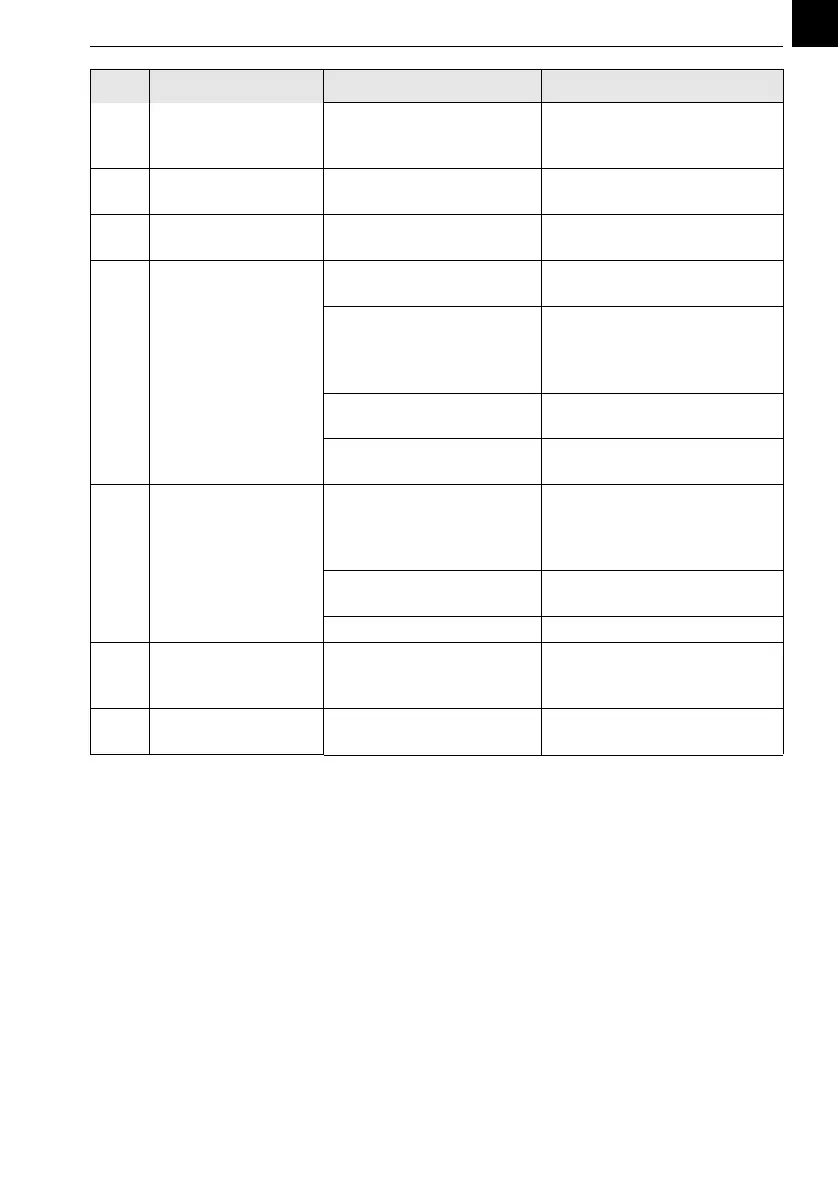

V10k automatic 5. Operation

23

EN

For more information see the manual of the control unit.

Tooth wheel defective Check toothes and clamping of

the tooth wheel, replace

motor-gear if necessary.

3Rack moves to the

wrong direction.

Wrong electric wiring Check the terminals connec-

tions (change terminal 2 and 3)

4Rack moves to the

stop.

Limit switch misadjusted or

defective

Adjust positioner

5Feedback signal can-

not be aligned.

Potentiometer misadjusted Check potentiometer adjust-

ment

Potentiometer defective

(1kOhm ± 10%)

Replace board (Note: special

potentiometer, may not be

replaced by a standard poten-

tiometer)

Wiring and terminals

defective

Check wiring and terminals to

the board

Toothed wheels or potentio-

meter shaft loose

Adjust potentiometer and

clamp toothed wheels

6 Positioner moves

without finding the

right position.

Potentiometer defect or

loose

Check potentiometer resis-

tance while moving the rack by

hand, if necessary replace

potentiometer.

Cable to the control unit

loose

Check the cables.

Capacitor defective Replace the board.

7 Positioner moves fore

and back.

Positioner not correctly

fixed to the mounting plate

or potentiometer loose

Check mounting.

8 Movement too slow Load too great, e.g. by bad

alignment

Check load, check positioner

without load, check alignment.

No. Symptoms Probable cause Remedy

Loading...

Loading...