SmartROC T35/T40 21 Winch

136 No: 7026962571.1.7027002891 en-US

n

Check that the tightening torque on (D).

n

Check that the tightening torque for hydraulic motor (E).

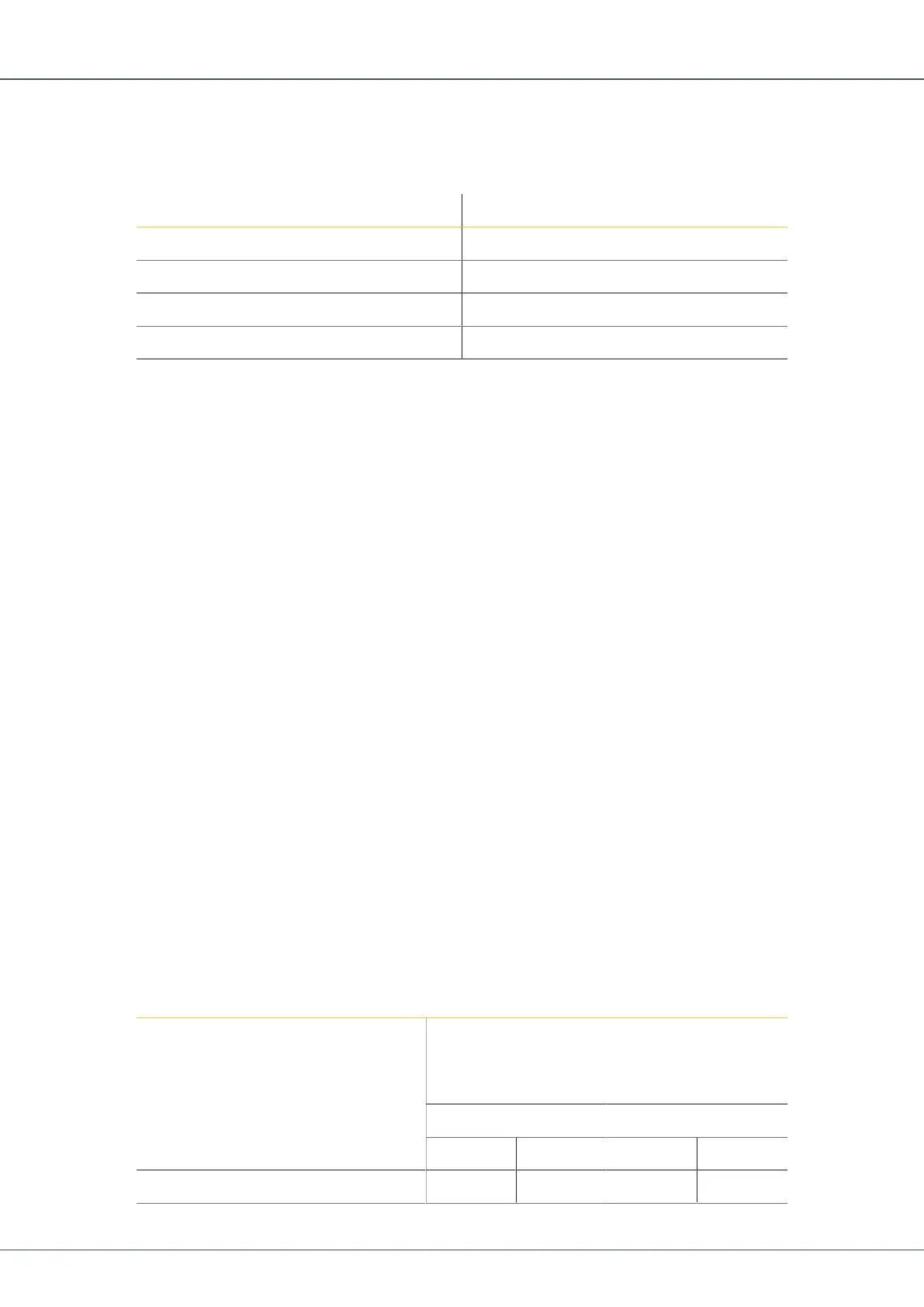

Component Tightening torque

Winch frame 350 Nm (258 lbf.ft)

Slide bolts 140 Nm (103.25 lbf.ft)

Attachment bolts 350 Nm (258 lbf.ft)

Hydraulic motor 29 Nm (21.38 lbf.ft)

21.7 General Checking Guidelines for Wire Ropes

Wire ropes must be scrapped when they display any of the following:

• Wire rope break at attachment

• Certain number and type of wire rope breaks

• Concentrations of wire rope breaks

• Occurrence of wire rope breaks due to operating time

• Occurrence of strand breaks

• Surface wear

• Effects of heat

• Reduced elasticity

• Decreased wire rope diameter

• Permanent extension of the wire rope

• Deformation of the wire rope

21.7.1 Checking Wire Rope for Wire Breaks

Wire breaks occur after a certain operating time depending on operating conditions and

then occur more frequently. The number of wire breaks in relation to the operating time

must be determined and documented. It can then be used to estimate the future increase

in wire breaks and the foreseeable time point for scrapping. On 6 and 8-strand wire ropes,

wire breaks are primarily superficial.

