Micropilot FMR56, FMR57

Endress+Hauser 7

Function and system design

Measuring principle

The Micropilot is a "downward-looking" measuring system, operating based on the time-of-flight

method (ToF). It measures the distance from the reference point R (process connection of the

measuring device) to the product surface. Radar pulses are emitted by an antenna, reflected off the

product surface and received again by the radar system.

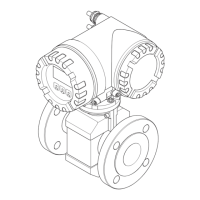

A0017872

1 Setup parameters of the Micropilot

R Reference point of the measurement (lower edge of the flange or threaded connection)

E Empty calibration ( = zero)

F Full calibration (= span)

D Measured distance

L Level (L = E - D)

Input

The reflected radar impulses are received by the antenna and transmitted into the electronics. A

microprocessor evaluates the signals and identifies the level echo caused by the reflection of the

radar pulses at the product surface. The unambiguous signal identification is accomplished by the

PulseMaster® eXact software together with the Multi-echo tracking algorithms, based on over 30

years of experience with time-of-flight technology.

The distance D to the product surface is proportional to the time of flight t of the impulse:

D = c · t/2,

with c being the speed of light.

Based on the known empty distance E, the level L is calculated:

L = E – D

The Micropilot is equipped with functions to suppress interference echoes. The user can activate

these functions. Together with the multi-echo tracking algorithms they ensure that interference

echoes, e.g. from from internal fixtures and struts, are not interpreted as level echoes.

Loading...

Loading...