Installation

5.4 Installer/service notes for the use of gas oil with bio blends up to 10% where gas oil use is permitted by the

appliance manufacturer

• During the burner installation, check that the gas

oil and biofuel blends are in accordance with EOGB’s spec-

ications (please refer to the chapters “Technical Data” and

“Guidance for the use of biofuel blends up to 10%” within

the burner technical manual).

• If a bio blend is in use the installer must seek

information from the end user that their fuel supplier can

evidence that the blends of fuel conform to the relevant

standards.

• Check that the materials used in the construction

of the oil tank and ancillary equipment are suitable for

biofuels, If not these must be upgraded or replaced with

bio compatible parts. (Please contact EOGB for more info

on other biofuel compliant products)

• Particular attention should be given to the oil stor-

age tank and supply to the burner. It is recommended that

existing oil storage tanks are cleaned, inspected and any

traces of water are removed BEFORE biofuel is introduced

(contact the tank manufacturer or oil supplier for further

advice). If these recommendations are not respected this

will increase the risk of contamination and possible equip-

ment failure.

• In line oil lters should be replaced making sure

that they are bio compatible. It is recommended that a

good quality bio compatible oil lter at the tank and a

secondary 60 micron lter are used to protect the burner

pump and nozzle from contamination.

• The burner hydraulic components and exible oil

lines must be suitable for biofuel use (check with EOGB if

in doubt). EOGB have carefully chosen the specication

of the bio compatible components including the exible

oil lines to protect the pump, safety value and nozzle.

The EOGB warranty is dependent upon the use of EOGB

recommended components including the oil lines, being

used. The burner must be commissioned and combustion

parameters set to appliance manufacturer’s recommenda-

tions.

• Regularly check visually for any signs of oil leakage

from seals, gaskets and hoses.

• It is strongly recommended that with Biofuel use,

oil lters are inspected and replaced every 4 months. More

regularly where contamination is experienced.

• During extended periods of non operation and/or

where burners are using oil as a standby fuel, it is strongly

recommended that the burner is put into operation for

shorts periods at least every three months.

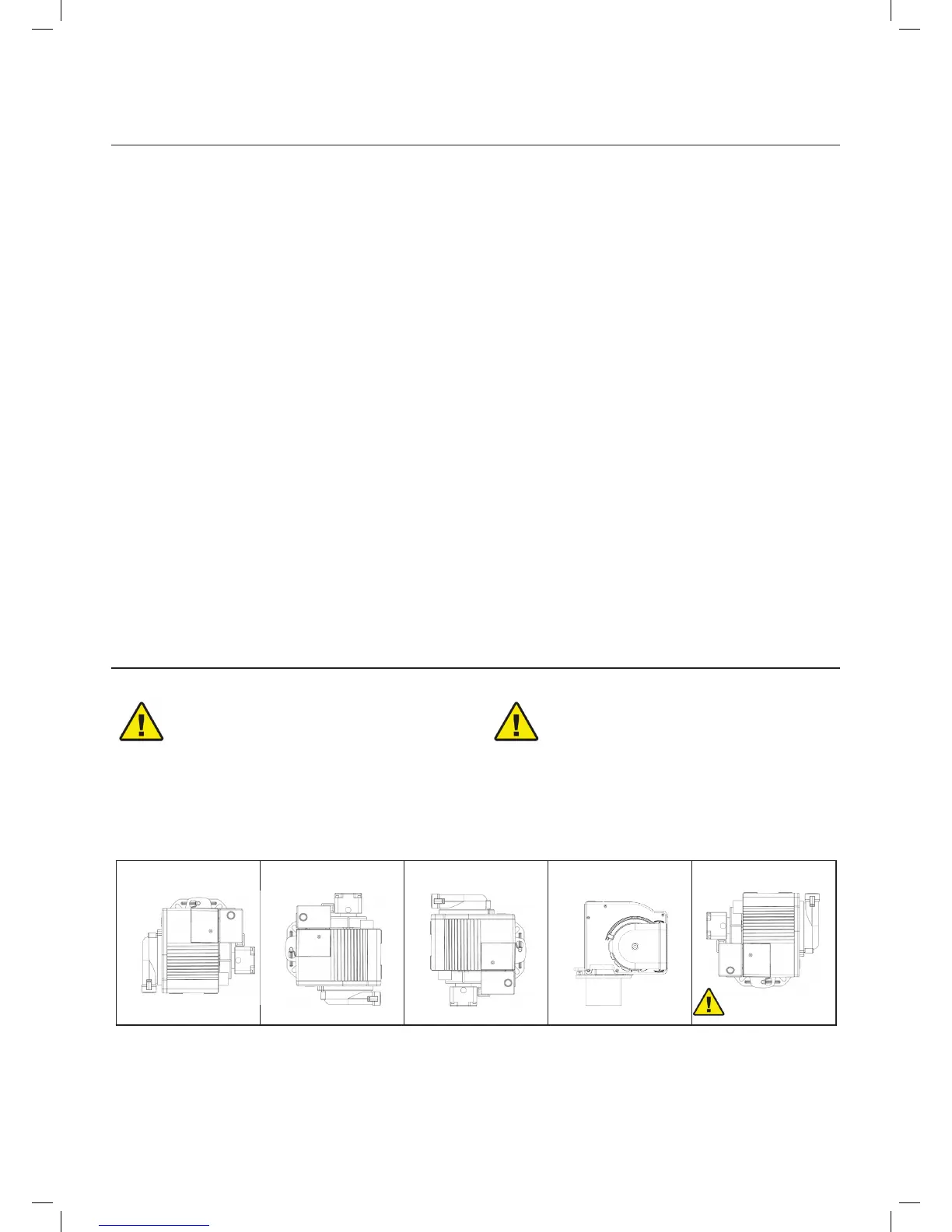

5.5 Working position

The burner is designed to operate only in the

positions 1, 2, 3 and 4 (Fig. 5).

Installation 1, 2 and 3 is preferable, as it is the

only one that allows performing maintenance

operations as described in this manual.

Installation 4 allows for working operations but

may incur maintenance issues as some adjusta-

ble settings may be obstructed

Any other position could compromise the correct op-

eration of the appliance. Installation 5 is forbidden for

safety reasons, unless the burner has been supplied

to suit an upside down ring position or the burner has

been modied so the oil pump has been rotated 90

degrees to prevent the solenoid coil ring in a down-

wards orientation (please seek further assistance from

EOGB on this modication.)

WARNING

CAUTION

Fig. 5

2

3

4 5

1

See note above

CAUTION

Loading...

Loading...