18

THG/TLG/TLT

6.1 Safety

Electrical equipment

WARNING

Life-threatening danger due to electric shock or electrocution

and crush hazard!

There is a life-threatening hazard when touching live components.

Also, live electrical components can move unexpectedly and can

cause serious injuries.

Therefore:

• Priortostartingwork,switchothepowersupplyandsafeguard

it from being re-started. The TLT2 must only be operated with a

suitable current limit board.

Safeguarding against restart

WARNING

Life-threatening danger if restarted without authorization!

When correcting faults, there is danger of the energy supply

being switched on without authorization. This poses a life-

threatening hazard for persons in the danger zone.

Therefore:

• Priortostartingwork,switchothepowersupplyandsafeguard

it from being switched on again.

6.2 Installation position

• Take note of the operating conditions (⮑ Section 3.2).

• The device must not be exposed to strong UV radiation

nor to corrosive or explosive media in the air nor to other

aggressive media.

6.3 Inspection prior to

rst operation

• Tobeperformedbyqualiedpersonnel.

Priortotherstoperation,thefollowingtestsandreadings

have to be performed and documented:

• Check visual the labeling and all designations from cables

and components

• Check visual condition (refer to chapter ⮑ 8.3.2 Visual

check of condition).

• Function check of operating features and safety features.

NOTE

Additional information concerning inspections and

readings (refer to chapter ⮑ 8 Maintenance).

6.4 Installation

• Tobeperformedbyqualiedpersonnel.

WARNING

Risk of injury and property damage due to manipulation of

the screws on the device

Manipulation or loosening the screws on the pillar or on the options

can cause injuries and damage during operation.

Therefore:

• Never loosen screws on the device (except transport screws, see

next page).

The telescopic pillar is attached to the Ewellix attachment

plates (accessories) or to plates supplied by the customer on

the application.

NOTE

When using your own attachment plates, install

them according to the technical data sheets (⮑ Appendix).

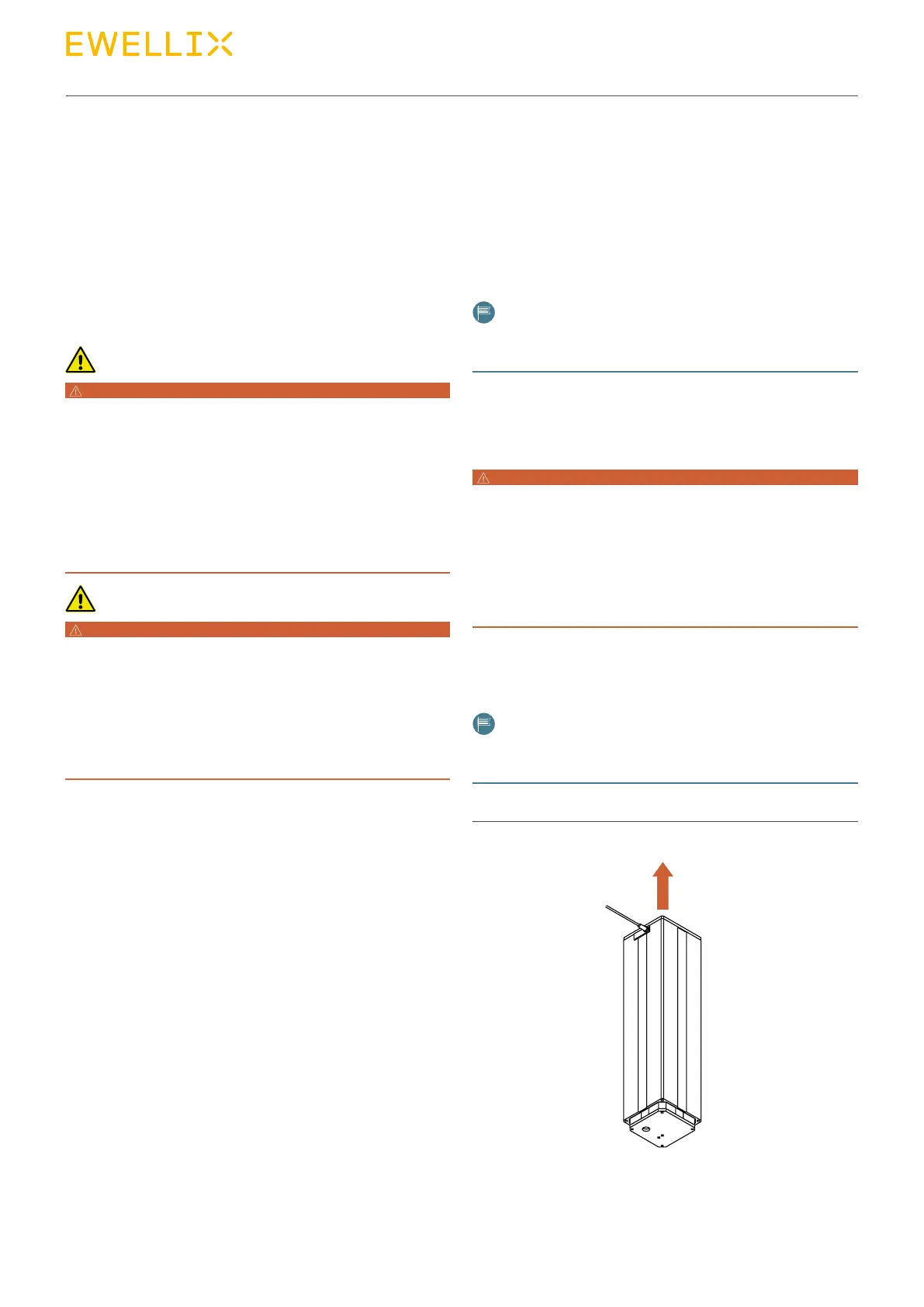

Fig. 10

Alignment of the pillar (mounting position 180 °C turned

permitted)

6.0 Installation and initial

operational set-up

Loading...

Loading...