Liquisys M CPM223/253 Diagnostics and troubleshooting

Endress+Hauser 79

7 Diagnostics and troubleshooting

7.1 Troubleshooting instructions

The transmitter constantly monitors its functions itself. If an error occurs which the device

recognizes, this is indicated on the display. The error number is shown below the display of

the main measured value. If more than one error occurs, you can call these up with the

MINUS key.

Refer to the "System error messages" table for the possible error numbers and remedial

measures.

Should a malfunction occur without any transmitter error message, please refer to the

"Process-specific errors" or the "Device-specific errors" tables to localize and rectify the error.

These tables provide you with additional information on any spare parts required.

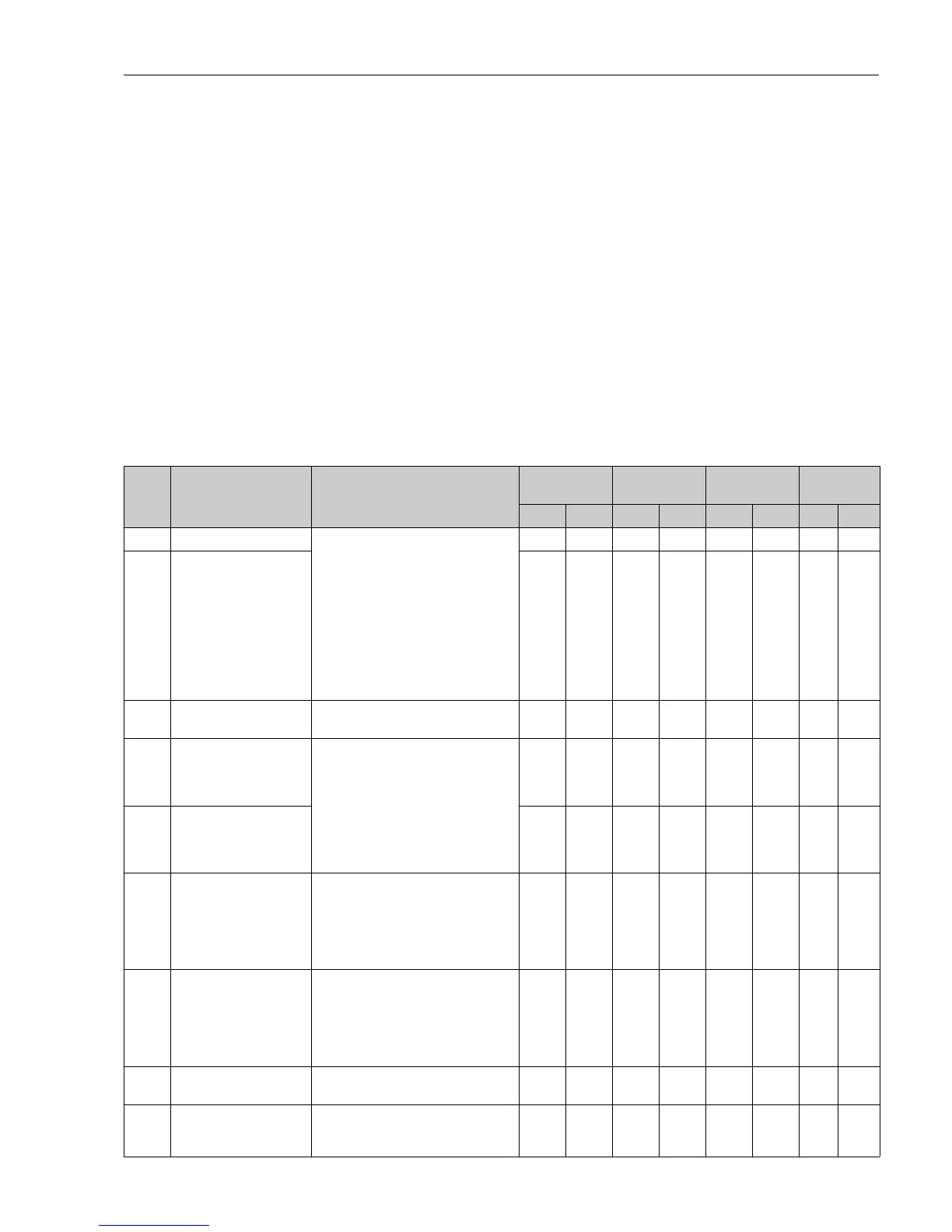

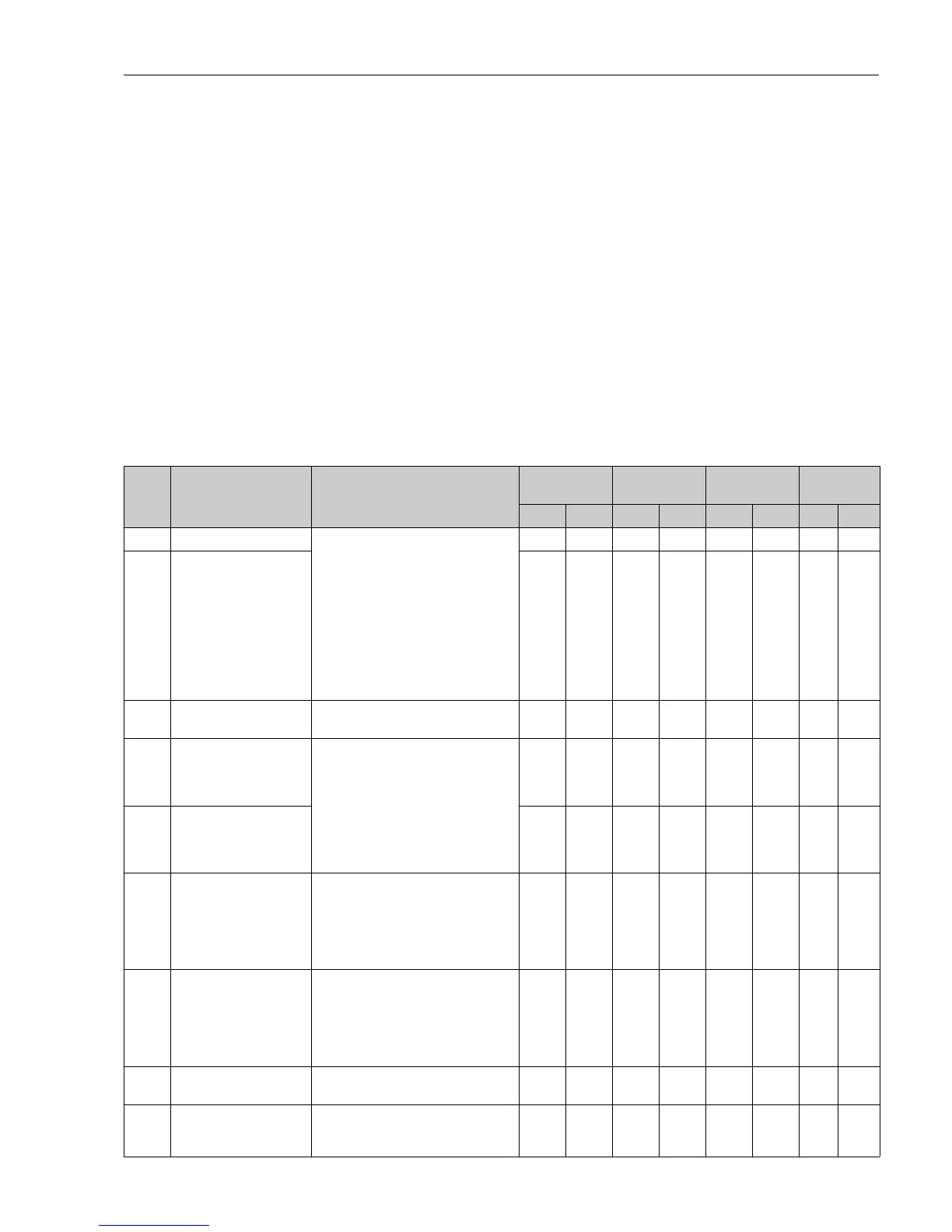

7.2 System error messages

You can display and select the error messages with the MINUS key.

Error

no.

Display Tests and/or remedial measures Alarm contact Error current Autom.

cleaning start

PROFIBUS

Status

Facty User Facty User Facty User pH Temp

E001 EEPROM memory error 1. Switch device off and then on again.

2. Load device software compatible

with the hardware (with optoscope,

see "Optoscope service tool" section).

3. Load measurement-parameter

specific device software.

4. If the error persists, send in the

device for repair to your local

Endress+Hauser subsidiary or

