Maintenance 4. Alarm

126 VT Rev.1

The recommended replacement time for the parts (e.g. timing belts, motors, reduction gear

units) is when it reaches the L10 life (time until 10% failure probability). In the dialog

window, the L10 life is displayed as 100%.

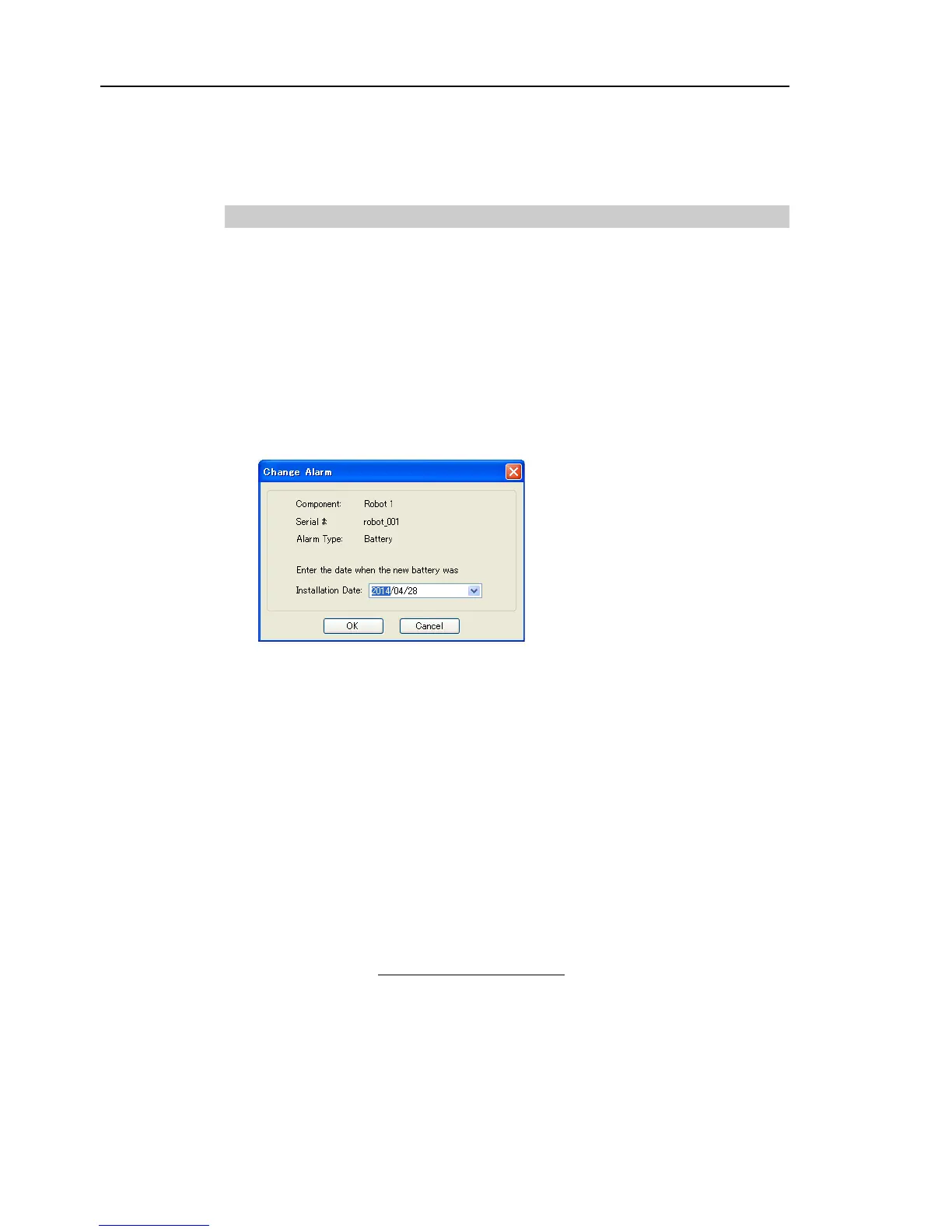

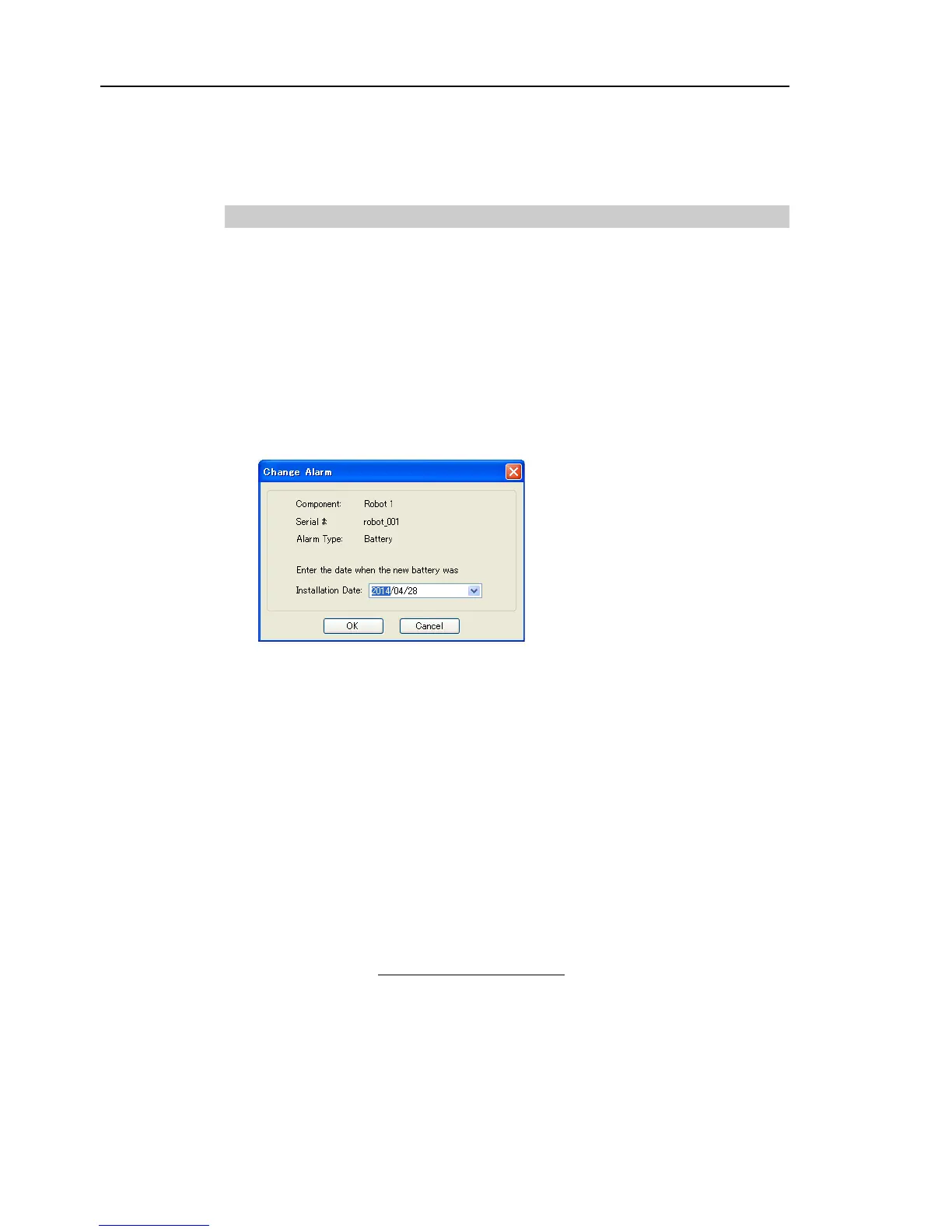

4.2.2 How to Edit the Maintenance Information

The configured Maintenance information can be edited in the EPSON RC+.

(1) Select the EPSON RC+ 7.0 menu-[Tools]-[Maintenance] to display the [Controller

Tools] dialog box.

(2) To edit the Maintenance information, display the [Maintenance] dialog box.

(3) Select “General” or specify the axis from the tree to display information of the target

parts.

(4) Select the alarm to be changed and click the <Change> button.

(5) Display the [Change Alarm] dialog box and enter any of the following.

Purchase or replacement date of the battery

Date of grease up

Purchase or replacement date of the timing belt

Purchase or replacement date of the motor

Purchase or replacement date of the reduction gear unit

(6) Click the <OK> button and change the specified alarm information.

The offset can be set for the consumption rate of already installed parts.

Follow the steps below to calculate a rough offset setting value.

1. Measure the usable months for the past operation by HealthRBAnalysis.

2. Confirm the past Motor ON time in the controller status viewer.

3. Calculate a rough offset value with the following formula.

Offset=100

Loading...

Loading...