Safety

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running the

Motor

Optimization

SMARTCARD

Operation

Onboard

PLC

Advanced

Parameters

Technical

Data

Diagnostics

UL

Information

70 Quantum MP User Guide

www.emersonct.com Issue: A4

SP03 (Pr 0.63, 3.12) operates in the feed-forward path of the speed-

control loop in the drive. See Figure 11-3 on page 104 for a schematic of

the speed controller. For information on setting up the speed controller

gains, refer to Chapter 8 Optimization on page 78.

6.1.6 Serial interface

* only applicable to Modbus RTU mode

This parameter can be changed via the drive keypad, via a Solutions

Module or via the comms interface itself. If it is changed via the comms

interface, the response to the command uses the original baud rate. The

master should wait at least 20 ms before send a new message using the

new baud rate.

Used to define the unique address for the drive for the serial interface.

The drive is always a slave.

Modbus RTU

When the Modbus RTU protocol is used addresses between 0 and 247

are permitted. Address 0 is used to globally address all slaves, and so

this address should not be set in this parameter

ANSI

When the ANSI protocol is used the first digit is the group and the

second digit is the address within a group. The maximum permitted

group number is 9 and the maximum permitted address within a group is

9. Therefore, Si02 (Pr 0.67, 11.23) is limited to 99 in this mode. The

value 00 is used to globally address all slaves on the system, and x0 is

used to address all slaves of group x, therefore these addresses should

not be set in this parameter.

6.1.7 Speed feedback

0, drv: Drive encoder

The position feedback from the encoder connected to the drive itself

is used to derive the speed feedback for the speed controller and to

calculate the motor rotor flux position.

1, Slot1: Solutions Module in slot 1

The position feedback from the Solutions Module in Solutions

Module slot 1 is used to derive the speed feedback for the speed

controller and to calculate the motor rotor flux position. If a position

feedback category Solutions Module is not installed in slot 1 the

drive produces an EnC9 trip.

2, Slot2: Solutions Module in slot 2

3, Slot3: Solutions Module in slot 3

4, tACH: Tachometer

5, ESt.SPEED: Estimated speed

Defines the rating of the tachometer installed to the motor. This

parameter should be set slightly above or below the nominal value if the

user wishes to trim out the tolerance build ups in the feedback

electronics.

The input electronics for the tachometer input can be configured in 3

ways.

Provided the tachometer voltage rating parameter for the tachometer is

correct this parameter shows the tachometer speed in rpm.

When Ab, Fd, Fr are used the equivalent number of encoder lines per

revolution must be set-up correctly in Fb05 (Pr 0.75, 3.34) to give the

correct speed and position feedback. This is particularly important if the

encoder is selected for speed feedback with Fb01 (Pr 0.71, 3.26). The

equivalent number of encoder lines per revolution (ELPR) is defined as

follows.:

The incremental (A/B) signal frequency should not exceed 500k Hz. If

Fb05 is changed the encoder is re-initialized.

