Electrical System

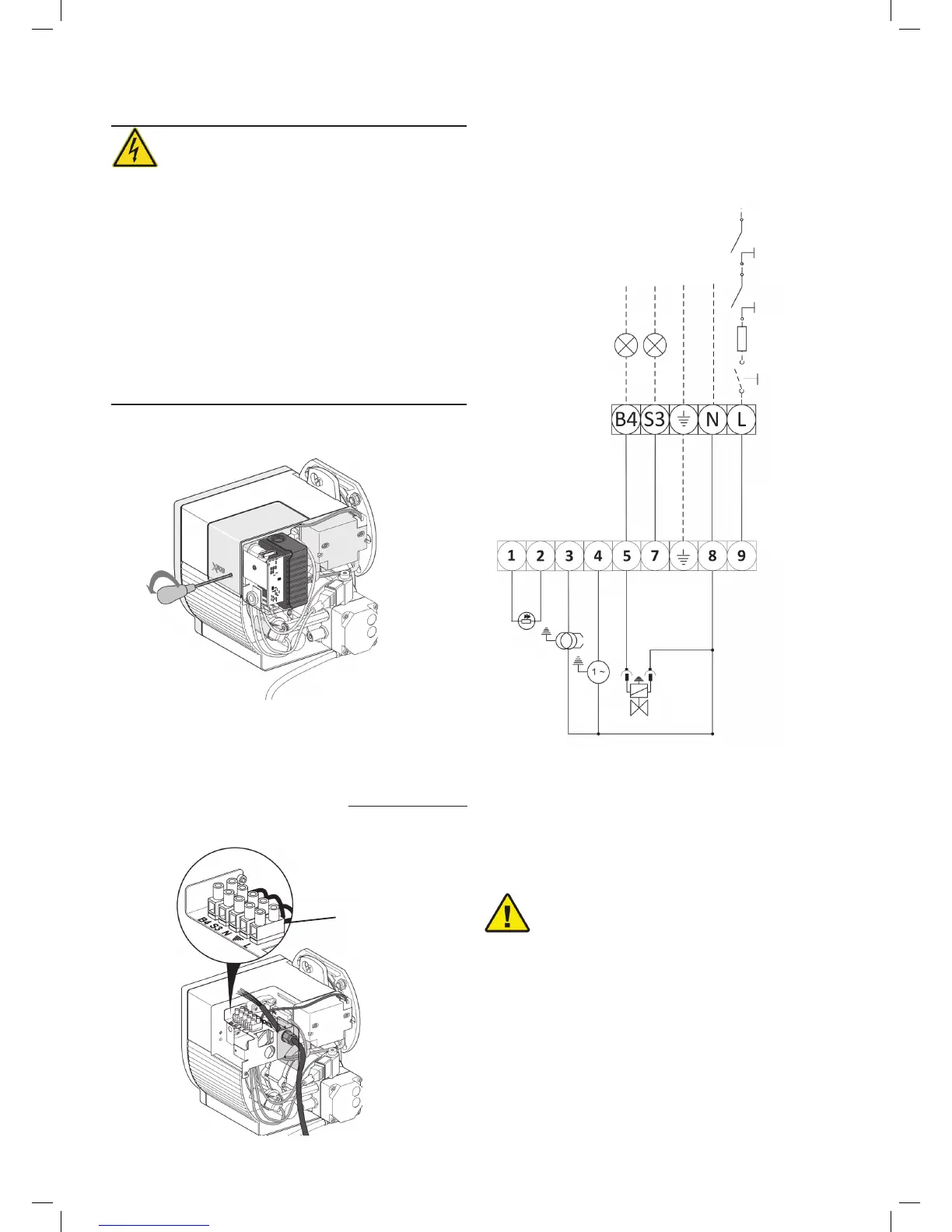

7.2.1 Electrical wiring

This operation must be performed by a qualied

engineer with the boiler turned o and mains

power disconnected.

Do not swap neutral and phase over, follow the di-

agram shown carefully and ensure their is a good

earth connection

The electrical wiring carried out by the installer

must be in compliance with the rules in force in

the country.

The section of the conductors must be at least

1mm2 (unless requested otherwise by local stand-

ards and legislation).

