Oil Supply

6.2 Oil Supply

(See Fig.17).

Plastic or steel tanks should be installed to BS5410.

A steel tank should also conform to BS799: part 5 and be

arranged with a slope of 1 in 24 away from the outlet valve

with a sludge cock at its lower end.

Do not use galvanised steel tanks or pipework for the oil

supply system.

Do not use soldered joints in the oil supply pipework as this

could cause a hazard in the case of a re.

All X-Series burners are supplied and congured to be con-

nected to a single pipe gravity feed system. Details of how

to convert the burners to a 2 pipe sub-gravity feed system

are shown in Fig. 15

6.3 Oil Supply System

(Fig. 13 a) 1 Pipe System

If a single pipe system is employed, then the tank must be

positioned such that the oil level does not exceed 4 metres

above the level of the burner oil pump and in addition the

oil level must be at least 0.3 metres above the level of the oil

pump. Should it prove impossible to site the tank below the

4 metres maximum oil level, a head breaking device must

be installed between the tank and the burner.

(Fig. 13 b) 2 Pipe System

If a 2 pipe system is used then the maximum suction height

allowable is 3.5 metres.

(Fig. 13 c) 1 Pipe Suction Li with De-aerator

If a single pipe suction li with a de-aerator is used, the oil

tank must be positioned below the burner. An inlet and

return loop should be created between the de-aerator

and oil pump. The oil pump should be connected as for a

2 pipe system. Details of how to convert to a 2 pipe system

are shown in Fig. 13.

Oil inlet and return exible hoses should be connected to

the oil pump inlet and return ports.

Table D is a general guide to determine the maximum

allowable pipe run when using a de-aerator.

Table D does not override the de-aerators manufacturer’s

instructions and should only be used in conjunction with

the manufacturer’s instructions.

If a non-return valve is not incorporated within the de-aer-

ator unit, a non-return valve should be tted in the oil line

between the oil tank and the de-aerator.

NOTE: If a de-aerator is used it should be tted externally to

the building (with exception to specic internally version in

which would have to be vented to the outside).

