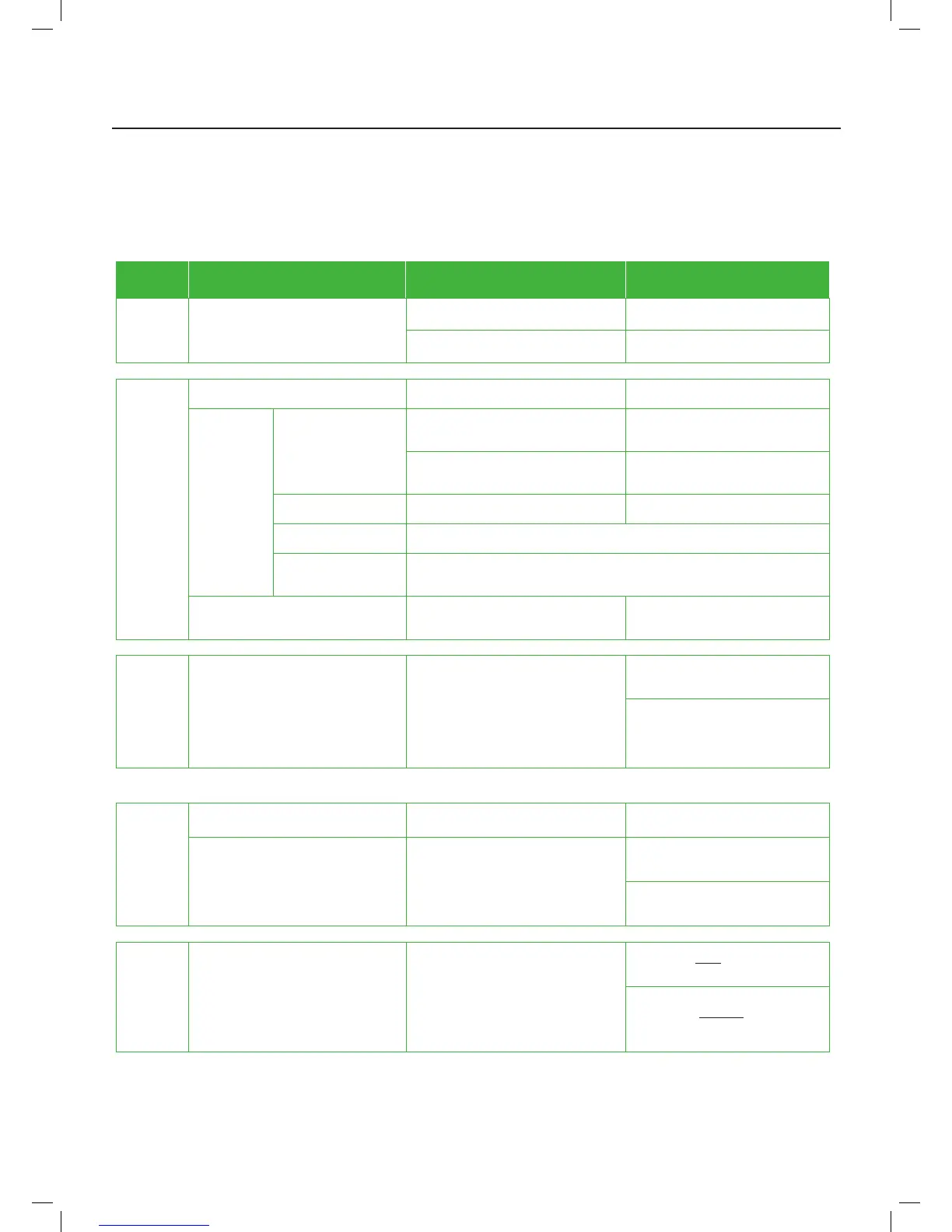

Fault Probable cause Useful test Solution

The burner

will not start

Lack of Voltage

Is there 230v onto terminal 9 of the control

box?

Replace control box

If there is no voltage onto terminal 9 then

there is an external fault

Check thermostats, switches, fuses etc to

trace fault

The burner

starts but no

ame is pres-

ent and the

burner goes

to lockout

No fuel to burner Check if there is oil present at the pump inlet Check fuel tank, valves, etc for problems

No fuel to the

nozzle

No voltage to solenoid

coil

Cover photocell. If burner res up ok then

photocell must be detecting a light source

during pre-purge

Identify source, spark, etc and remedy

If there is still no ame disconnect photocell.

If now ok then cell must be faulty.

Replace photocell

Voltage to coil but not

energizing

Test to ensure the coil measures a resistance

of between 2-3 kohms

Replace coil

Coil energized but no oil

at pump outlet

Check valve opening. Replace if necessary

Oil at pump outlet but

none through the nozzle

Replace nozzle, or check line for blockage

No Spark

Check electrodes, HT leads and voltage to

transformer. If all ok then transformer is faulty.

