Liquisys M CPM223/253 Diagnostics and troubleshooting

Endress+Hauser 83

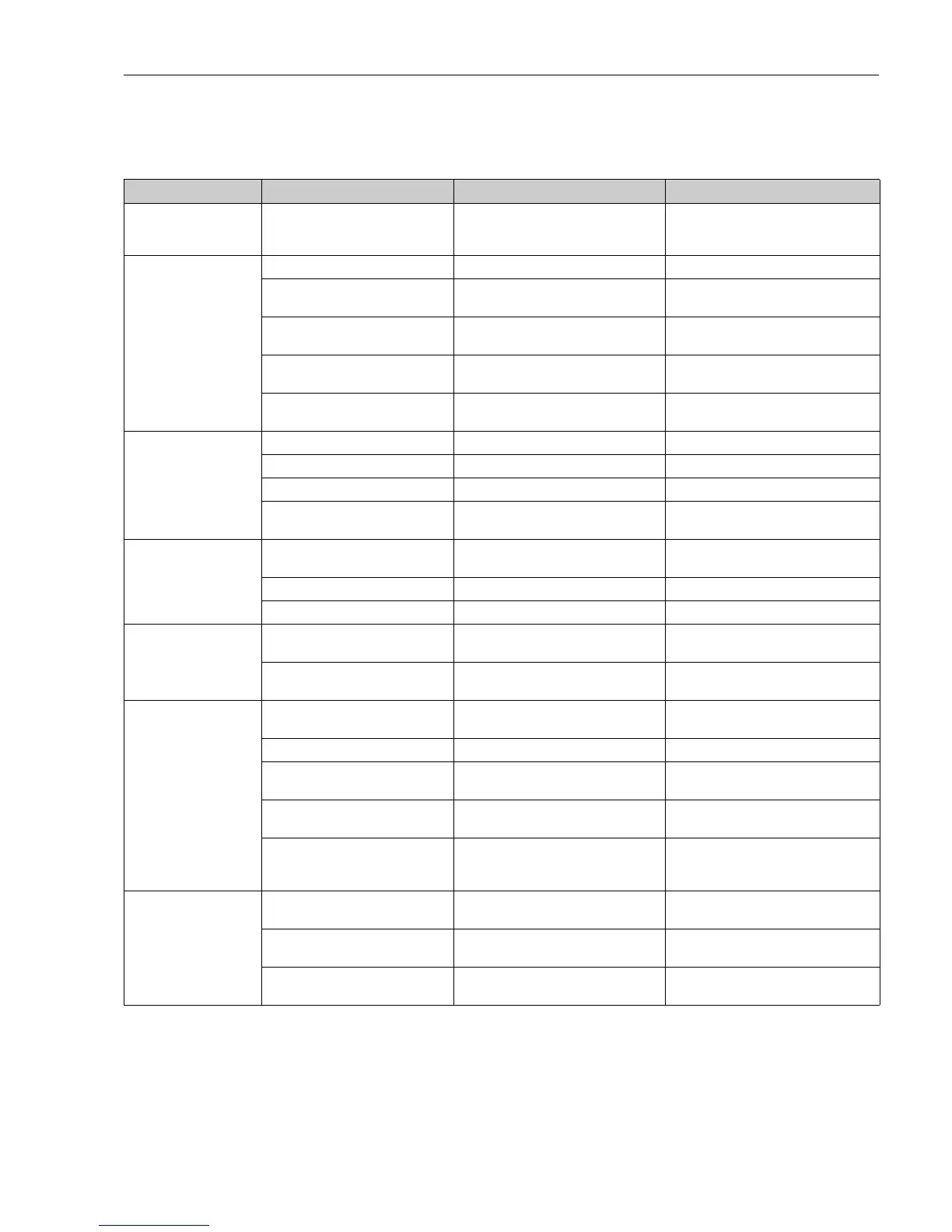

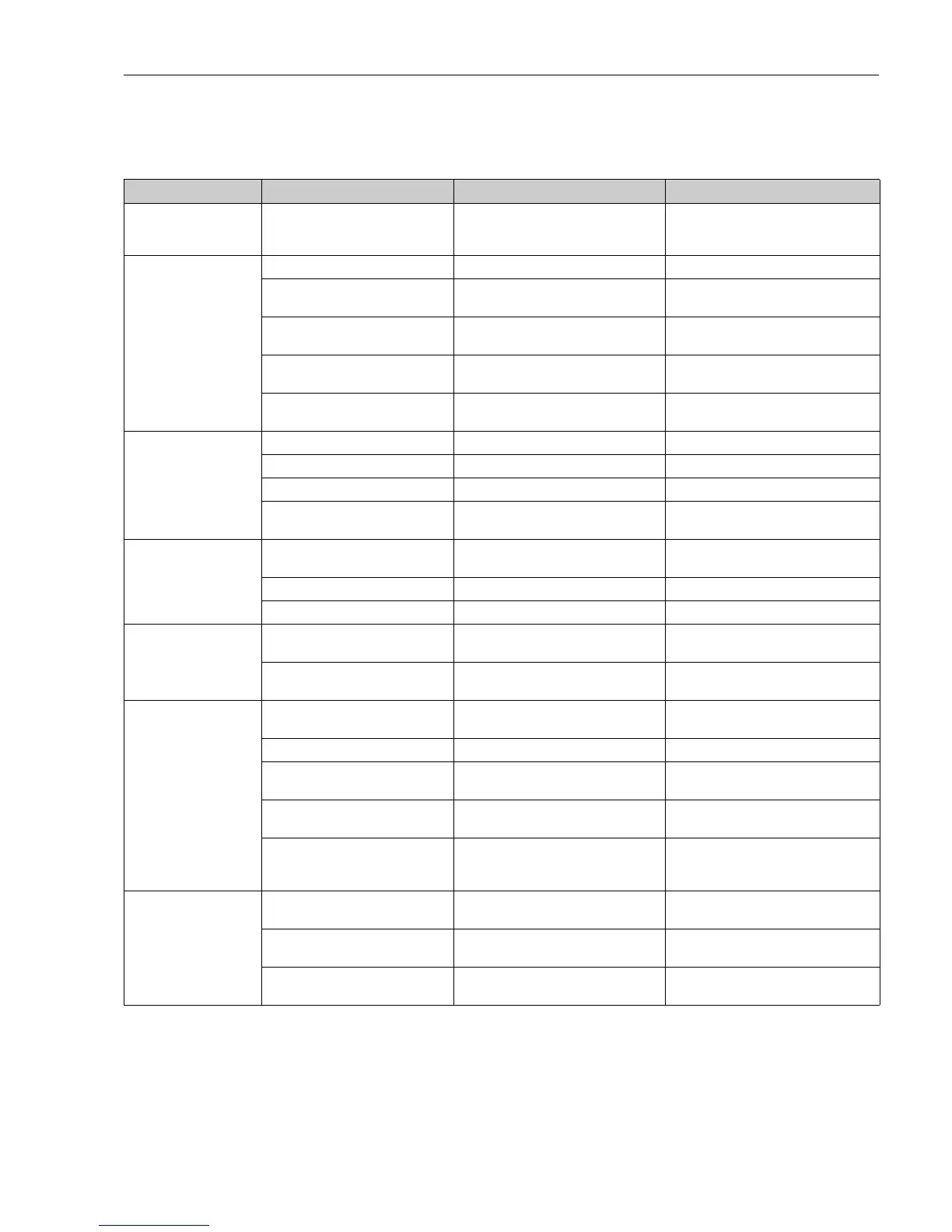

7.3 Process specific errors

Use the following table to localize and rectify any errors occurring.

Errors Possible cause Tests and/or remedial measures Tools, spare parts

Device cannot be

operated, display value

9999

Operation locked

Press CAL and MINUS keys

simultaneously

See "Function of keys" section.

Measuring chain zero-

point cannot be adjusted

Reference system toxified Test with new sensor pH/ORP sensor

Diaphragm clogged Clean or grind down diaphragm

HCl 3 %, use file (only file in one

direction)

Measuring line open

Short-circuit pH input on instrument

display pH 7

Sensor asymmetry voltage too high

Clean diaphragm or test with another

sensor

HCl 3 %, use file (only file in one

direction); sensor

Potential matching (PA/PM)

transmitter wrong medium

Asymm.: no PM or PM at PE

Symm.: PM connection mandatory

See "Electrode installation and measuring

cable connection" section

No or creeping change of

display

Sensor contaminated Clean sensor. See "Cleaning pH/ORP electrodes" section.

Sensor ageing Replace sensor. New sensor

Sensor defective (reference lead) Replace sensor. New sensor

No internal buffer

Check KCl supply (0.8 bar (11.6 psi)

above medium pressure).

KCl (CPY 4-x)

Measuring chain slope

not adjustable/slope too

small

No high-impedance connection

(moisture, dirt)

Check cable, plug connector and junction

