Maintenance 5. Arm #1

96 LS Rev.10

CAUTION

■

adjust (loosen or tighten) the mounting bolts between the flexspline and

cross roller bearing unit.

If the mounting bolts are adjusted, the flexspline and

cross roller bearing unit must be

aligned by the maker of the reduction gear unit.

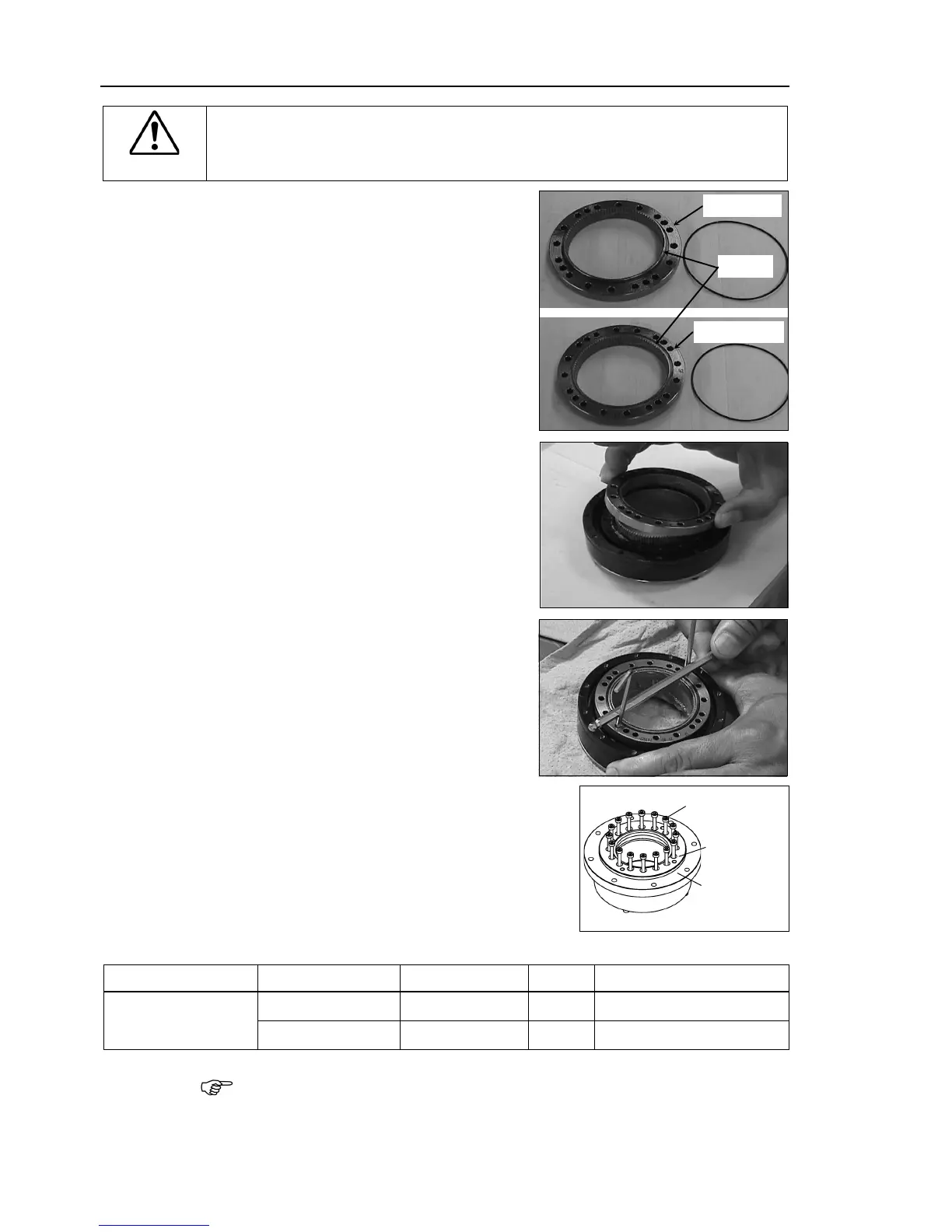

O-rings into the grooves on both

s of the new circular spline.

sure that the rings do not come out

Face the convex side of the circular spline

down,

and then fit it into the flexspline.

