Part 2 SES 2000 Vac (LS3) AUTOCLAVE

Page 10 of 53 ST-SM45g

PART 2 DESCRIPTION

10 When the door is closed, with the power switched on,

this is sensed by the control board via the door interlock

switch. If any attempt is made to open the door once the

cycle has begun, the display 'ERROR 2' will appear and

an audible signal will sound. Under these circumstances

it is necessary to switch the autoclave off, wait 5 seconds,

reset the error (see Part 3, para. 54) and restart the cycle.

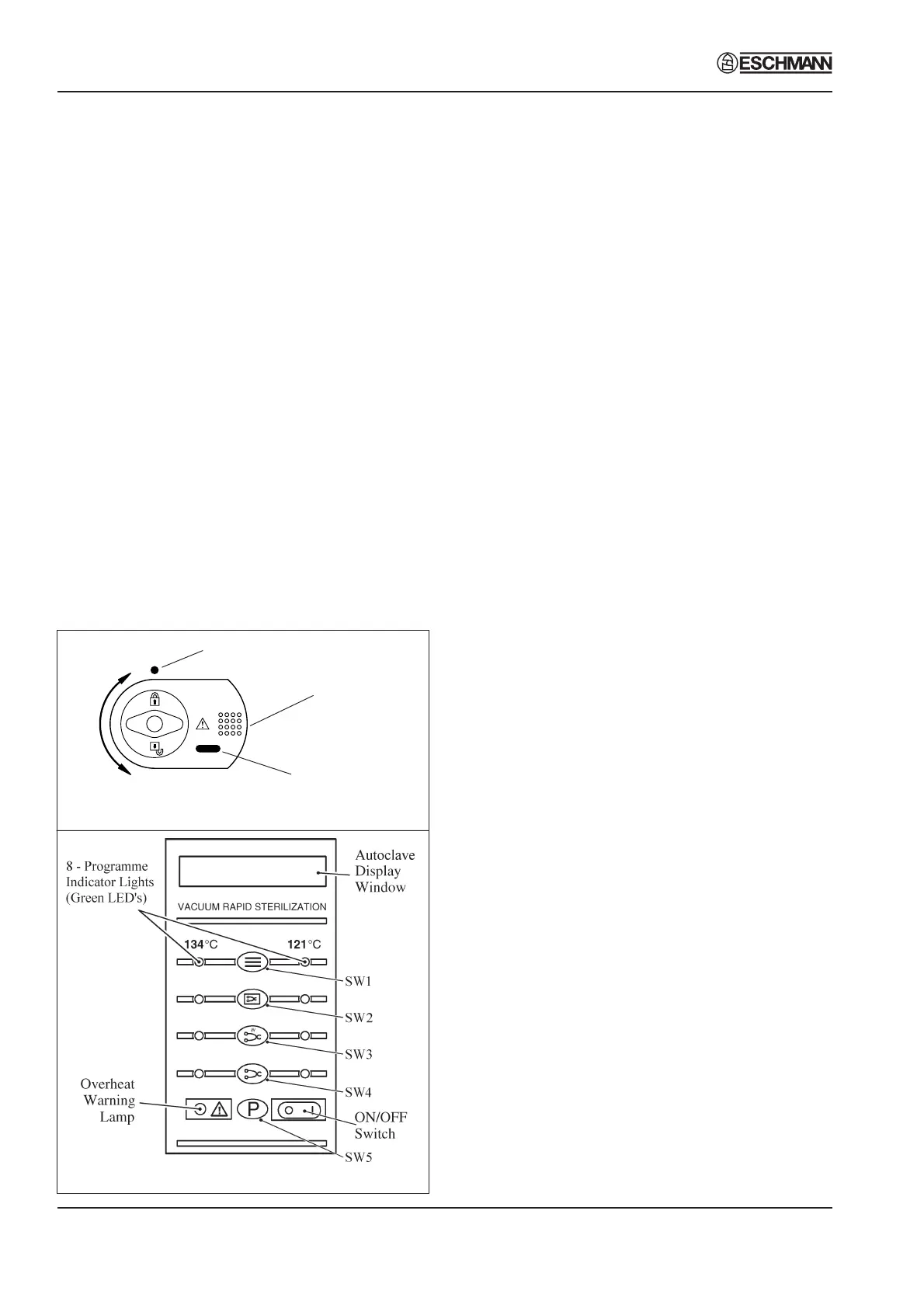

11 The autoclave operates automatically at the touch of

a single programme selector touch button ( Fig. 2.1b), and

has eight programmes:

❑ 134°C Porous load with drying (SW1)

❑ 134°C Wrapped load with drying (SW2)

❑ 134°C Unwrapped load with drying (SW3)

❑ 134°C Unwrapped load (SW4)

❑ 121°C Porous load with drying (SW1)

❑ 121°C Wrapped load with drying (SW2)

❑ 121°C Unwrapped load with drying (SW3)

❑ 121°C Unwrapped load (SW4)

12 Each programme selector button on the control panel

(Fig. 2.1b) will select either the 134°C or 121°C cycles.

The programme indicator lights, at each side of the

programme selector buttons, will change to indicate a

change of selection between 134°C and 121°C each time

the appropriate selector button is pressed. In addition,

the display will show the appropriate programme

description to confirm the programme that has been

selected. Once the programme and the temperature

range has been selected, the sterilization cycle will start

automatically, after a delay of approximately four seconds.

13 The printer, if fitted, will start printing and, as the

cycle progresses, various display messages will appear

in the display window to indicate the programme status.

Note: If a programme is started in error, it can be cancelled

by pressing the 'P' selector button (SW5), provided that the

cycle has not reached the water fill stage.

14 When a cycle is selected (SW1- SW4 pressed),

'CYCLE STARTED' will be displayed, quickly followed by

'VACUUM ON', indicating that the vacuum pump has

started, and the vacuum solenoid valve has opened to

evacuate the air from the chamber.

15 When the pressure in the chamber has decreased to

the required value for the programme selected, the water

fill valve will open and 'FILLING' will be displayed, indicating

that water is being sucked from the reservoir and into the

chamber.

16 When the cycle has started, the door cannot be

opened due to the electric door lock and vacuum force on

the door.

17 When the correct quantity of water has entered the

chamber, the water fill valve closes together with the

vacuum valve. The heater, controlled by the control

board, will switch on, and the pressure in the chamber will

increase. This phase is indicated by 'PULSING' being

shown on the display.

18 The heater is controlled by a system which ensures

that the operating temperature is reached with minimal

overshoot. Initially, the heater will be 'on' continuously

and the measured temperature will be displayed. Note,

however, that the system does not register temperatures

below 92°C.

19 Temperatures are displayed with a resolution of

0.1°C, using signal averaging to ensure a stable, accurate

display.

20 Control of the cycle is fully automatic with temperature

information being monitored by temperature sensors.

Timing is controlled by the control board and cycle times

cannot be adjusted. By comparing measured values with

known time/temperature relationships, the control board

is able to detect faults such as lack of water at the fill

stage, or loss of water and steam during the process, and

Fig. 2.1b Autoclave control panel

Fig. 2.1a Autoclave door handle

Locked

Unlocked

Safety catch

behind door plate

Door lock position

indicator

Chamber pressure

indicator

Loading...

Loading...