Burner Operation and Commissioning

8 Burner Operation and Commissioning

8.1 Notes on safety for the rst start-up.

The rst start-up of the burner must be carried

out by qualied personnel, as indicated in this

manual and in compliance with the standards/

regulations and local authority legislation

Check the correct working of the adjustment,

command and safety devices.

WARNING

WARNING

In conformity with Eciency Directive 92/42/EEC the

application of the burner on the boiler, adjustment and

testing must be carried out observing the instruction

manual of the boiler, including verication of the CO and

CO2 concentration in the ue gases, their temperatures and

the average temperature of the water in the boiler.

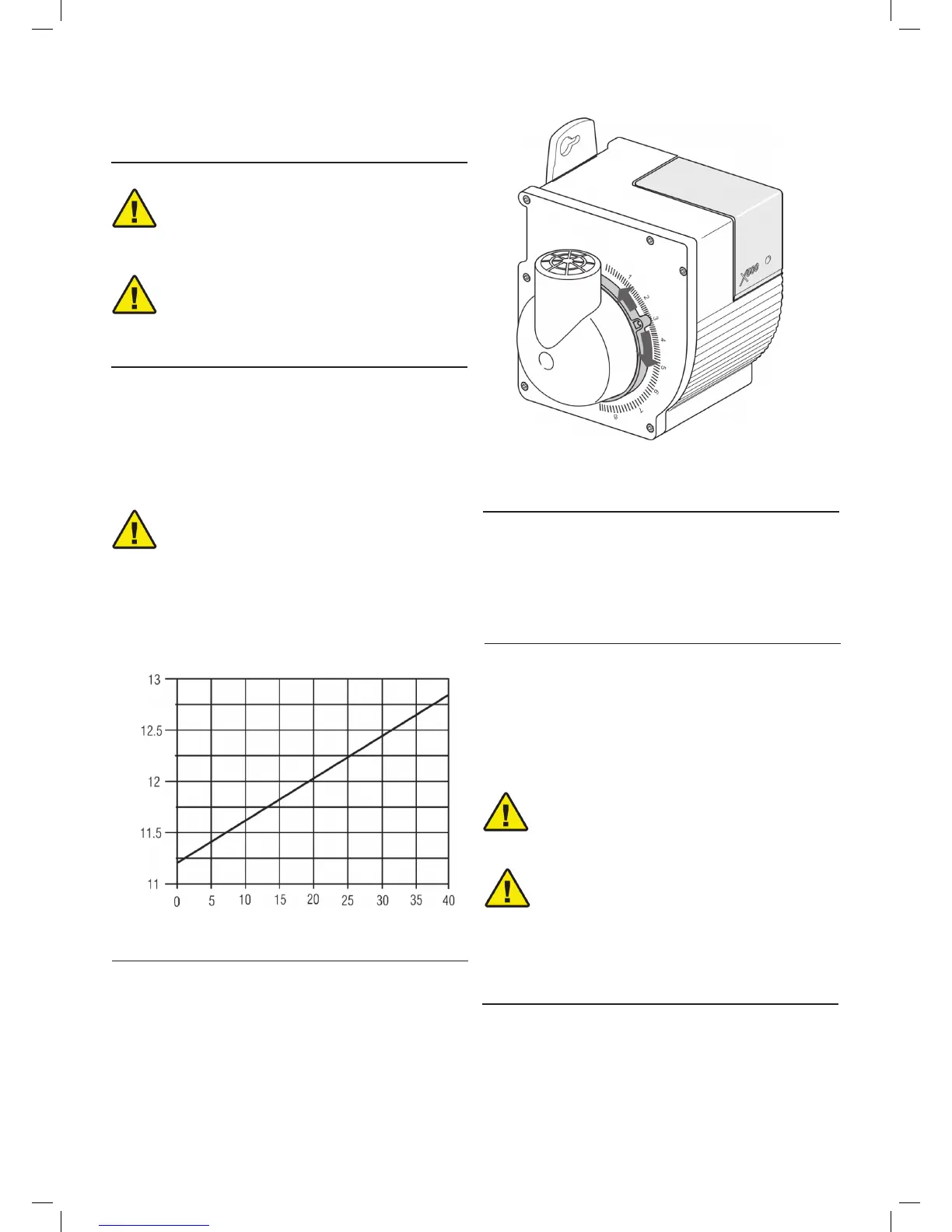

8.2 Combustion adjustment

Combustion air is drawn in from outside, mean-

ing there may be notable changes in tempera-

ture, which can aect the percentage of CO2.

You are advised to adjust CO2 in accordance

with the graph featured.

Example: outside air temperature 10 °C, adjust

CO2 to 11.6% (± 0.2%).

A CO level should be kept to a minimum and

ideally less than 100ppm but if in doubt then

contact EOGB.

WARNING

% CO²

Outside Air Temperature (°C)

Fig. 19

8.5 Nozzles installation

The burner complies with the emission requirements of the

EN 267 standard.

In order to guarantee that emissions do not vary, recom-

mended and/or alternative nozzles specied by the man-

ufacturers in the instruction and warning booklet should be

used. The information given in Table E should only be used

as a guide where no information is provided by the boiler/

application manufacturer’s instructions/booklet.