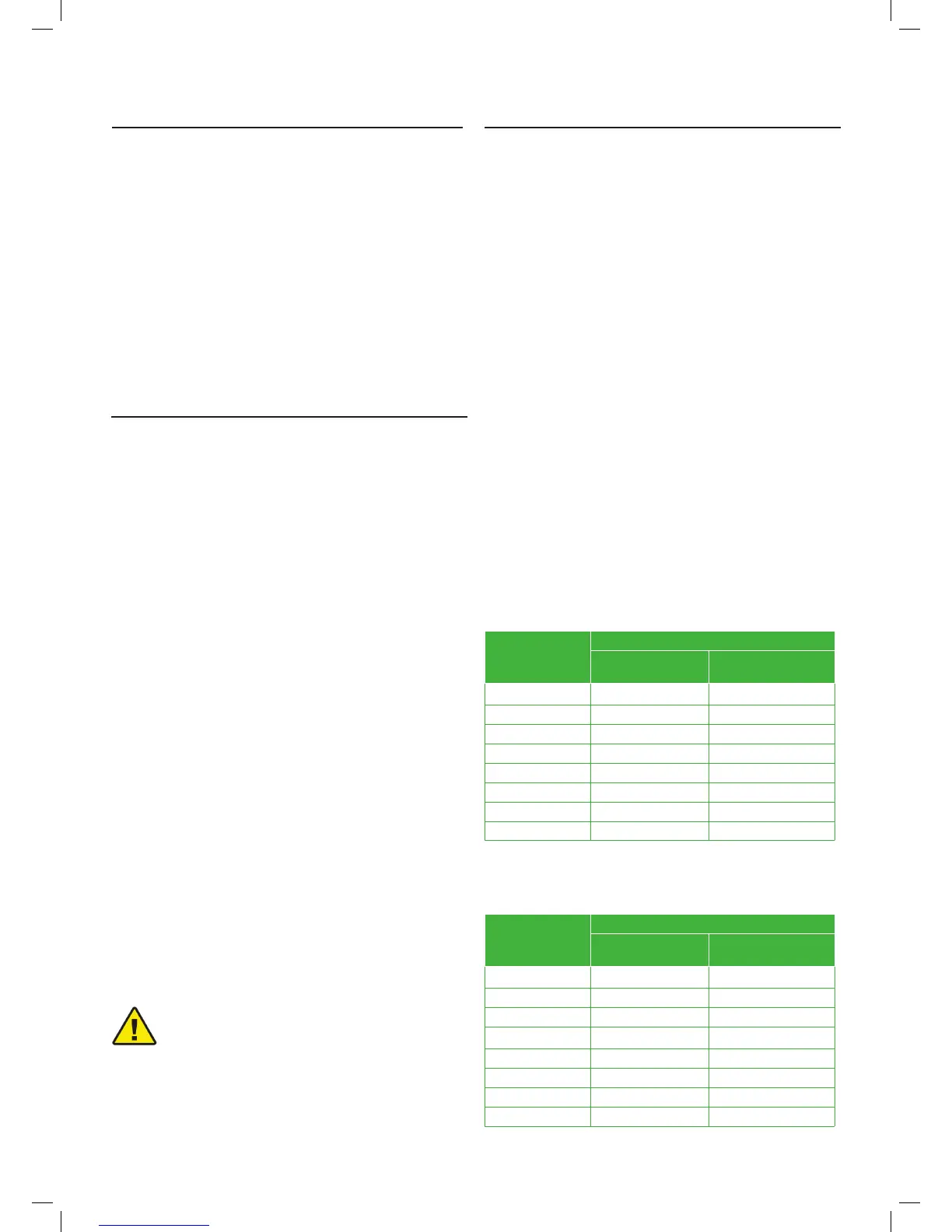

Table. B - 1 Pipe Gravity Feed System

6.4 Oil Supply Pipework

HEAD (metres)

Maximum Allowable Pipe Run (metres)

8mm inside dia pipe

(10mm OD copper)

10mm inside dia pipe

(12mm OD copper)