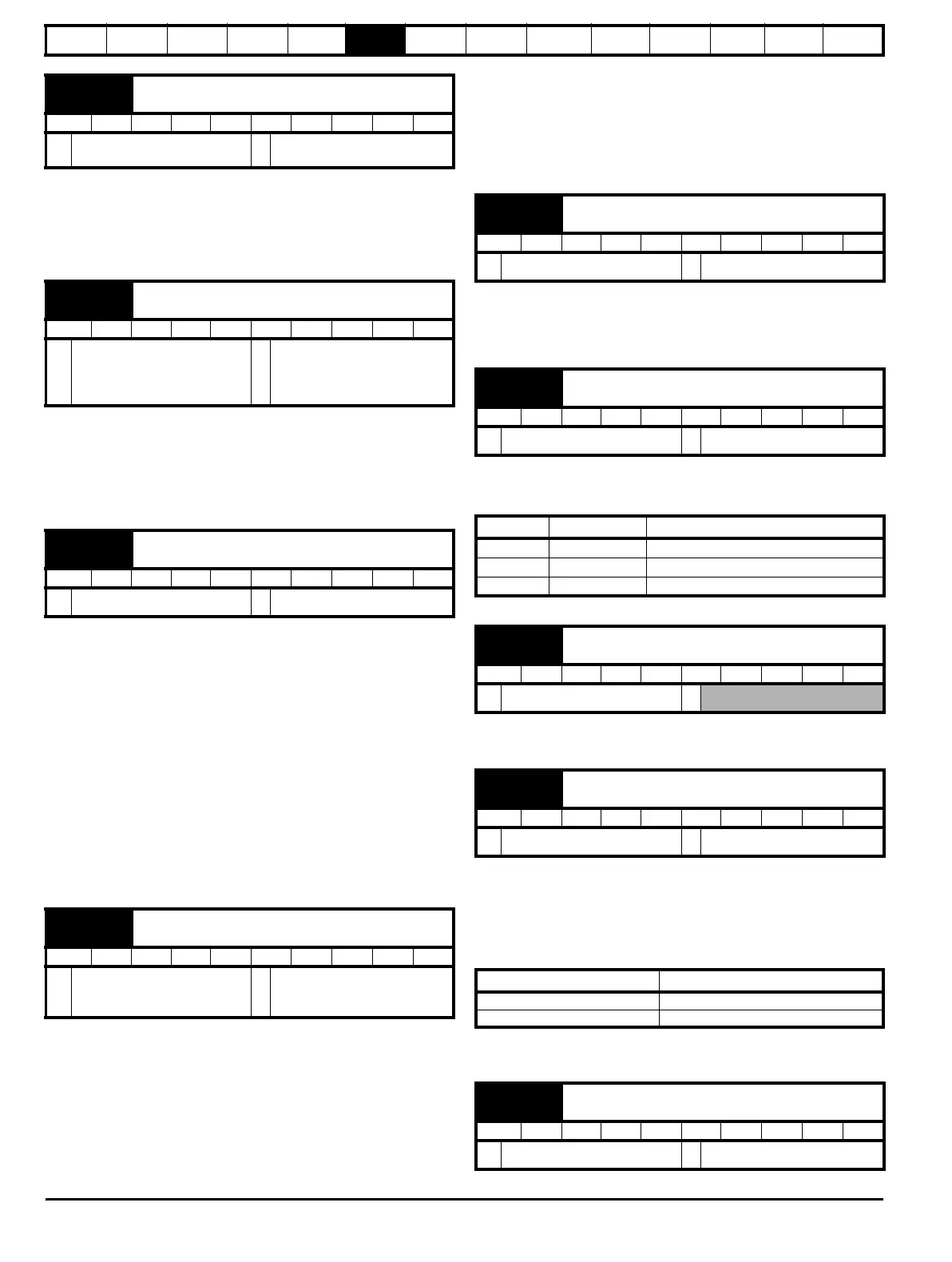

SP03

{0.63, 3.12}

(Kd1) Speed controller differential feedback gains

RW Uni US

0.00000 to 0.65535

(1/s / (rad/s))

0.00000

Si01

{0.61, 11.25}

Serial comms baud rate

RW Txt US

300 (0), 600 (1), 1200 (2),

2400 (3), 4800 (4), 9600 (5),

19200 (6), 38400 (7),

57600 (8)*, 115200 (9)*

19200 (6)

