5. Operation V10k automatic

22

EN

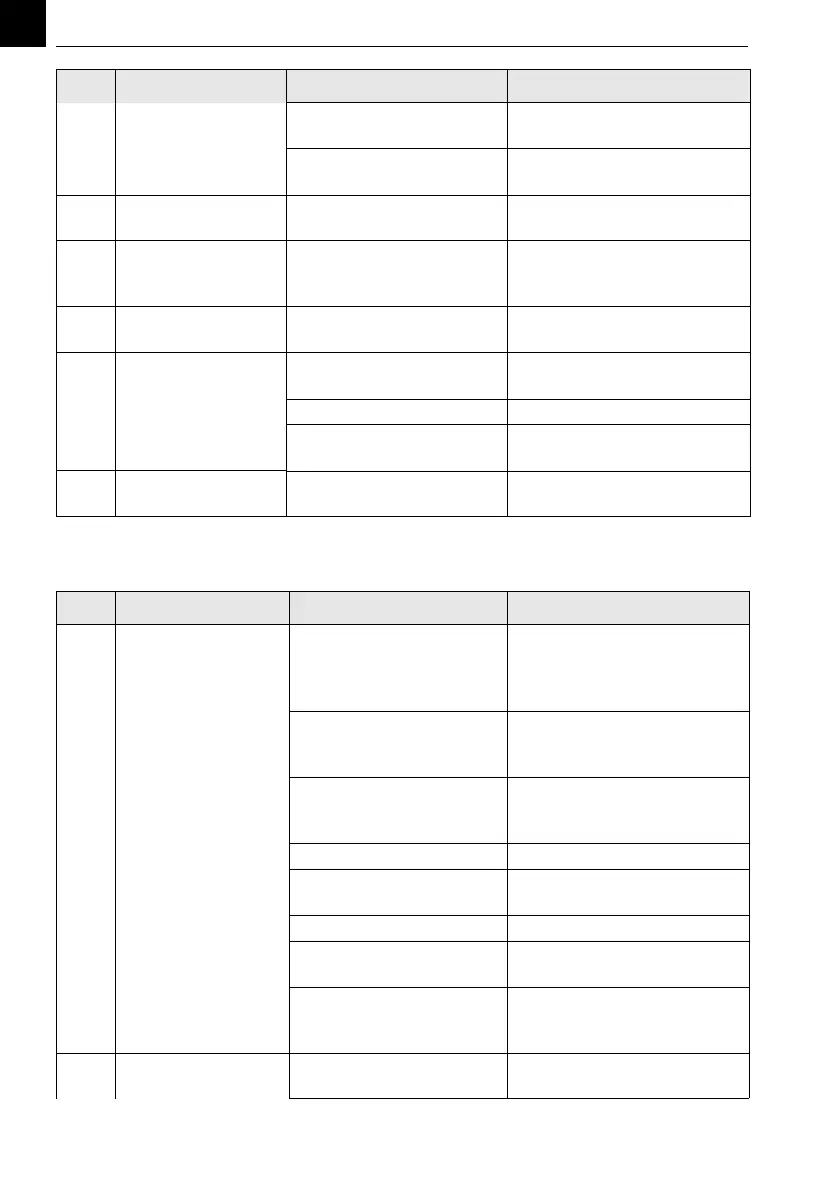

5.6.2 Fault at the positioner and the control

Injector does not meet

requirements.

Change injector parts.

Gas filter in vacuum control

valve clogged.

Replace the filter.

4 Flowmeter float

moves erratically.

Deposits on flowmeter parts. Clean flowmeter.

5 Odour of chlorine in

chlorinator room or

vicinity.

Pressure relief valve blows. Clean resp. replace vacuum

control valve. Replace the filling

of the activated carbon filter.

6 Water in flowmeter Defective check valve in

injector.

Dry the system, check injector.

7 Gas feed rate cannot

be adjusted properly

V-notch stem worn. Replace V-notch stem.

V-notch orifice worn. Replace orifice.

Vacuum control valve defec-

tive.

Replace regulator.

8 Feed rate too high Membrane in differential

control valve broken.

replace W3T165515 (specialist).