DANGER

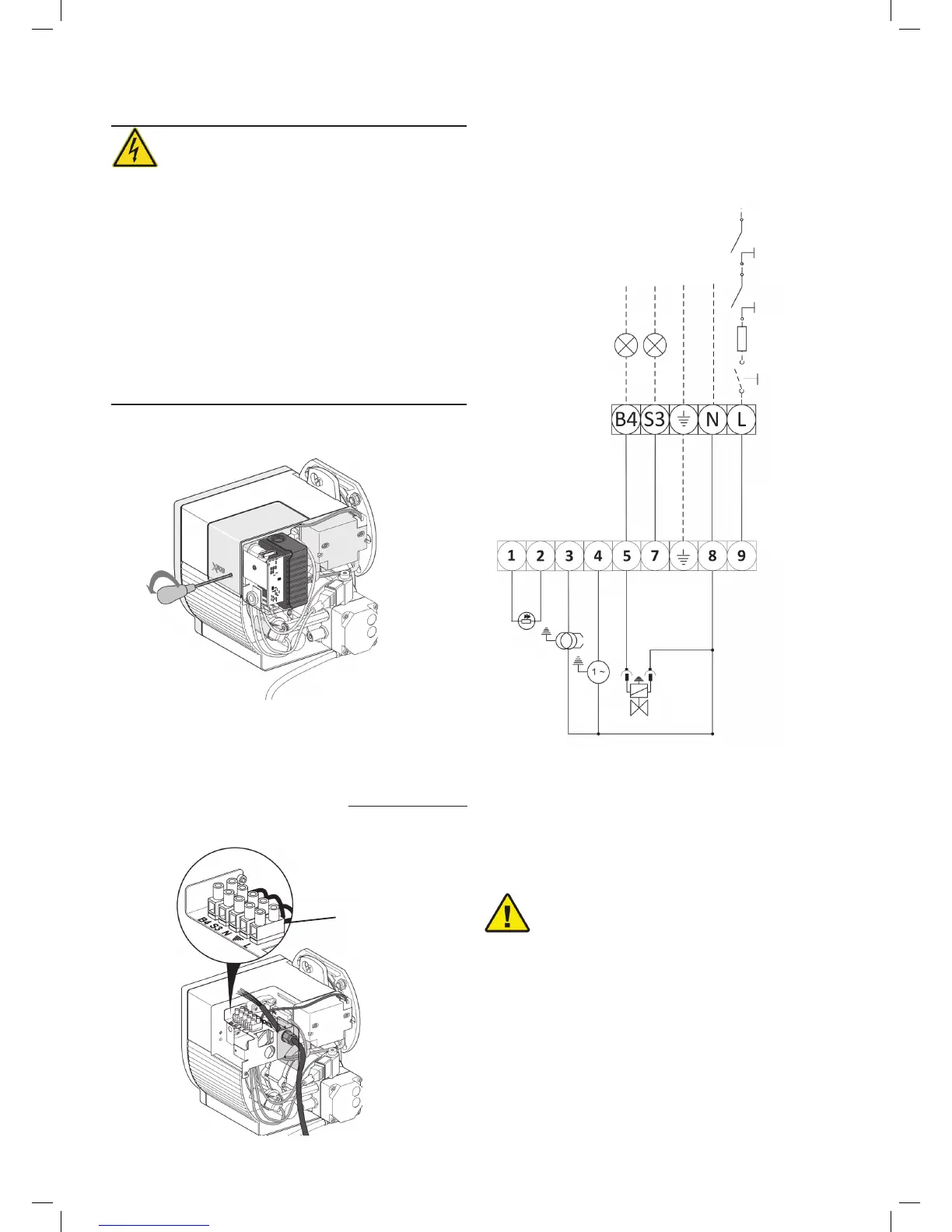

If tting the X400 or X500 then before carrying out any elec-

trical wiring, the electronics cover must be removed (see Fig

18 & 19)

Internal Components

A1 - Satronic S98 Wiring Base

PE - Photocell

T - Transformer

M - Motor

V1 - Solenoid Valve

X3 - 5 Pin Terminal Strip

A1

PE

T

M

H1H2

Neutral

Earth

Live

1 ph 230v - 50Hz

S1

F

TC

TS

V1

X3

X3

Once the cover has been removed then all wiring can be

wired into the 5 pin terminal strip (X3 on Fig 19) please see

wiring diagram for further information.

If the X-series burner is being tted to a WORCESTER BOILER

that has 6 wires then please follow instructions given in sec-

tion 7.2.3

Fig. 14

Fig. 15

External Components

S1 - Isolation Switch

F - Fuse (5 amp)

TC - Control thermostat

TS - Limit Thermostat

H1 - Lockout indicator

H2 - Burner Run Indicator

TESTING:

Check the shut-down of the burner by opening

the thermostats and the lock-out by darkening

the photo-resistance.

WARNING

Wiring Diagram for X400 & X500

(without 7pin connections)

7.2.2 X400 & X500 Electrical wiring (No 7 pin plug)

Fig. 16

Loading...

Loading...