Maintenance 7. Arm #3

114 LS Rev.10

a new Z belt through the shaft.

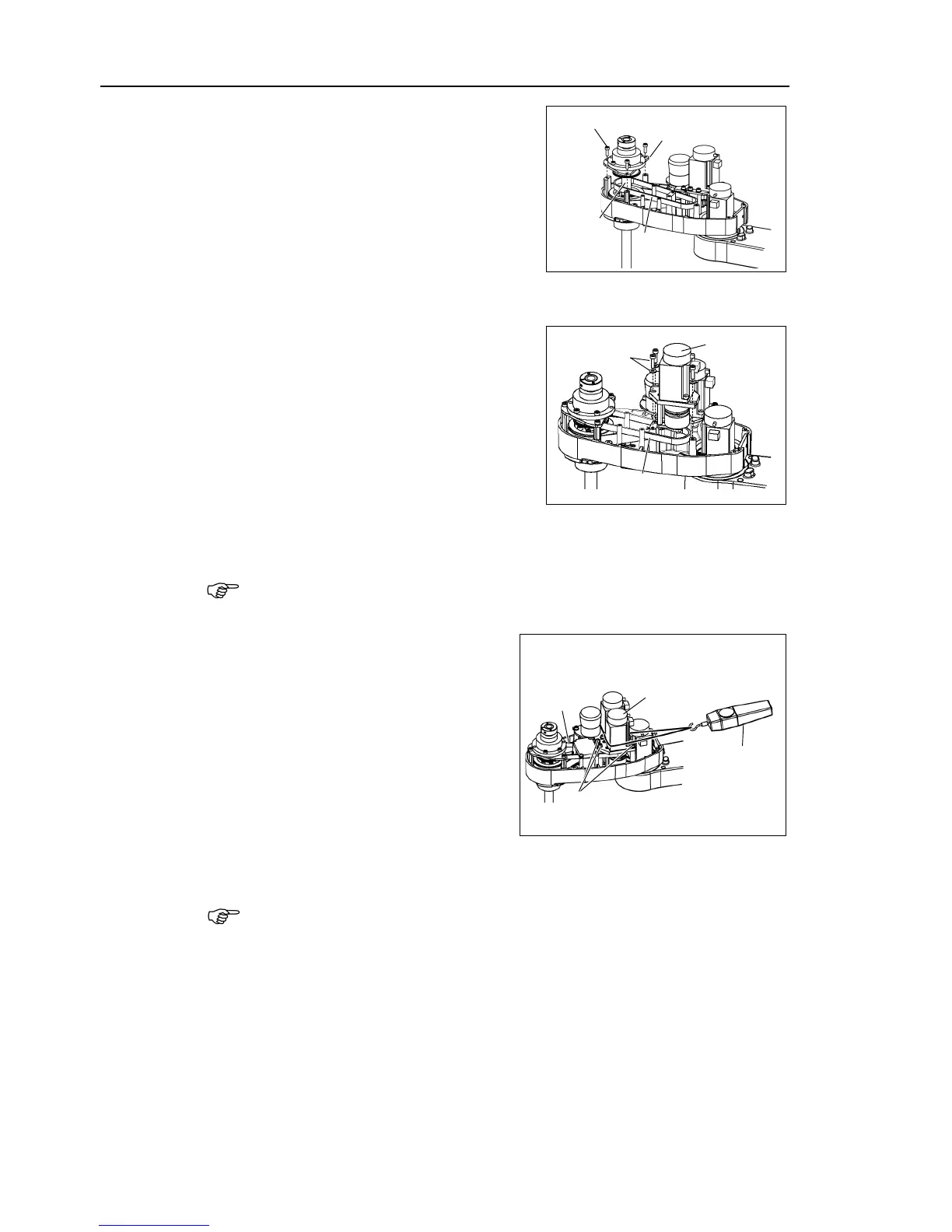

around the spline plate pulley.

Secure the spline plate with 3 screws.

Loosely secure the spline plate on the Arm

#2 and move the shaft up and down several

times before firmly secure the spline plate.

the Joint #3 motor unit back in the arm.

Pass the brake cable and special power

supply through the Z belt.

Place the Z belt around the Z1 pulley and Z2

pulley, with the gear grooves of the belt

fitting into grooves of the pulleys

completely.

Loosely secure the Joint #3 motor unit to the

Arm #2.

Secure the ground wire with a mounting screw.