Si02

{0.67, 11.23}

Serial comms address

RW Uni US

0 to 247

1

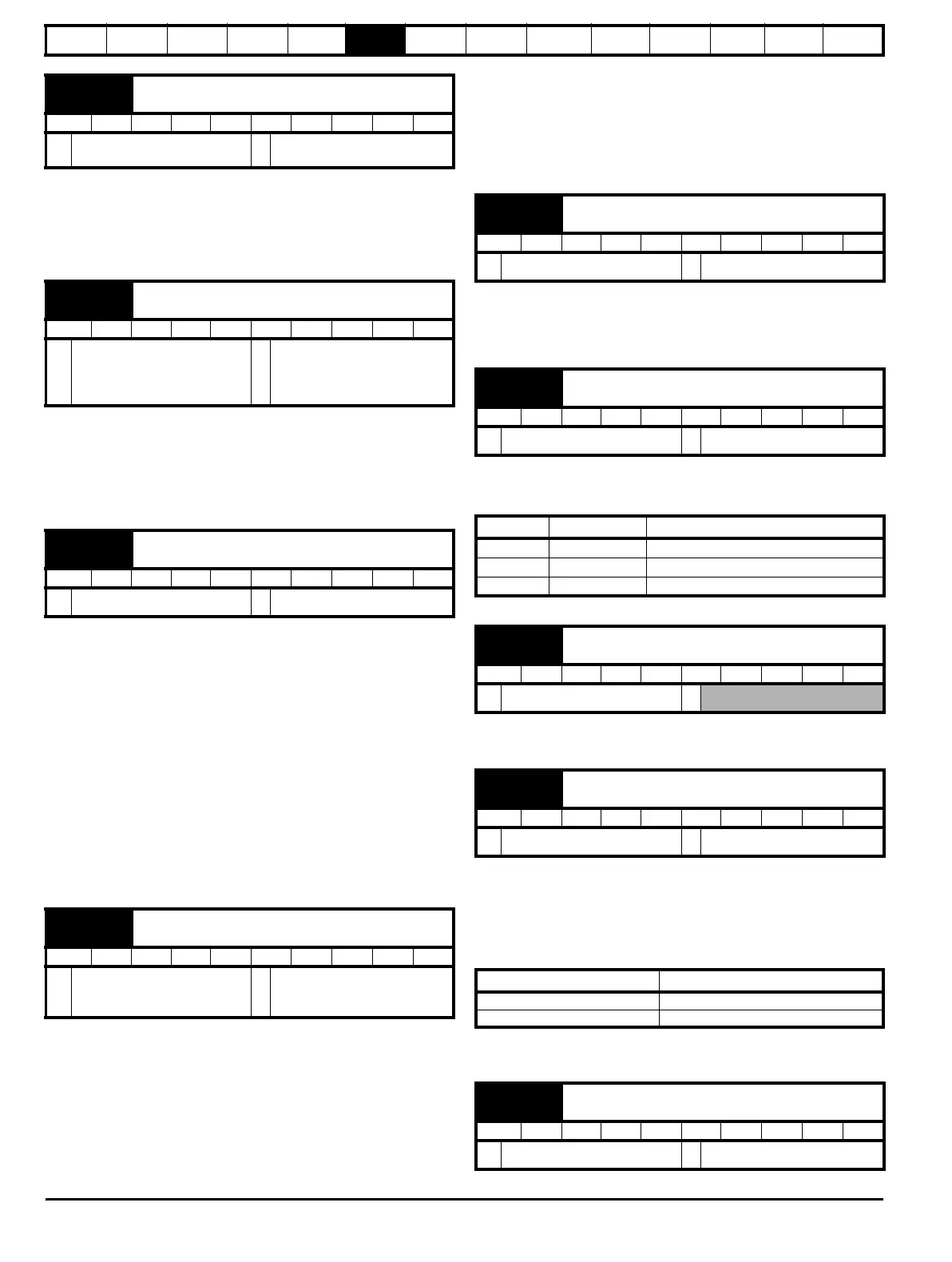

Fb01

{0.71, 3.26}

Speed feedback selector

RW Txt US

drv (0), Slot1 (1), Slot2 (2),

Slot3 (3), tACH (4), Est

SPEED (5)

Est SPEED (5)

Fb02

{0.72, 3.51}

Tachometer voltage rating

RW Uni US

0 to 300.00 V/1000 rpm

Eur: 60.00, USA: 50.00

Fb03

{0.73, 3.53}

Tachometer input mode

RW Txt US

DC (0), DC Filt (1), AC (2)

DC (0)

Value Text Action

0DC

DC tachometer

1DC Filt

DC tachometer with input filter

2AC

AC tachometer

Fb04

{0.74, 3.52}

Tachometer speed feedback

RO Bi FI NC PT

±SPEED_MAX rpm

Fb05

{0.75, 3.34}

Drive encoder lines per revolution

RW Uni US

1 to 50,000

1,024

Position feedback device ELPR

Ab number of lines per revolution

Fd, Fr number of lines per revolution / 2

Fb06

{0.76, 3.36}

Drive encoder supply voltage

RW Txt US

5V (0), 8V (1), 15V (2), 24V (3)

5V (0)

Loading...

Loading...