Maintenance 8. Arm #4

124 LS Rev.10

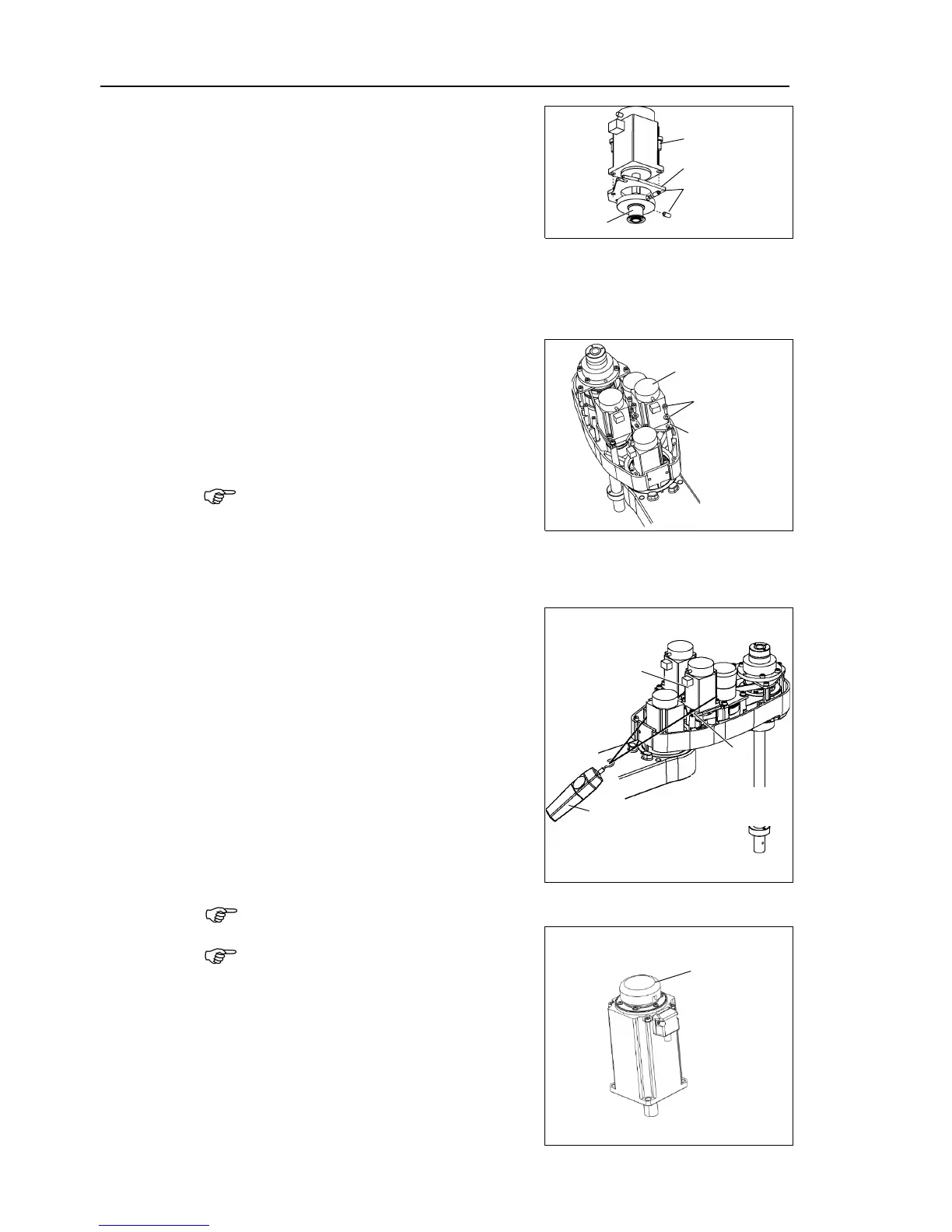

Mount the motor plate to the Joint #4 motor.

otor cables must be in the

2-M4×8

Set Screw

+ Bushing

the pulley to the Joint #4 motor.

Be sure to fit the end face of the pulley to

end face of the motor shaft.

screws vertically on the flat face of the motor shaft.

bushing into the other set screw hole to prevent damage to the motor shaft.

Place the pulley around the U1 belt and

p

lace the Joint #4 motor unit in the upper

Loosely secure the Joint #4 motor unit to

Arm

the motor unit can be moved by

, and it will not tilt when pulled. If the

secured too loose or too tight, the belt

grooves of the belt are fit

into those of the pulleys completely.