At this point, make sure that the Joint #3 motor

unit can be moved by hand, and it

not tilt when pulled. If the unit is secured too loose or too tight, the belt will

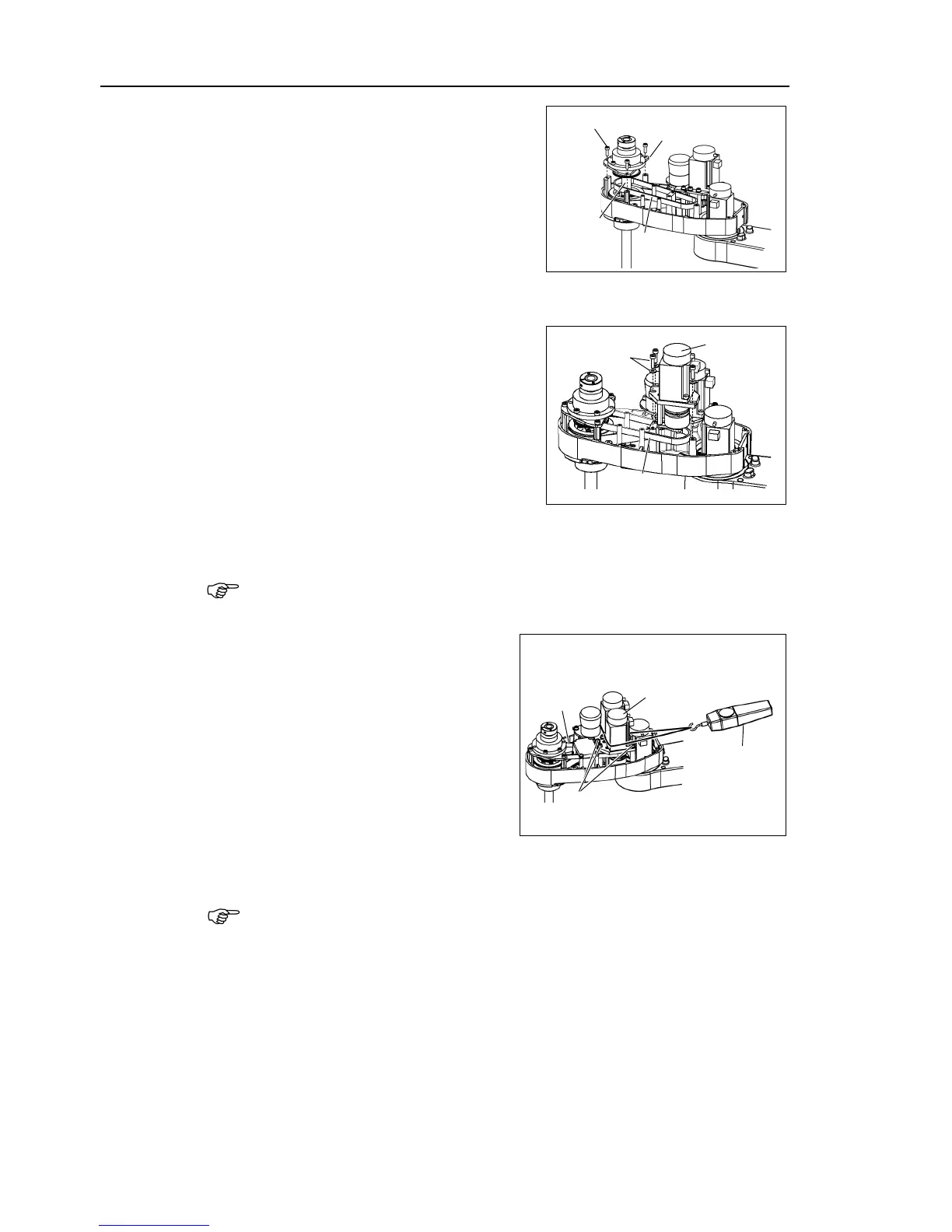

Apply the proper tension to the Z belt,

and then secure the Joint #3 motor unit.

a suitable cord or string around the

. Then, pull the cord using a force

or similar tool to apply the

specified tension shown in the figure on

the right

.

Z belt tension

69 N (7.0 ± 0.5 kgf)

check belt tension with the tension meter, refer to Maintenance:

7.4 Checking the

Timing Belt Tension (Z Belt).

Maintenance: 11.3 Replacing the Control Board.

X231, X241, X31, X35, X41.

Maintenance: 3.5 User Plate.

the cables with a wire tie in their original positions as before removed in

step (7). Do not allow unnecessary strain on the cables.

Loading...

Loading...