Replace transformer

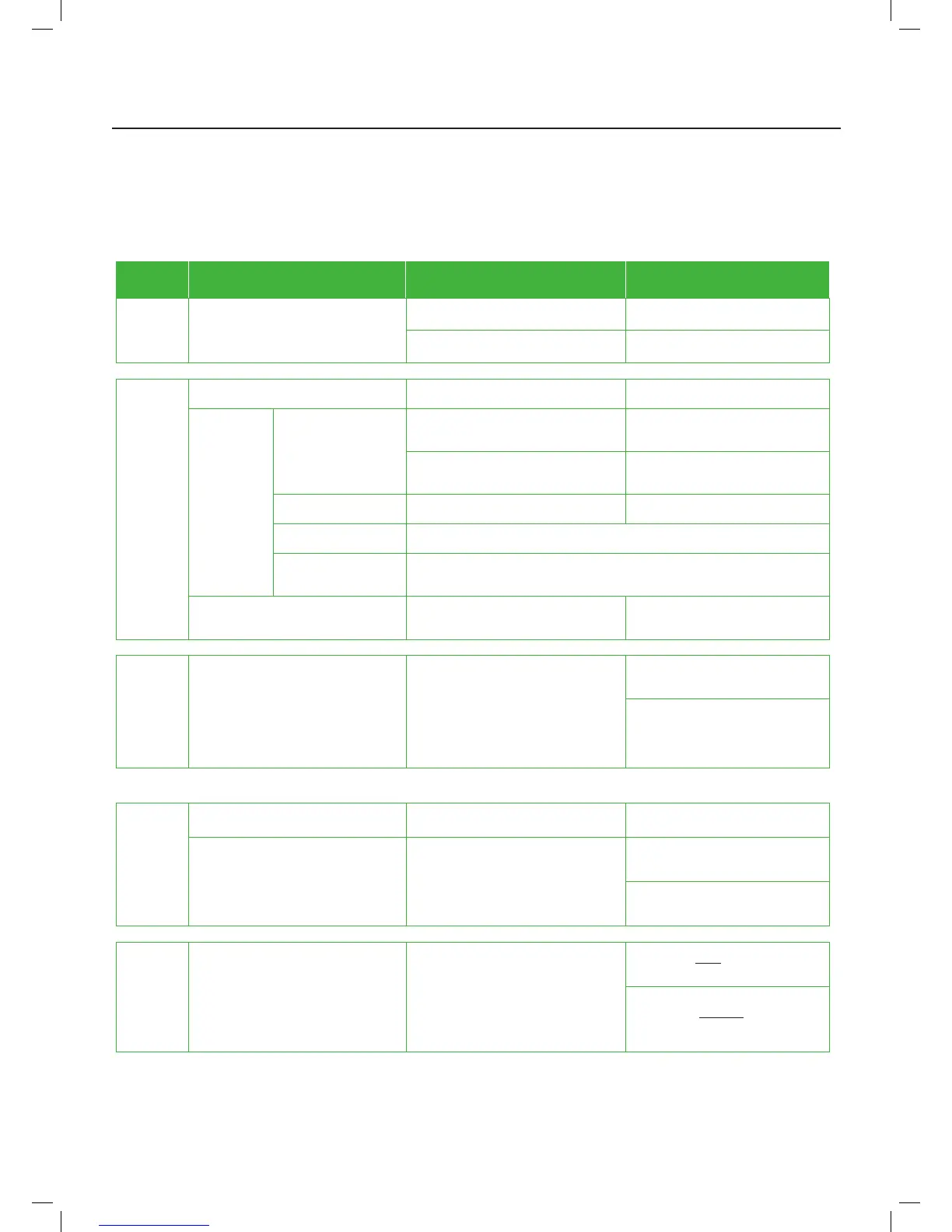

The burner

starts, estab-

lishes a ame

and locks out

aer 10 secs

Flame recognition (photocell not seeing

ame)

Remove photocell and ensure that it is

covered and not exposed to any light, reset

burner and once the burner establishes

a ame (aer about 12 Secs) expose the

photocell to light

If the burner still goes to lockout, then

check photocell/photocell lead/ control

box

If the burner continues to run, check that

photocell is not obstructed from seeing

the ame, Check combustion settings,

consult EOGB for further information

The burner

starts, and

a ame is

established

instantly and

the burner

goes to

lockout aer

20 secs

Solenoid stem is letting by Disconnect solenoid lead and re-test.

If the burner still establishes a ame then

replace solenoid stem/pump

Solenoid stem is being energised before it

should be

Disconnect any external wiring from terminal

B4 and test solenoid lead for 230v

If voltage disappears when external wir-

ing is removed the fault will be external,

investigate boiler wiring

If voltage remains then replace control

box

The burner

starts, no

ame is

established

and the

burner goes

to lockout

aer 20secs

Flame recognition/stray light Disconnect the photocell/lead, and retest

If the burner does re up for 10 secs the

replace photocell/lead

If the burner does not re the replace

control box

Maintenance / Service

9.3 Fault nding

Below is a list of some scenarios that may lead to a failure causing the burner to go into lockout mode. There are also

some relevant tests and solutions to hopefully overcome any problem that may occur.

Push the reset button to re-start the burner. If the burner then functions correctly the control has simply responded to a

temporary fault. If the burner still fails then a further investigation will be required to correct any fault.

Loading...

Loading...