13

4.0 Structure and function

4.3 Brief description

The Telemag is an electric telescopic pillar with guiding

tubes.

The pillar is used in a complete system and is used exclu-

sively for dynamic centric compression- or eccentric com-

pression-loaded lifting movements.

The telescopic pillar consists of two or three nested guide

tubes which are extended and retracted by an integrated drive.

The guide slide bearings ensure extension and retraction

evenwitho-centeredloads.

Direct current motor with a worm gear drives a threaded

spindle. A threaded nut, which is permanently connected to

the actuator, runs up and down on the spindle and gener-

ates the feed motion. The slide tube is connected on the

front side via the base plate to the guide tubes.

Extension or retraction of the telescopic tube occurs by

changing the rotational direction of the motor. The thrust

speed is dependant on the load.

4.4 Functional principle

Fig. 5

System with control unit

THG/TLG/

TLT

Ewellix

control unit

Power

supply

voltage

Ewellix operating

element

The Telemag telescopic pillar requires an external control to

power the motor unit. It is connected to the THG/TLG via a

connecting cable and to the TLT via two connecting cables.

THG/TLG

ThemaindierencebetweentheTHG/TLGandTLTtele-

scopicpillarsisofthedierentsizesoftheguidetubeand

the number of spindles (refer to chapter 3 Technical data).

The magnitude of the load speed and transverse force de-

termines the choice of drive motors and their power. This ul-

timately results in the deviations in the values for compres-

sive forces and thrust speed as well as additional functions

such as cable feedthroughs.

TLT1

Compared to the Telemag THG and TLG telescopic pillars,

two spindle systems in the TLT telescopic pillar produce

double the thrust speed. There are two connection cables

for two DC motors permanently installed on the TLT tele-

scopic pillar.

NOTE

Additional differences between the THG, TLG and TLT telescopic

pillars are found in the sections on connections and data

sheets in the Appendix.

TLT2

Compared to TLT1, the TLT2 has placed the 2 DC Motors

and Electronic connection outside of the tube to support a

reduced Built in Dimension.

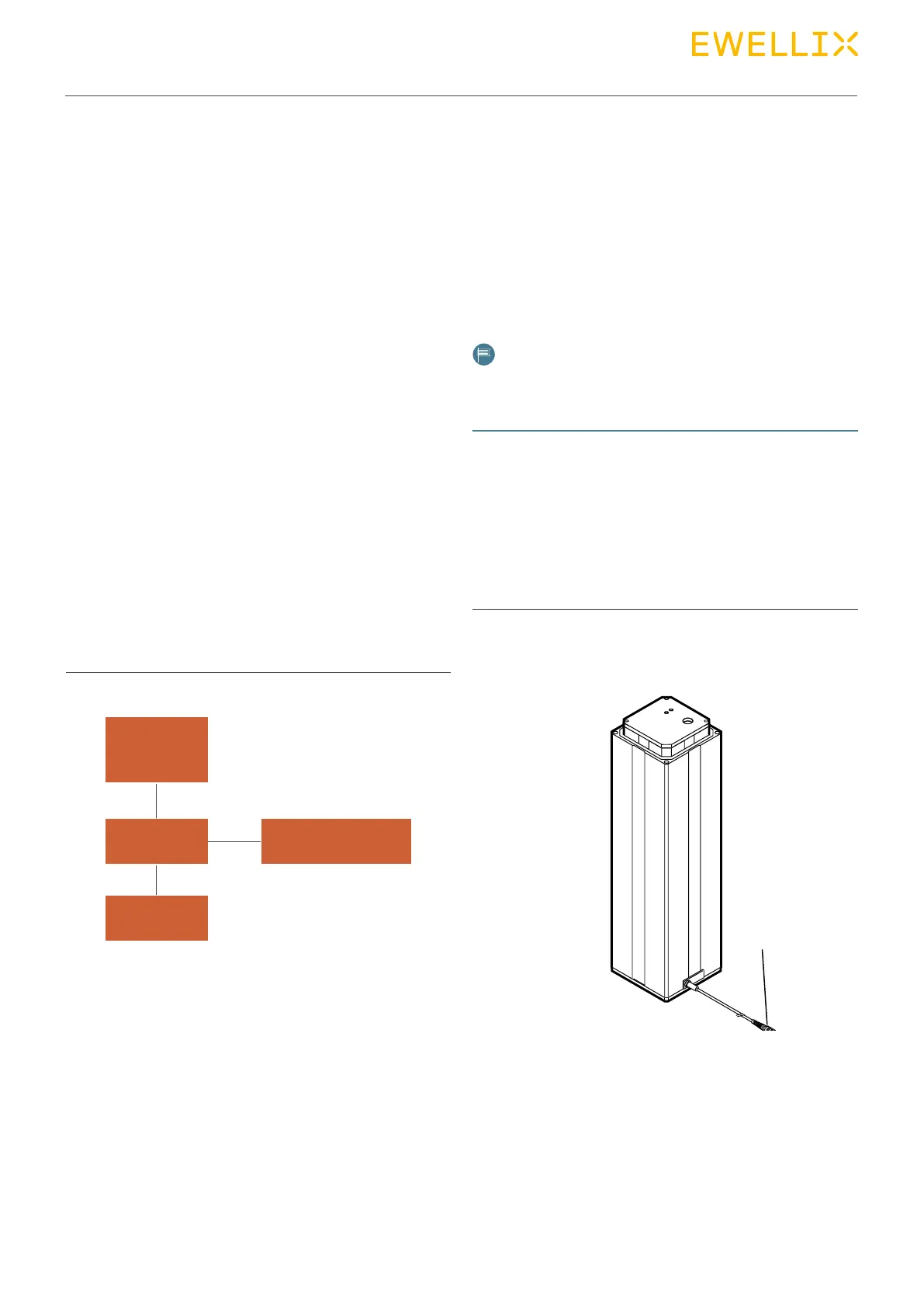

4.5 Connections

Fig. 6

THG/TLG connections

THG/TLG One low voltage plug (1) connect the device to the

power supply via an external Ewellix control.

1. Connections to an external control (jack or DIN-8 plug).

In case of use a third-party control unit see chapter 6.5

Connection to the control unit.

1

Loading...

Loading...