• Broken wires at wire rope ends indicate that they have been heavily loaded and can

cause faulty end mountings. Shorten the wire rope and reattach it. Check that the

length of the remaining wire rope sufficient.

• If there are concentrations of wire rope breaks, the wire rope must be scrapped. If

such concentrations occur within a length less than 60 cm (23.6 in.) or on an individual

strand, the wire rope must be scrapped. Even if the number of wire breaks is less than

the maximum specified in the table.

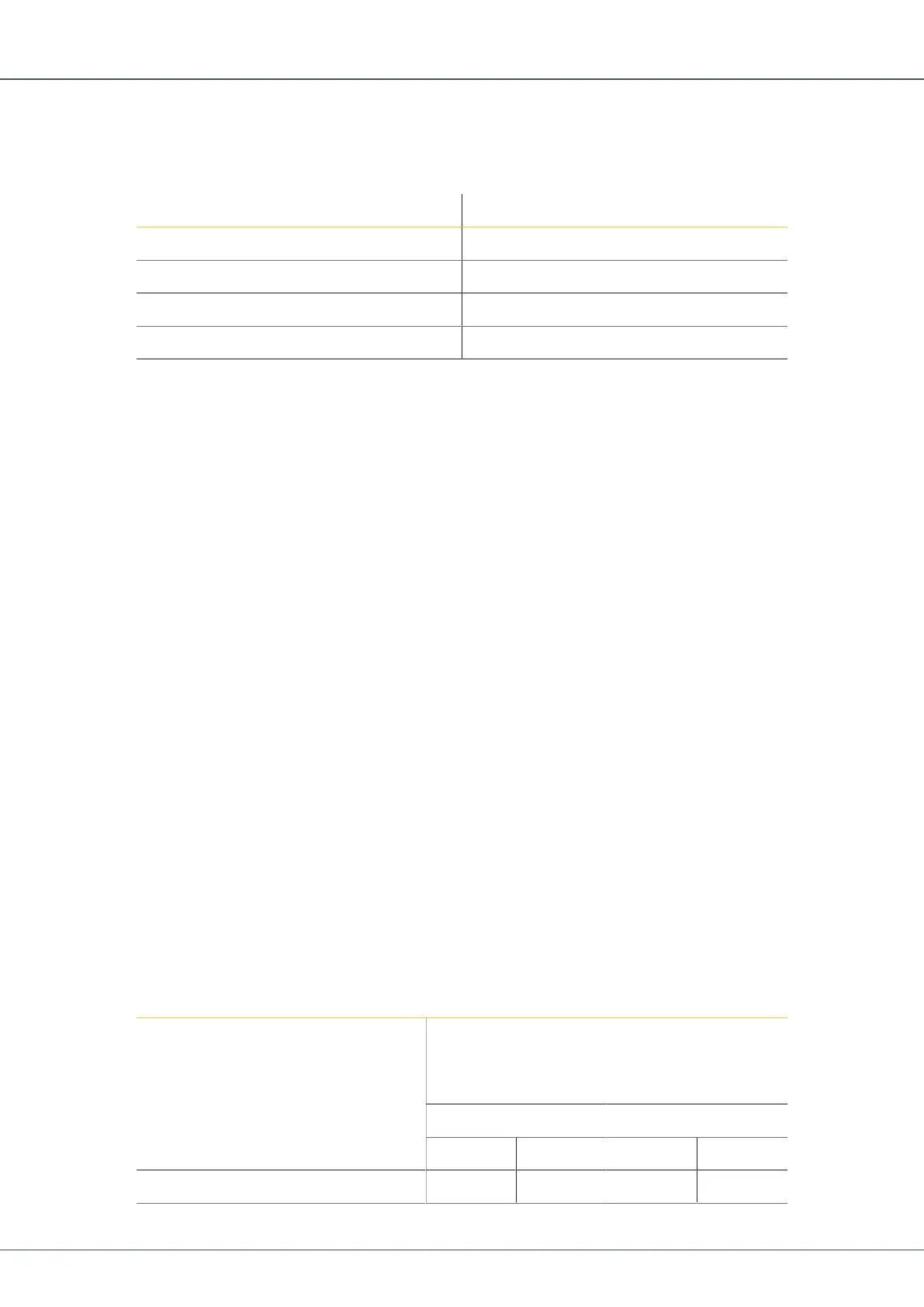

Number of load-bearing wires in outer

strand.

Filler wire is not considered load-bearing.

Number of visible wire breaks that require scrapping

Machine groups M1 and M2

Over a length of wire rope diameter (d)

Cross Lay Equal Lay

6d 30d 6d 30d

201–220 9 18 4 9

Loading...

Loading...