Maintenance and Troubleshooting

Hardware Installation and Maintenance Manual B

–27

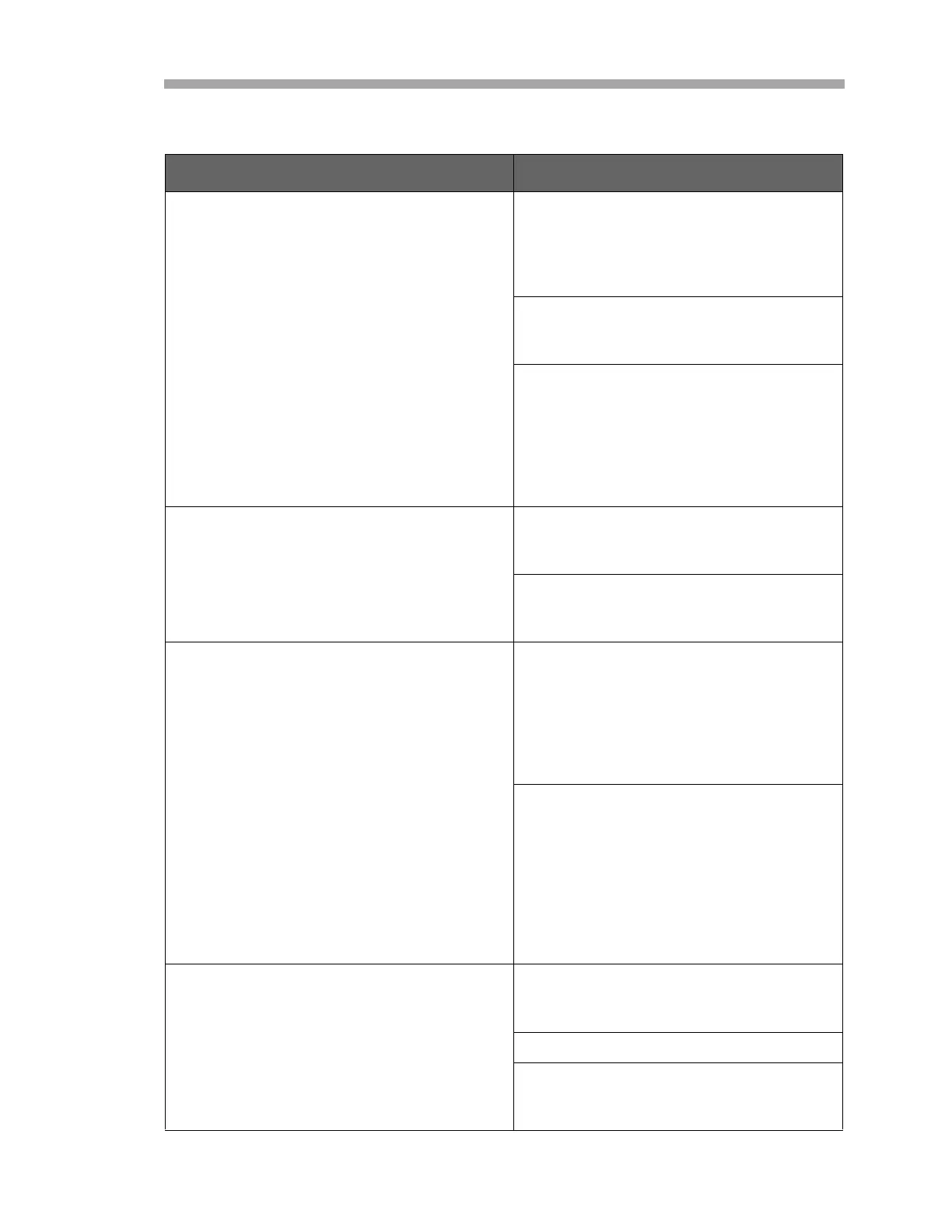

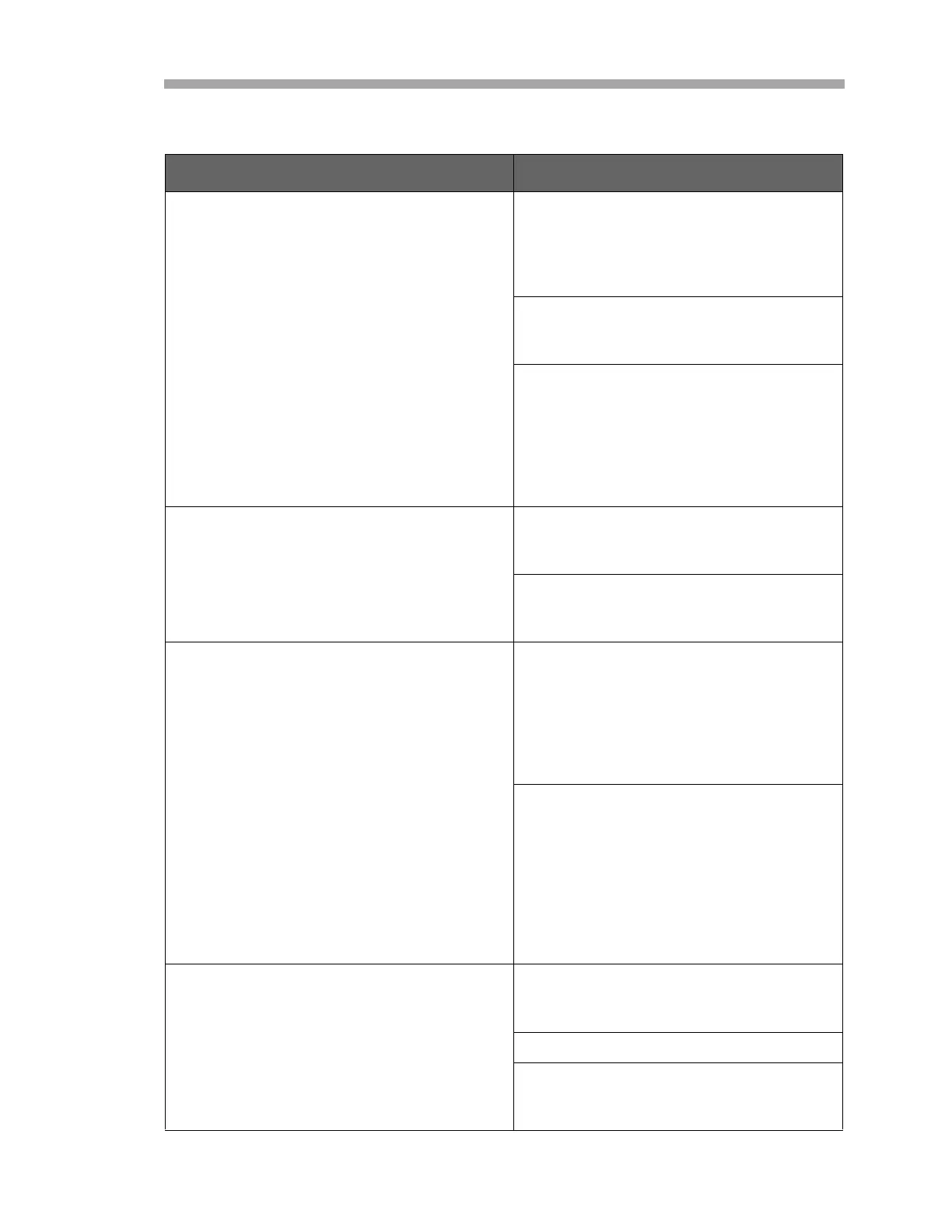

Table B-1 Potential analyzer issues and solutions (Continued)

Symptom Response

Laser Power Low Alrm Capture diagnostic data and send the

file to SpectraSensors (see “To read

diagnostic data with

HyperTerminal” in the Firmware

Manual).

Possible alignment problem. Contact

Service for service information. Refer

to “Service Contact” on page B-31.

Possible mirror contamination issue.

Contact Service for service information.

Refer to “Service Contact” on page

B-31. If advised to do so, clean the

mirrors by following the instructions

under “To clean the mirrors” on

page B-6.

Pressure Low Alarm or Pressure

High Alarm

Check that the actual pressure in the

measurement cell is within

specification.

Check the connector on the pressure

sensor. Check the pressure connector

on the backplane board.

Temp Low Alarm or Temp High

Alarm

Check that the actual temperature in

the measurement cell is within

specification. For systems with a

heated enclosure, check that the

temperature in the measurement cell is

within +/- 5

C of the specified

enclosure temperature.

Check the connector on the cell

temperature sensor. Check the

temperature connector on the

backplane board. (NOTE: A

temperature reading greater than

150 °C indicates a short circuit on the

temperature sensor leads; a reading of

less than –30 °C indicates an open

circuit).

Front panel display is not lit and no

characters appear

Check for correct voltage on terminal

block input. Observe polarity on DC

powered units.

Check for correct voltage after fuses.

Check for 5 VDC on red wires, 12 VDC

on yellow wires, and 24 VDC on orange

wires from the power supply.

Loading...

Loading...