0.5 12 30

1.0 25 69

1.5 37 91

2.0 49 100

2.5 62 100

3.0 74 100

3.4 87 100

4.0 99 100

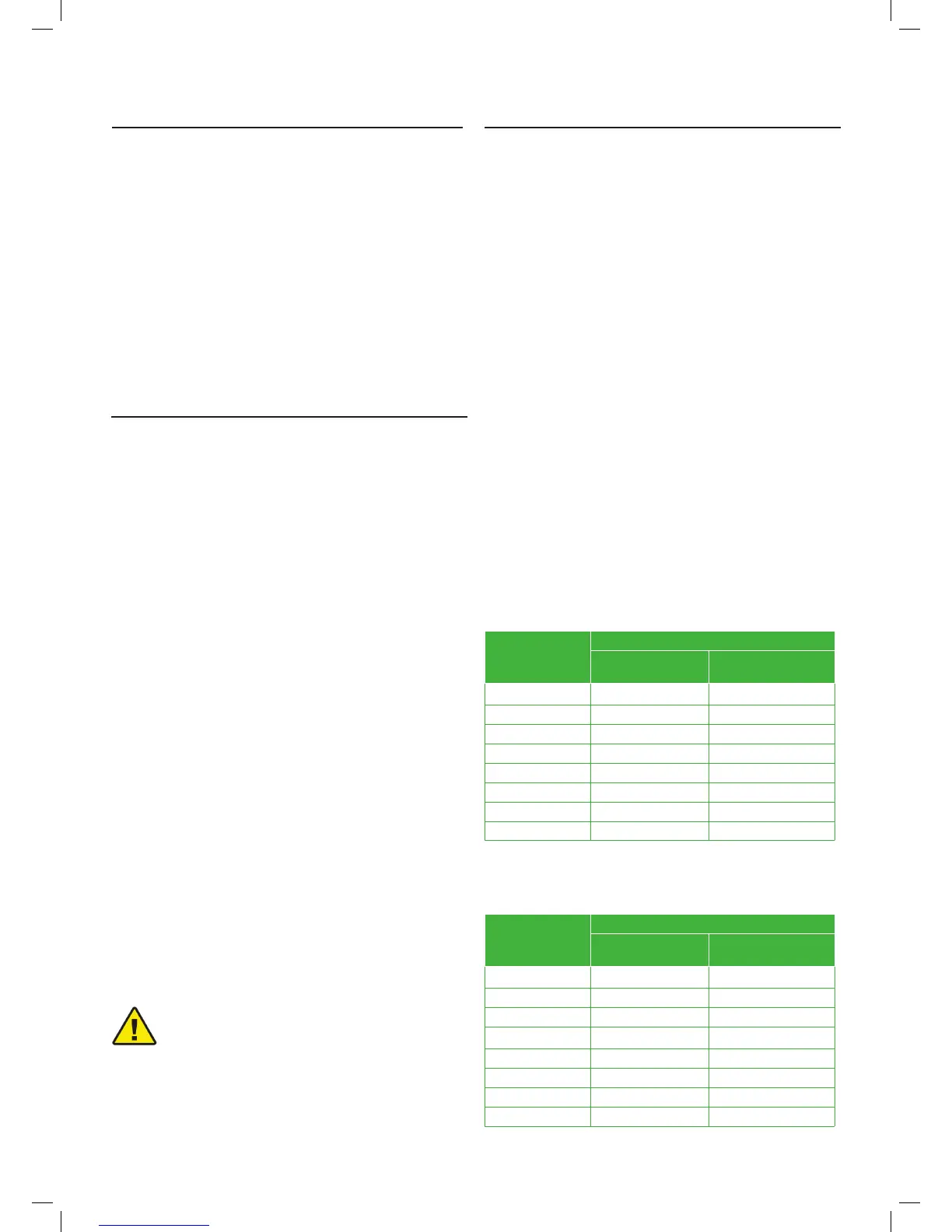

HEAD (metres)

Maximum Allowable Pipe Run (metres)

8mm inside dia pipe

(10mm OD copper)

10mm inside dia pipe

(12mm OD copper)

-.5 12 30

-.0 25 69

-.5 37 91

2.0 49 100

2.5 62 100

3.0 74 100

3.4 87 100

4.0 99 100

Table. C - 2 Pipe Sub-Gravity Feed System

a) The oil supply pipe diameter can be determined using

Tables B, C and D depending on whether a 1 or 2 pipe sys-

tem or 1 pipe suction li system is being installed. Selection

of the correct pipe diameter will depend on the position of

the oil storage tank relative to the burner and the length of

pipe run.

b) The oil supply pipe should be laid as level as possible to

avoid air pockets and unnecessary friction losses.

c) The following components should be tted in the fuel line

between the storage tank and burner:

1. A manual isolating valve installed as close to the

tank as possible.

2. A re valve in accordance with BS5410, Part 1 as

shown in Fig 17. The re valve should be tted externally with

a re detection element located within the appliance case.

Use of a capillary type valve will allow a neat and simple

installation. A suitable valve is the KBB manufactured by

Teddington Controls Limited.

3. An oil lter should be tted close to the oil storage tank. If

there is doubt about the internal oil line condition, a further

lter should be tted near the boiler.

You are advised to use additional lters on the fuel

supply line. It is recommended that a good quality

fuel lter at the tank (Fig. 13) and a secondary

lter (60 µ for gas oil and 15 µ for kerosene) are

used to protect the burner pump and nozzle from

contamination.

In case of biodiesel use, pay attention to install

compatible lters. (Contact EOGB for more infor-

mation)

CAUTION

Loading...

Loading...