Diagnostics and troubleshooting Liquisys M CPM223/253

84 Endress+Hauser

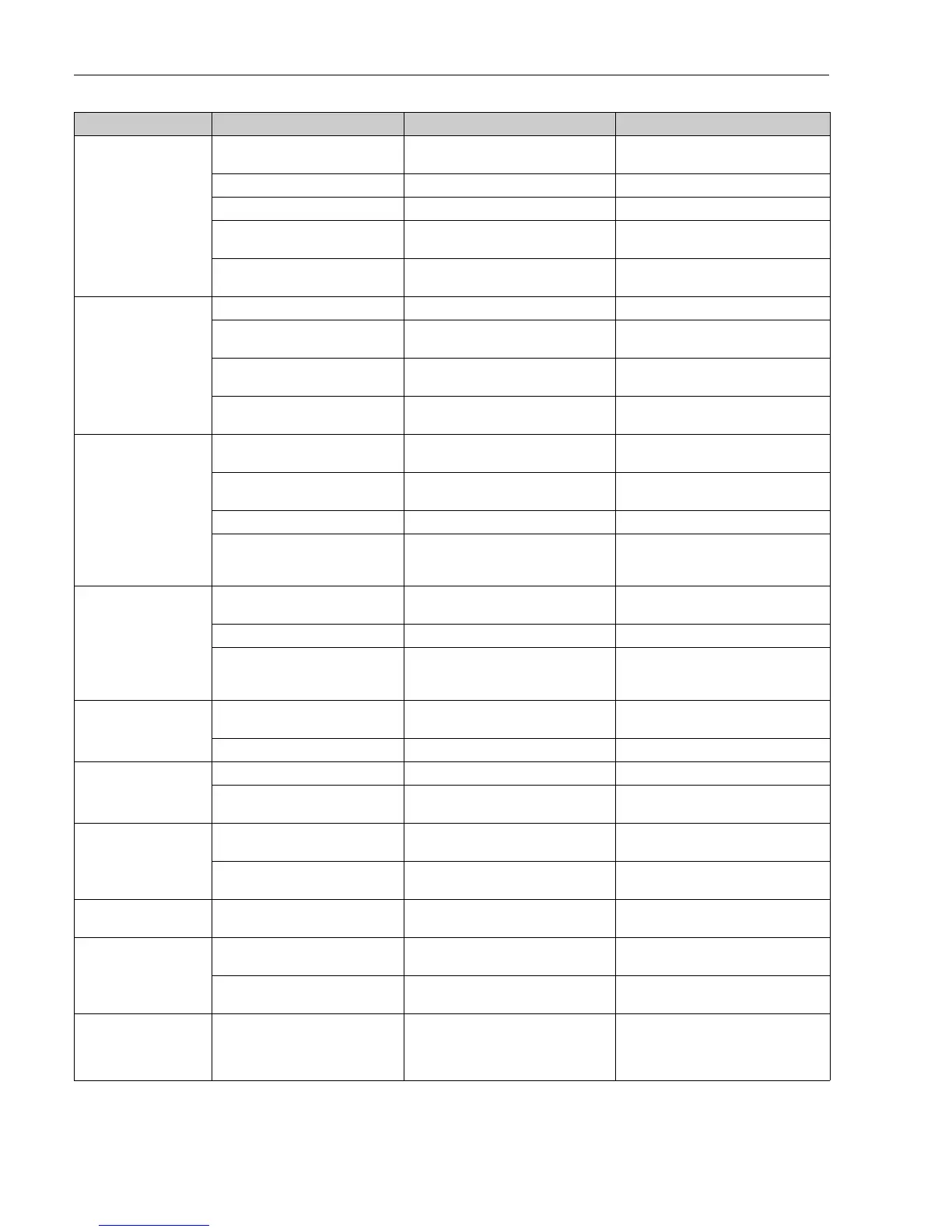

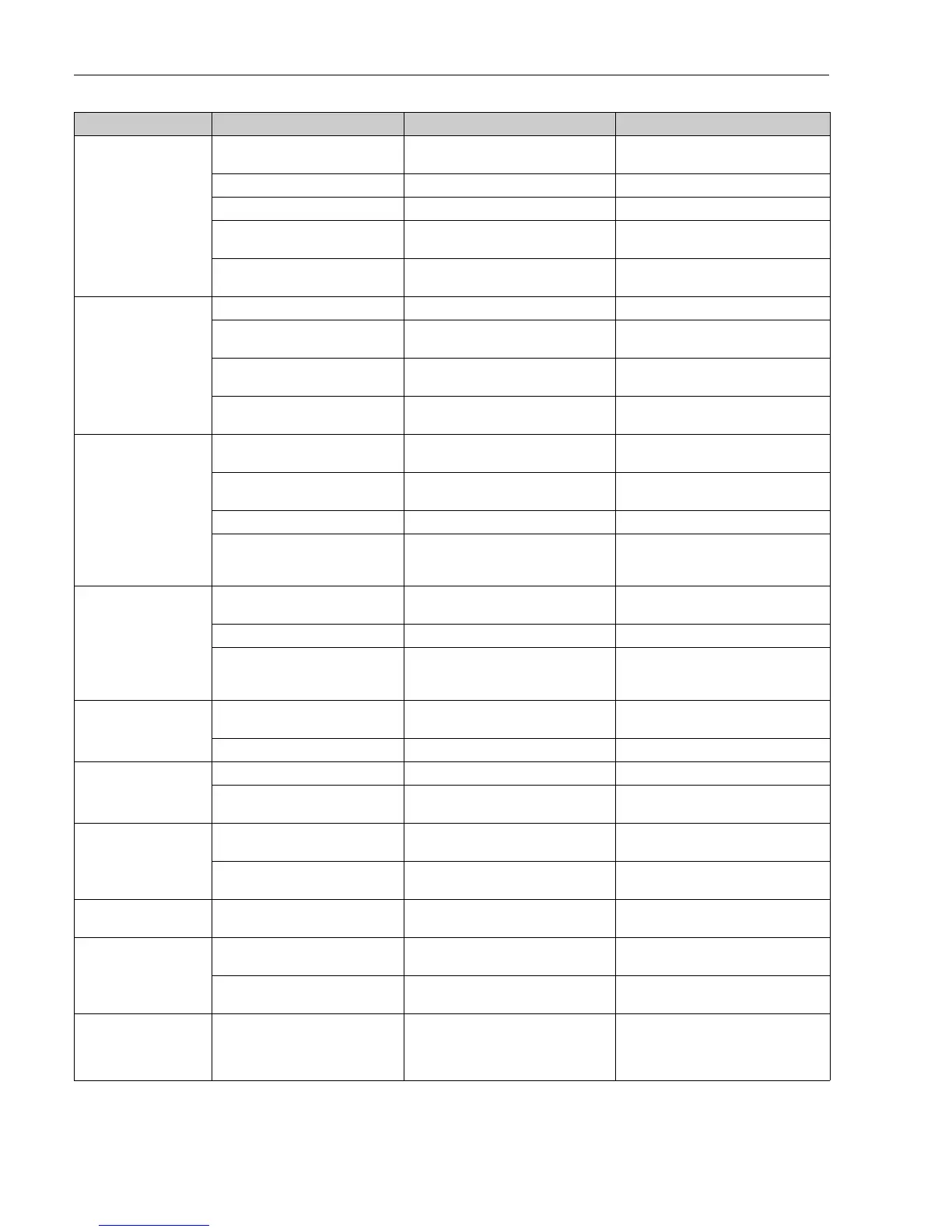

pH value in process wrong

No/incorrect temperature

compensation

ATC: activate function.

MTC: adjust process temperature.

Conductivity of medium too low Select pH sensor with liquid KCl. e.g. Ceraliquid CPS41

Flow too high Reduce flow or measure in a bypass.

Potential in medium

Poss. ground with or at PM pin

(connection PM/PE).

Problem occurs particularly in plastic

lines.

Sensor contaminated or assigned

Clean sensor (see "Cleaning pH/ORP

sensors" section).

For heavily contaminated media:

Use spray cleaning.

Measured value

fluctuations

Interference on measuring cable Connect cable as per wiring diagram. See "Electrical connection" section.

Interference on signal output line

Check line routing, lay line separately if

necessary.

Signal output and measuring input lines

Interference potential in medium Measure symmetrically (with PML).

Poss. ground medium with PM/PE

connection.

No potential matching (PA/PM) for

symmetrical input

Connect PM pin in assembly with devices

PA/PM.

Controller/limit contact

does not work

Controller switched off Activate controller.

See "Relay contact configuration" section

or fields R2xx.

Controller in operating mode

"Manual/off"

Select "Auto" or "Manual on" mode. Keyboard, REL key

Pick-up delay set too long Switch off or shorten pick-up delay time. See fields R2xx.

"Hold" function active

“Auto hold” for calibration,

“Hold” input activated,

“Hold” active via keyboard.

See fields S2 to S4.

Controller/limit contact

works constantly

