Oil Supply

6 Oil Pump

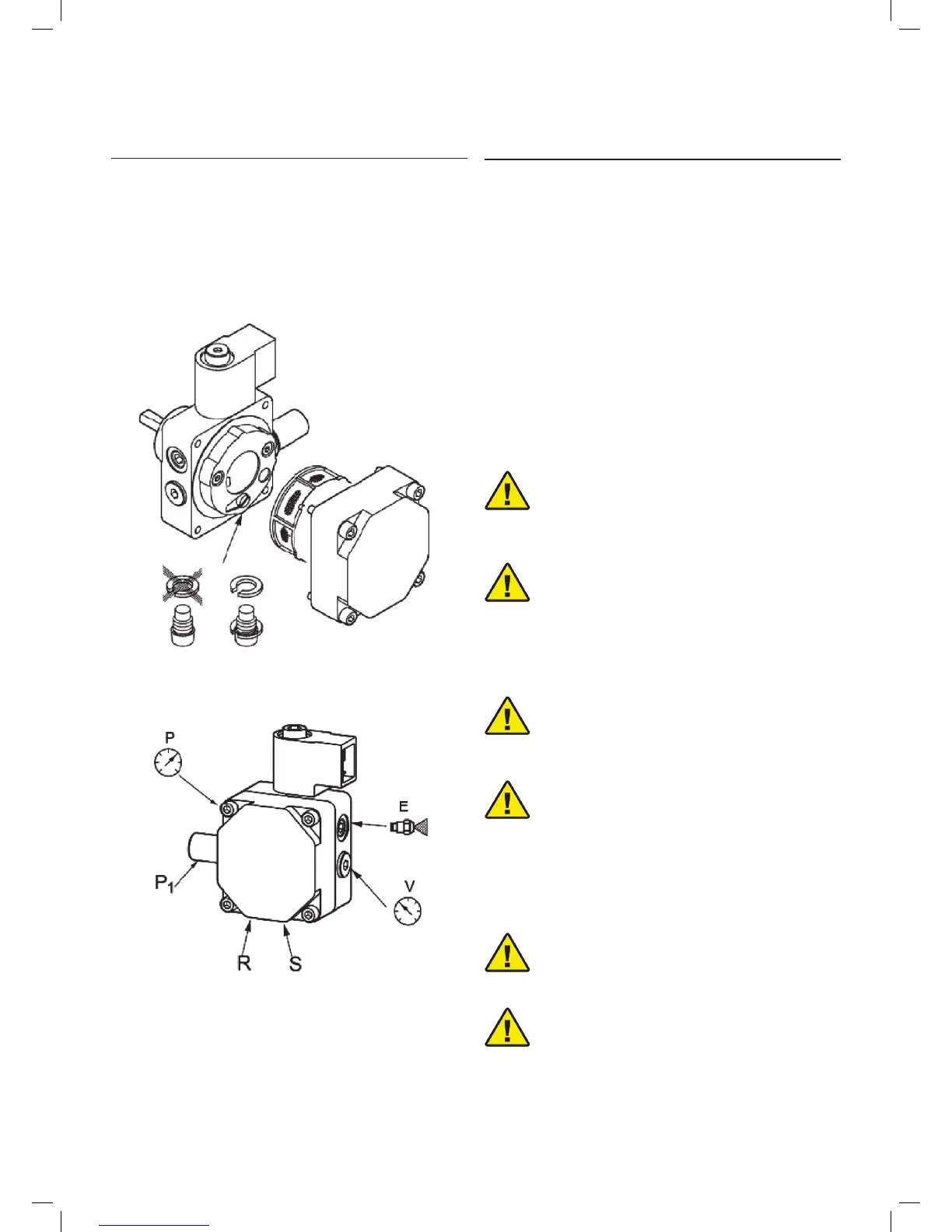

The pump is supplied and set as standard (unless specied

otherwise) as a one pipe conguration.

In order to obtain a two pipe conguration it is necessary

to remove the horseshoe washer from the BFP11 oil pump

(See Fig. 11). Aer removal, an additional oil exible will

have to be tted yo the return port (additional oil exible

not supplied).

