Burner Oil Type Nozzle Size Spray Pattern

Boiler

Eciency Rating *

Pump pressure (psi) Output (kW) Air Damper

X400

Kerosene

0.40

ES / EH 90%

100-150 12-14.7

Low

0.45 100-150 13.6-16.6

0.50 100-150 15.1-18.5

**0.55 100-150 16.6-20.3

0.60 100-150 18.1-22

0.65 100-150 19.6-24

0.75 100-150 22.6-27.7 Low/High

0.85 100-150 25.6-31.4

High

1.00 100-150 30.1-36

Gas Oil

0.30

S / H 90%

180-250 13.7-16.1

Low

0.35 180-250 16-18.9

0.40 180-250 17.4-20.4

0.45 180-250 19.8-23.2

0.50 180-250 22.3-26 Low/High

0.55 180-250 25.1-29.5

High0.60 180-250 28.2-33.1

0.65 180-230 31.8-36

X500

Kerosene

1.00

EH / ES

90%

125-150 34-36.9 Low

1.10 100-150 33.2-40.6 Low/High

1.20

S / H

100-150 40-49

High

**1.25 100-150 42.4-51.8

1.35 100-150 46.5-56.9

1.50 100-145 52.5-62

Gas Oil

0.65

S / H 90%

210-250 34-38

High

0.75 180-250 35.41.1

0.85 180-250 39.3-46.4

1.00 180-250 44.2-52.1