No. Symptoms Probable cause Remedy

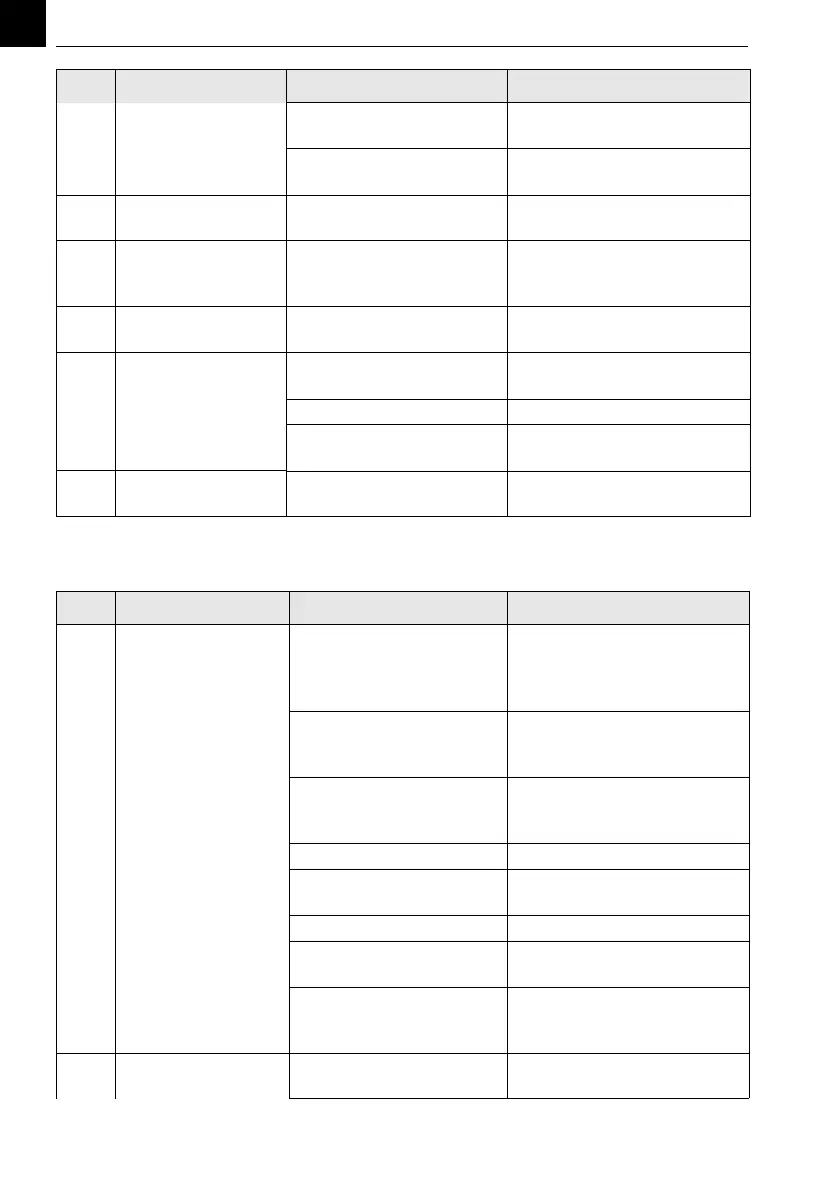

No. Symptoms Probable cause Remedy

1 Rack does not move,

although the positio-

ner receives signal

from the control.

Positioner is in manual ope-

ration (knob is pulled).

Switch to automatic operation

(push the knob).

External separation switch

(optional) is set to OFF or

manual.

Switch to AUTO.

No mains Check the mains from control

unit, mains supply, switches,

fuses.

Rack is blocked Check load (max. 135 N).

Limit switch in the positio-

ner has switched

Check the limits, adjust if neces-

sary.

Motor defective Check the wire resistance.

Gear defective (chattering

noise)

Replace Motor and gear.

Board defective (switches,

capacitor)

Replace board

230 V: part no. W3T173185,

115 V: part no. W3T173203

2 Rack does not move,

although knob turns.

Rack defective (wear) Replace rack.

Loading...

Loading...