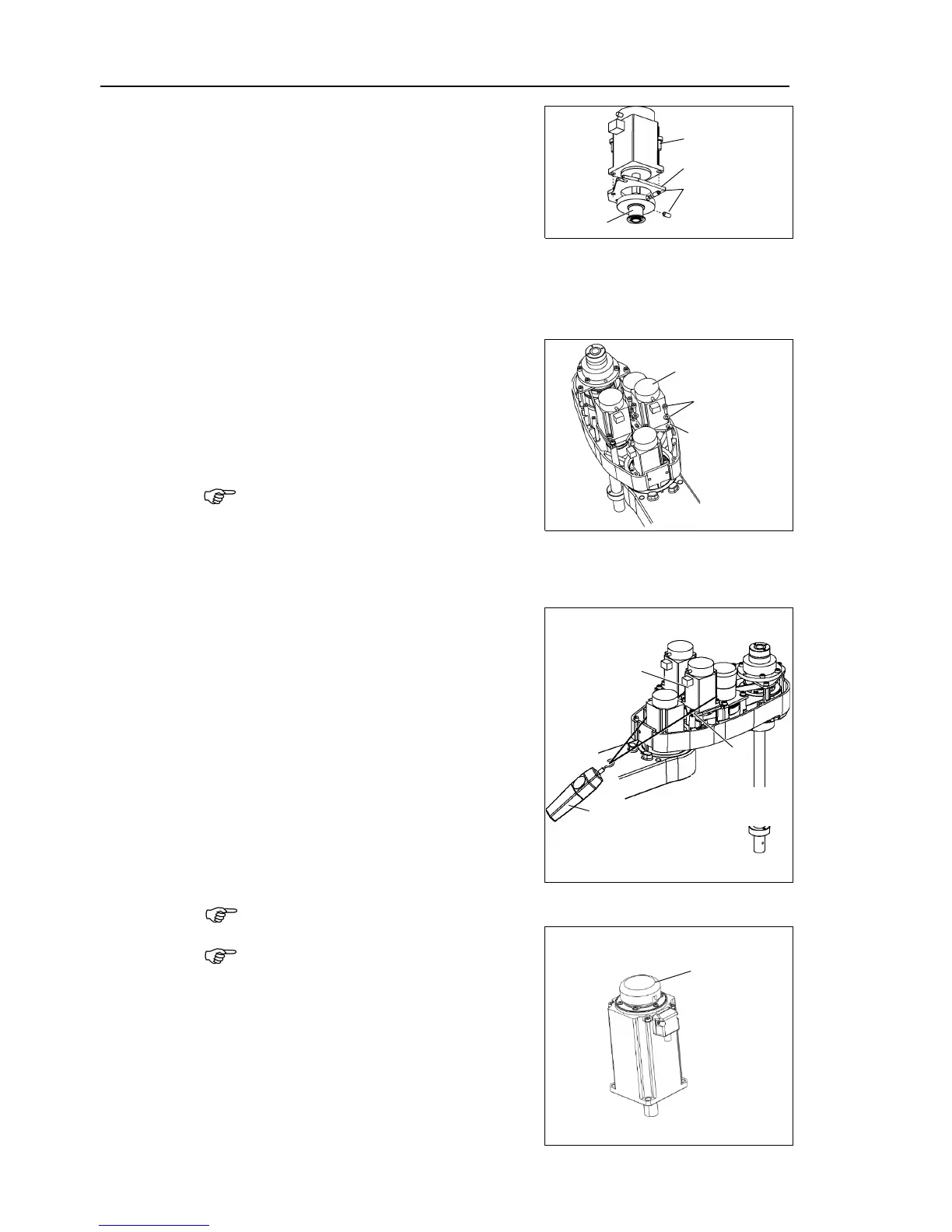

Apply the proper tension to the U1 belt and

secure

a suitable cord or string around the

Joint #4 motor unit near its mounting plate

ull the cord using a force gauge or

similar tool to apply the specified tension

shown in the figure

.

U1 belt tension

LS3 = 39 N (4.0 ± 0.5 kgf)

LS6(a) = 39 N (4.0 ± 0.5 kgf)

LS6(b) = 58 N (5.9 ± 0.5 kgf)

check belt tension with the tension meter, refer to Maintenance: 8

.4 Checking the

Timing Belt Tension (U1, U2 Belt).

When replacing the motor of the Joint #4,

remove the cap from the old motor and

install it to the new one.

If the Manipulator is operated while the cap

is not installed, the motor may be

due to entering of the foreign materials into

the rotating part of

interference of the rotating part and the

cables.

Loading...

Loading...