Fig. 11

Washer removed

= 2 pipe

Washer tted

= 1 pipe

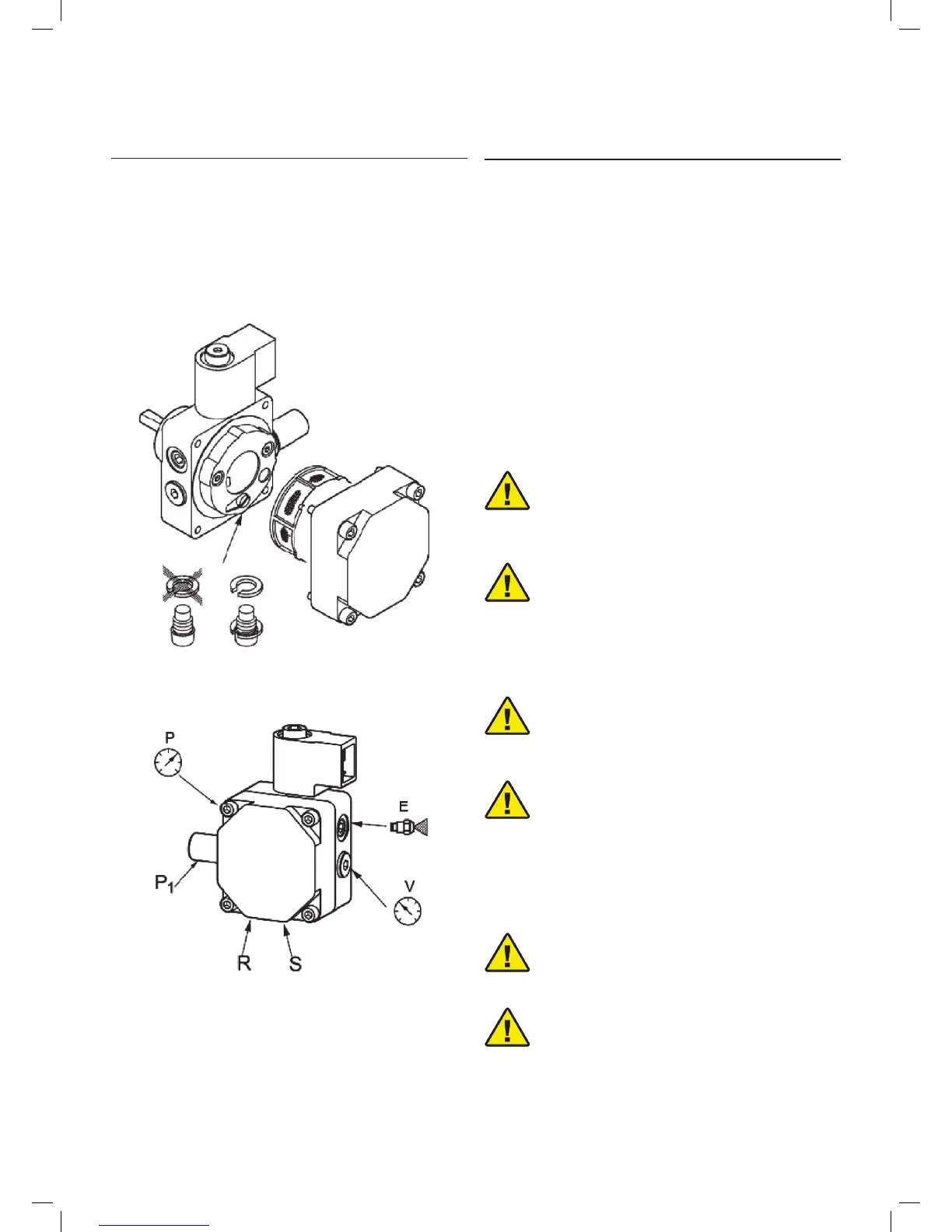

P - Pressure gauge port 1/8”

P1 - Pressure adjuster

E - Nozzle outlet 1/8”

V - Vacuum gauge port 1/8”

R - Return outlet port 1/4”

S - Suction inlet port 1/4”

Key (Fig. 12)

Fig. 12

Where gas oil containing biodiesel is in use, it is

recommended to avoid over oxygenation of the

blended fuels.

Where at all possible avoid the use of two pipe

systems where the circulated fuel is returned to the

tank. If this cannot be avoided make sure that the

return pipe is normally below the surface of the fuel

level within the storage tank. See B) Fig. 13.

The plug in the return line (R) must be a metal

bung.

In case of use with gas oil containing up to 10%

bio blend, it will be essential to use exible oil lines

suitable for biofuel use.

Please contact EOGB for further information.

WARNING

WARNING

WARNING

6.1.1 Priming the pump6.1 Pump

1 pipe system

To prime the oil pump, loosen the port plug of the vacuum

gauge port V)(Fig. 12). Run the burner and wait until the

fuel ows out.

2 pipe system /

1 Pipe Suction Li With De-Aerator

To prime the oil pump, loosen the port plug of the pressure

gauge port P)(Fig. 12). Run the burner and wait until the

fuel ows out. Should a lock-out occur prior to the arrival of

the fuel, tighten the port plug to prevent air re-entering the

pump, and wait at least 30 seconds before repeating the

operation.

or

With the aid of an oil priming suction pump, attach and pull

the oil through the vacuum gauge port V)(Fig. 12)

In a 2 pipe operation before starting the burner,

make sure that the return pipeline is not clogged/

obstructed and the oil pump is congured cor-

rectly as if not, then the pump sha seal will break

due to overpressure (not covered by

manufacturer’s warranty).

The pump vacuum should not exceed a

maximum of 0.4 bar (30 cm Hg).

Beyond this limit, gas is released from the oil.

WARNING

WARNING

WARNING

In a 1 pipe system or a pressurised system, the

installer must ensure that the supply pressure is not

above 2 bar. Above that level, the pump seal is

subject to too much stress.

Loading...

Loading...