S ramp acceleration limit

RW Bit US

0.000 to 100.000 s

2

/1,000rpm

3.600

4.08 Torque reference

RW Bi US

±USER_CURRENT_MAX %

0.00

4.11 Torque mode selector

RW Uni US

0 to 4

0

4.08

Pr (if enabled)

4.09

Pr

3.01

Speed

Current

+ final speed demand

+ resultant torque

- final speed demand

+ resultant torque

+ final speed demand

-resultant torque

- final speed demand

- resultant torque

Loading...

Loading...