SS2100i-1 Analyzer

3–6 4900002260 rev. B 12-20-17

smeared with a suitable grease (e.g., Silicon Grease GS9) to prevent corrosion

and to assist weather-proofing.

Bolts, screws and similar parts, depending on the type of protection required,

shall only be replaced by similar parts in accordance with the manufacturer’s

design.

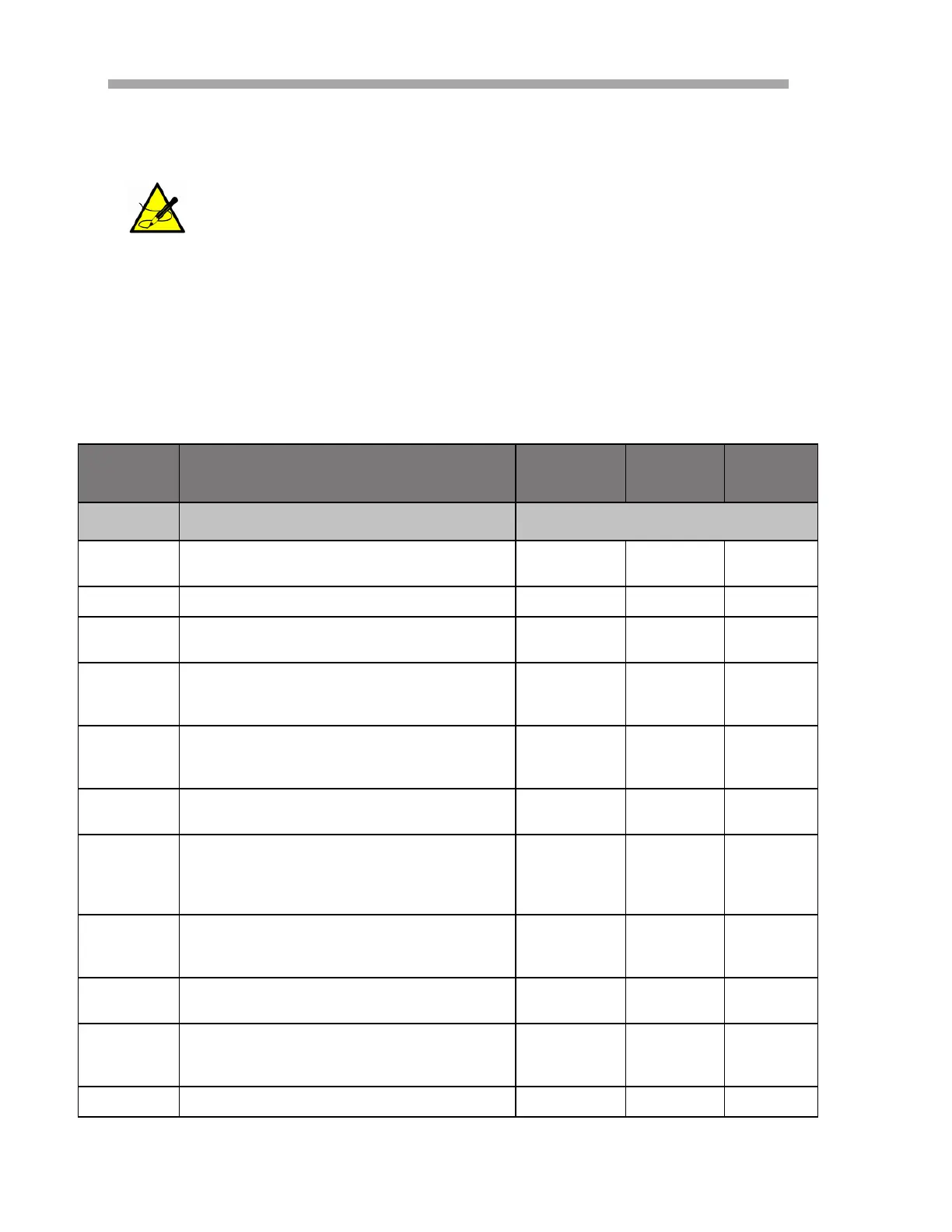

Refer to Table 3–1 for the inspection schedule for Ex “d”, Ex “e”, Ex “n”

equipment.

Only non-metallic scrapers and non-corrosive cleaning fluids may

be used to clean flanges.

Table 3–1 Inspection Schedule for Ex “d”, Ex “e”, Ex “n”

Items to

Check

Description Ex “d” Ex “e” Ex “n”

General (All Equipment) Grade of Inspection

1 Equipment is appropriate to the EPL/zone

requirements of the location

XXX

2 Equipment group is correct

XXX

3 Equipment temperature class is correct (only

for gas)

XXX

4 Degree of protection (IP grade) of equipment

is appropriate for the level of protection/

group/conductivity

XXX

5 Enclosure, glass parts and glass-to-metal

sealing gaskets and/or compounds are satis-

factory

XXX

6 There is no damage or unauthorized modifi-

cations

XXX

7 Bolts, cable entry devices (direct and indi-

rect) and blanking elements are of the cor-

rect type and are complete and tight -

physical check

XXX

8 Joint surfaces are clean and undamaged.

Gaskets, if any, are satisfactory and posi-

tioned correctly

X

9 Condition of enclosure gaskets are satisfac-

tory

XXX

10 There is no evidence of ingress of water or

dust in the enclosure in accordance with IP

rating

XXX

11 Electrical connections are tight

XX

Loading...

Loading...