boxes.

pH simulator, insulation, see "Checking

the connecting lines and boxes" section

Device input defective Check device directly. pH simulator

Sensor ageing Renew sensor. pH sensor

Measuring chain slope

not adjustable/no slope

Hair-line crack in the glass

membrane

Renew sensor. pH sensor

No high-impedance connection

(moisture, dirt)

Check cable, plug connector and junction

boxes.

pH simulator, insulation, see "Checking

the connecting lines and boxes" section

Permanent, incorrect

measured value

Sensor not immersing or protection

cap not removed

Check installation position, remove

protection cap.

Air cushion in assembly Check assembly and orientation.

Ground connection at or in device

Perform test measurement in insulated

vessel, poss. with buffer solution.

Plastic vessel, buffer solutions

Hair-line crack in the glass

membrane

Renew sensor. pH sensor

Impermissible device operating

status (no reaction to key actuation)

Switch device off and then on again.

EMC problem: if this persists, check the

grounding, screens and line routing or

have checked by Endress+Hauser Service.

Incorrect temperature

value

Incorrect sensor connection Check connections using wiring diagram.

Wiring diagram "Electrical connection"

section

Measuring cable defective

Check cables for interruptions/short-

circuit/shunt.

Ohmmeter

Incorrect sensor type

Set type of temperature sensor at the

device (field B1).

Glass electrode: Pt 100

ISFET: Pt 1000

Loading...

Loading...