replace the device.

Yes No — —

1)

0C 0C

E002

Instrument not calibrated,

calibration data invalid, no

user data invalid

(EEPROM error),

instrument software not

suitable to hardware

(controller)

Yes No — —

1

0C 0C

E003 Download error

Invalid configuration. Repeat download,

check optoscope.

Yes No No 0C 0C

E004

Instrument software

version not compatible

with module hardware

version

Load software compatible with

hardware

Load measurement-parameter specific

device software.

Yes No No 0C 0C

E007

Transmitter malfunction,

instrument software not

compatible with

transmitter version

Yes No — —

1

0C 0C

E008

SCS alarm:

Glass electrode: glass

breakage

ISFET: leakage current >

400 nA

Check glass electrode for glass breakage

or hair-line cracks;

Inspect electrode plug-in head for

moisture and dry if necessary;

Check medium temperature.

Replace ISFET.

Yes No No 0C 80

E010

Temperature sensor

defective, not connected

or short-circuited

Check temperature sensor and

connections; check device and

measuring cable with temperature

simulator if necessary.

Check correct option selected in field

A5.

Yes No No 80 0C

E029

SCS reference electrode

warning

Error dedected during sensor self test.

Check sensor. If necessary, replace it.

Yes No — 0C 0C

E030

SCS reference electrode

warning

Check reference electrode for

contamination and damage; clean

electrode.

Yes No No 0C 80

Loading...

Loading...