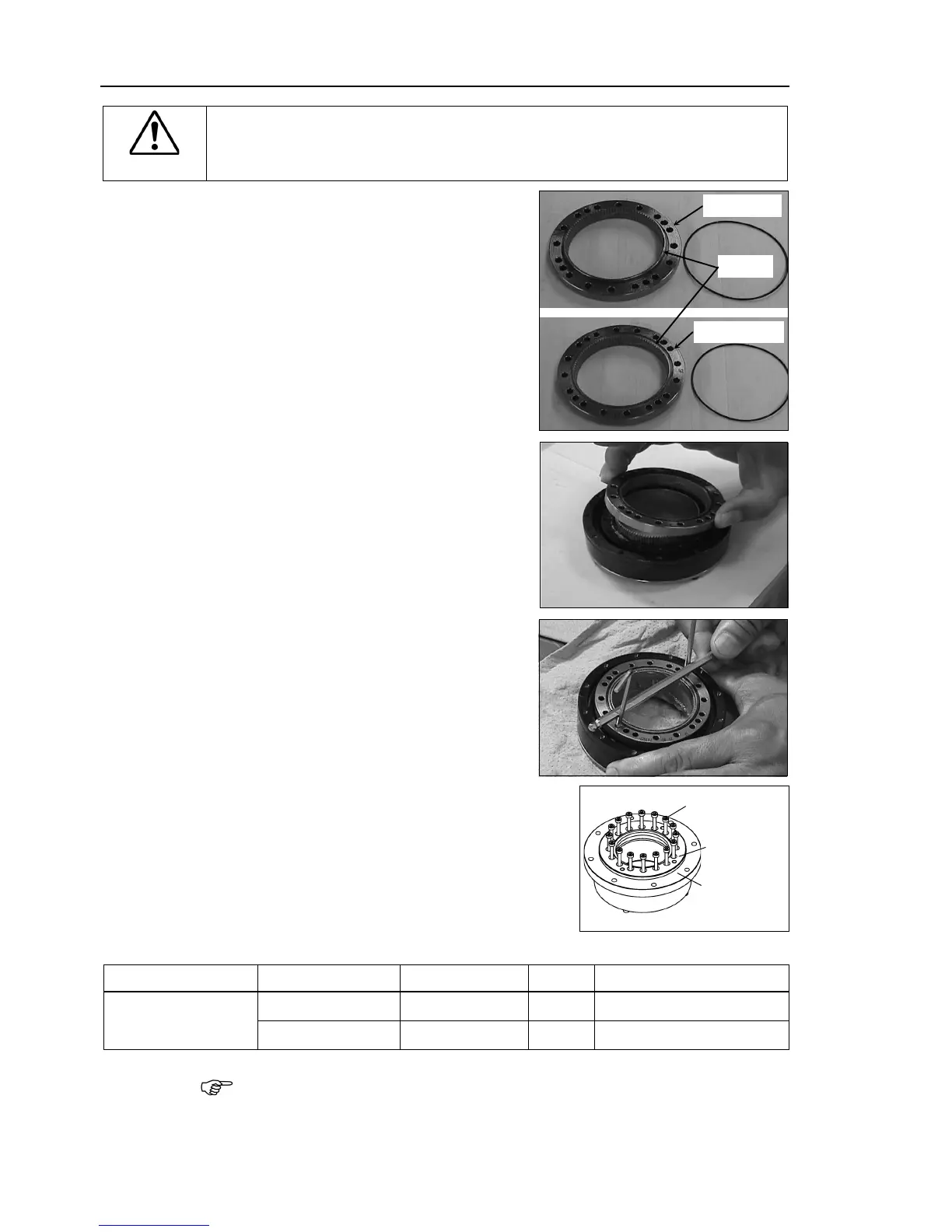

atch the screw holes on the inner ring of

the cross roller bearing unit and the

through holes of the circular spline.

the reduction gear flange to the circular

asten all bolts in a crisscross pattern so

the bolts will be fastened evenly. Then,

tighten each bolt securely

at the torque specified in

LS3: 16-M3×20

LS6: 16-M4×25

Item Manipulator type Bolt type Bolts Tightening torque

Joint #1 reduction

gear unit

LS3

M3×20 16

2.35 N⋅m (24 kgf⋅cm)

LS6

M4×25 16 5.4 N⋅m (55 kgf⋅cm)

careful not to apply too much force since it may damage the parts.

Loading...

Loading...