Controller in operating mode

"Manual/on"

Set controller to "Manual/off" or "Auto". Keyboard, REL and AUTO keys

Drop-out delay set too long Reduce drop-out delay time. See fields R2xx.

Control circuit interrupted

Check measured value, current output or

relay contacts, adjusters, chemical

supply.

No pH/mV current output

signal

Line open or short-circuited

Disconnect line and measure directly at

the device.

mA meter 0–20 mA DC

Output defective See "Diagnosis" section.

Fixed pH/mV current

output signal

Current simulation active Switch off simulation. See field O2.

Impermissible processor system

operating status

Switch device off and then on again.

EMC problem: if it persists, check the

installation.

Incorrect current output

signal

Incorrect current assignment

Check current assignment:

0–20 mA or 4–20 mA?

Field O211

Overall burden in the current loop

too high (> 500 )

Disconnect output and measure directly

at the device.

mA meter for 0–20 mA DC

Current output table is

not accepted

Value distance too small Select practical distances.

No temperature output

signal

Device does not have a second

current output

Check version using nameplate, if

necessary, replace module LSCH-x1.

Module LSCH-x2,

See "Spare parts" section.

Device with PROFIBUS-PA

PA device does not have any current

output!

Chemoclean function not

available

No relay module (LSR1-x) installed

or only LSR1-2 available

Install LSR1-4 module.

The Chemoclean is enabled using the

release code supplied by E+H in the

Chemoclean retrofit kit.

Module LSR1-4, see "Spare parts" section.

Errors Possible cause Tests and/or remedial measures Tools, spare parts

Loading...

Loading...