It is advisable to replace nozzles every year during

regular maintenance operations.

The use of nozzles other than those specied by

the manufacturer may result in emissions that do

not conform to the values set by the regulations in

force, and in extremely serious cases, may cause

potential hazards to people and objects.

The manufacturing company shall not be liable for

any such damage arising from non-observance

of the requirements contained in this manual.

8.5.1 Nozzles recommended

• Delavan type A - W;

• Steinen type Q - S;

• Danfoss type H - S - EH - ES.

Angle 60° & 80° are advisable

WARNING

CAUTION

8.4 Pump pressure

The pump pressure when it leaves the factory (unless other

wise specied) will be set to run on kerosene at 145psi (10

bar). Pump pressure should then be set to appliance

manufacturer’s recommendations depending on what

nozzle size is recommended (see Table 5 for more info).

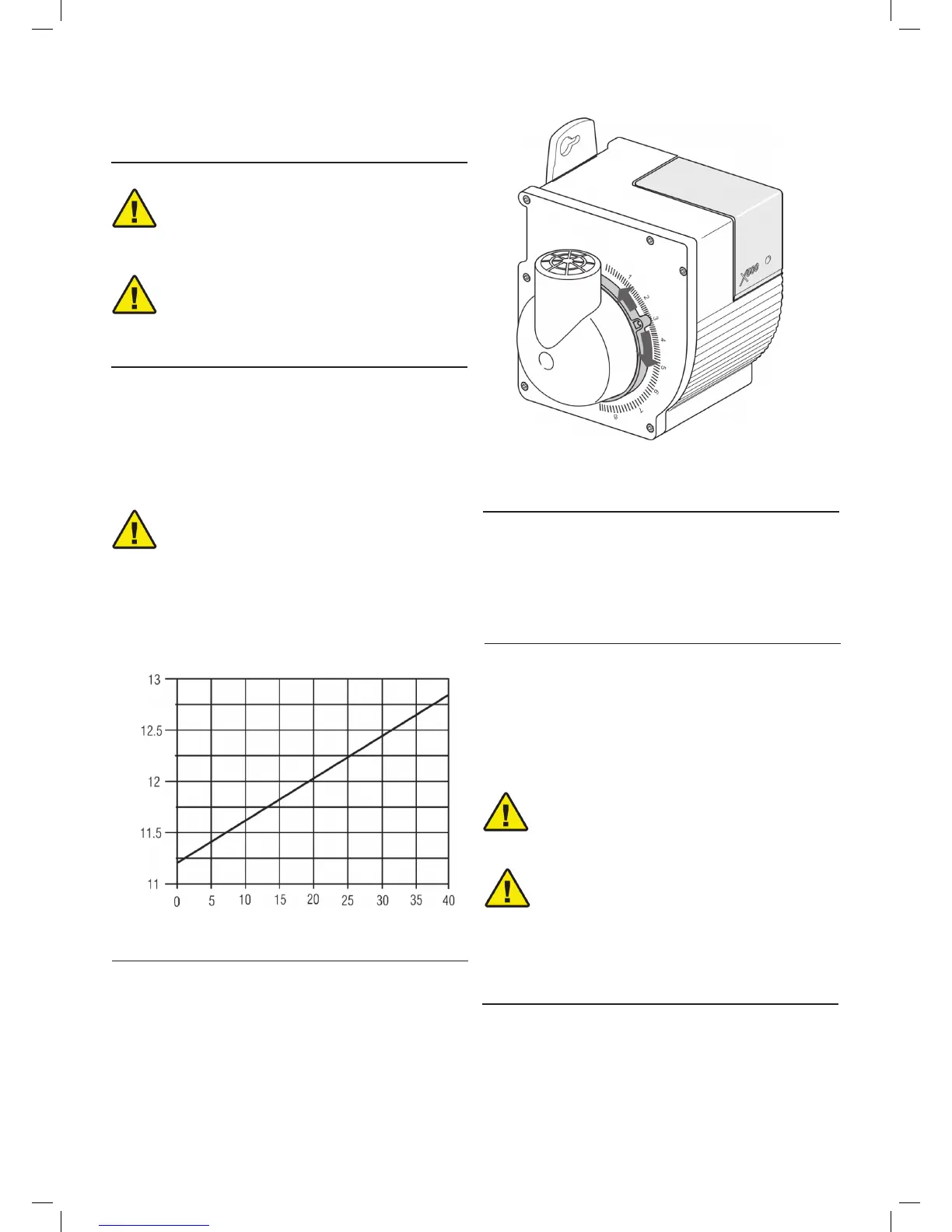

8.3 Burner combustion adjustment

From a suitable test point on the boiler, or in the ue, a smoke

reading should be taken to ensure clean smoke-free com-

bustion.

With the aid of a ue gas analyser, and by making adjust-

ments to the air adjuster, the combustion can be set for max-

imum eciency (see Fig 19).

The air damper control rotates to adjust the amount of com-

bustible air (see Fig 20) and is locked in place by tightening

the air damper locking screw. (see page 22, A Fig 25 )

Air control

Clockwise = MORE air

Anti-Clockwise = LESS air

Fig. 20

8.5.1 Nozzles recommended

Loading...

Loading...