1.10 180-250 50.4-59.4

1.20 180-250 52.9-62

X600

Kerosene

1.35

S / H 90%

120-150 50.56.9

High

*1.50 100-150 52.5-62

1.65 100-150 54.7-66.9

1.75 100-150 58.9-72.1

2.00 100-145 66.7-80.3

Gas Oil

1.00

S / H 90%

230-250 50-52.1

High

1.10 180-250 50.4-59.4

1.20 180-250 52.9-62

1.25 180-250 56-66

1.35 180-250 61.5-72.40

**1.50 180-250 69.4-73.15

1.65 180-225 72.3-80.7

** Standard test nozzle supplied with the burner.

Burner Operation and Commissioning

Table E

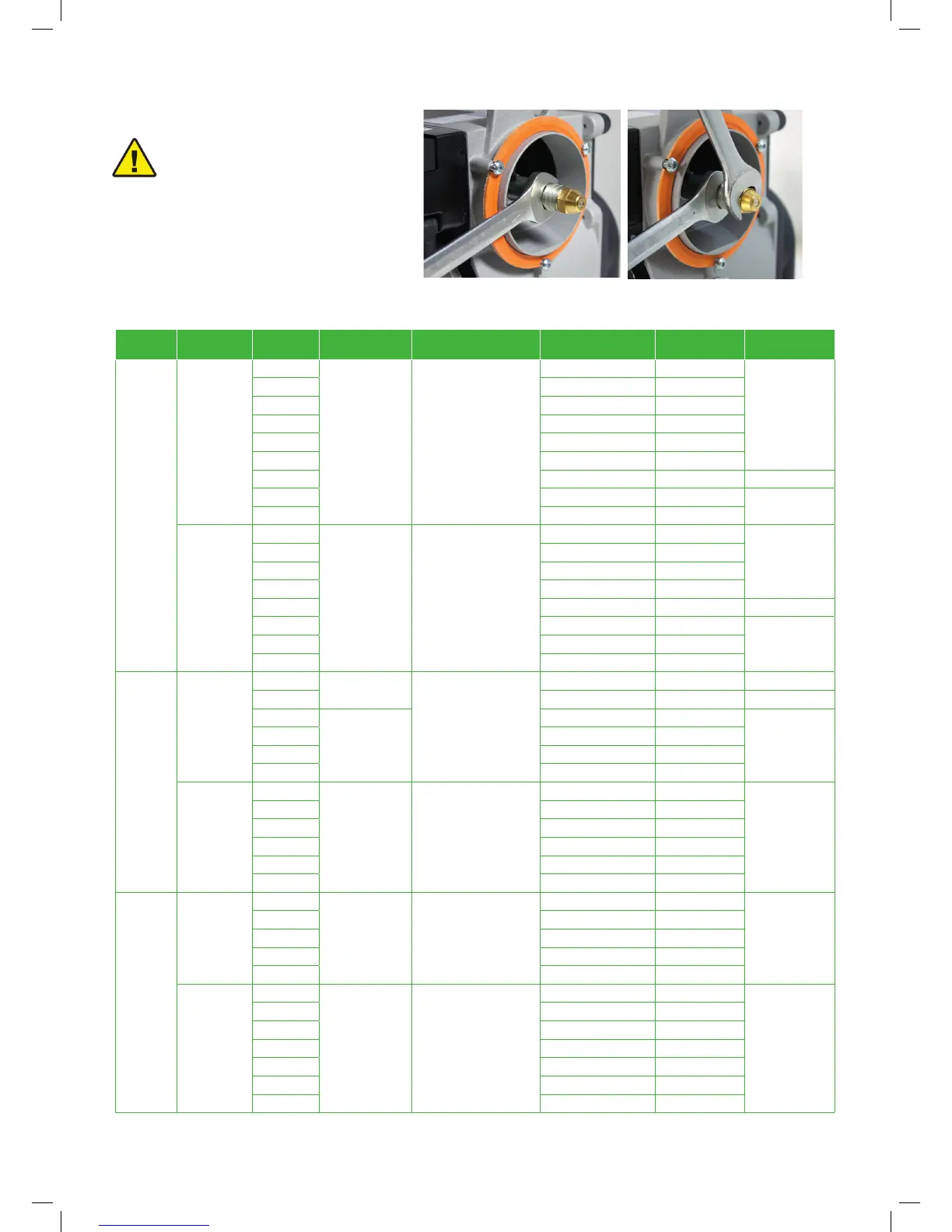

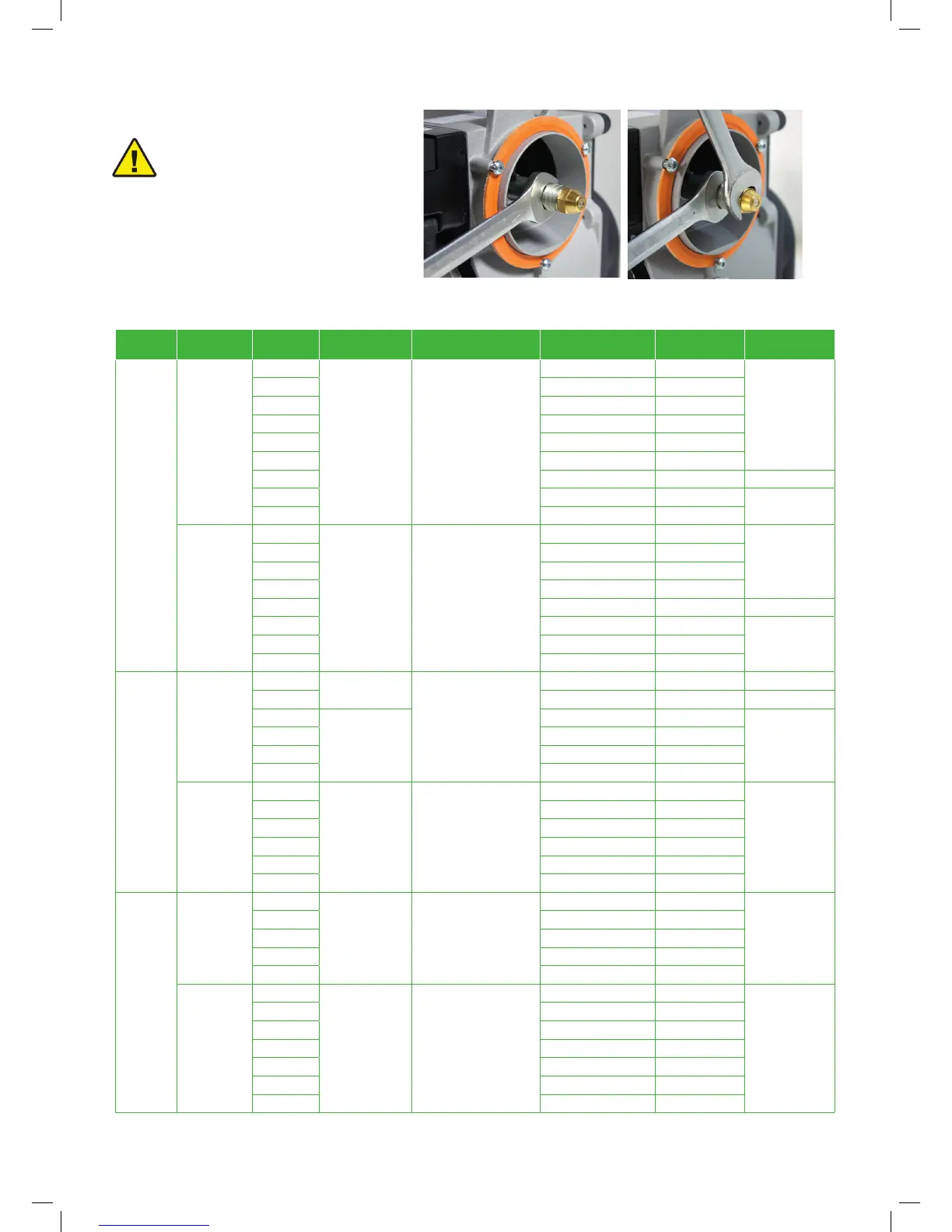

It is important that the nozzle holder is

prevented from rotating by use of a

second spanner while unscrewing the

nozzle (see Fig 21 & 22)

*Please note that boiler eciency may dier

so this table should be used as a guide only.

If in doubt then contact the appliance/boiler

manufacturer for advice

CAUTION

Fig. 21

Fig. 22

Loading...

Loading...